Coil coating and preparation method thereof

A technology of coil coatings and pigments, applied in the direction of anti-corrosion coatings, fireproof coatings, polyester coatings, etc., can solve the problems of poor acid and alkali resistance, poor scratch resistance, low flexibility, etc., to achieve enhanced adhesion, low cost, easily degradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

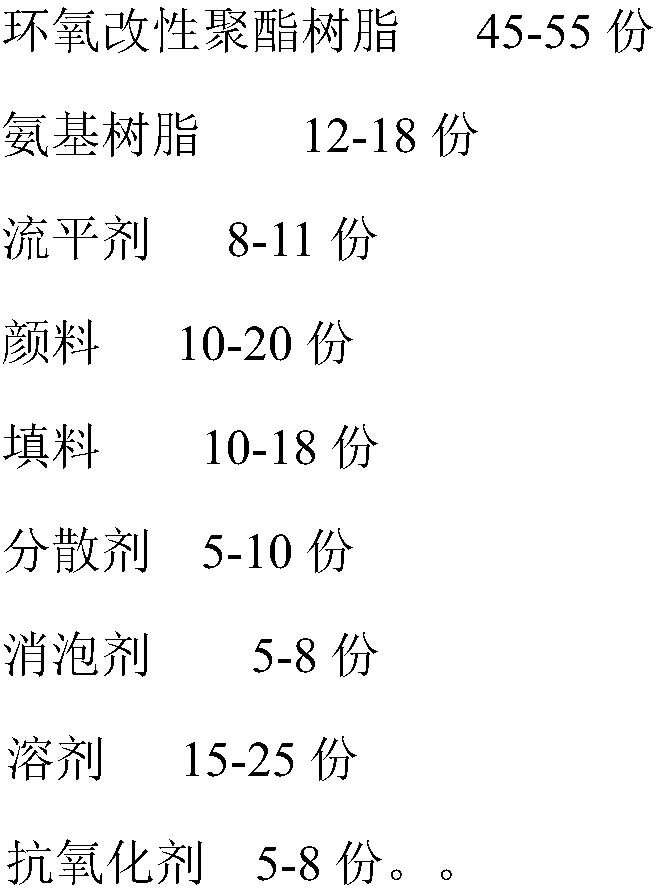

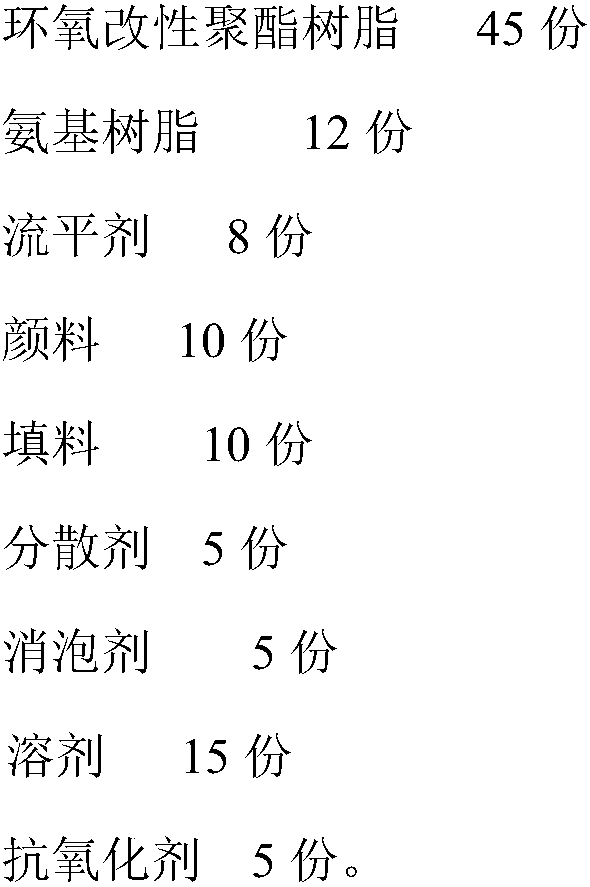

[0033] A coil coating of this embodiment includes the following components:

[0034]

[0035] The amino resin is composed of a fully methyl etherified amino resin and a butyl etherified amino resin in a mass ratio of 3:1.

[0036] The dispersant is composed of polydimethylsiloxane and ethylene-vinyl acetate copolymer in a mass ratio of 1:1.5, and the leveling agent is polyether modified polydimethylsiloxane.

[0037] The defoamer is composed of polyether modified silicone and polysiloxane in a mass ratio of 3:2; the solvent is composed of xylene, heavy aromatic hydrocarbons containing C9-C10, and cyclohexanone in a mass ratio of 2:5: 3 composition.

[0038] The antioxidant is composed of the following components: 10 parts of soybean oil, 5 parts of tert-butanol, and 5 parts of liquid paraffin.

[0039] The filler is composed of self-cleaning material and flame retardant in a mass ratio of 1:4; the self-cleaning material is composed of silver vanadate, nano titanium dioxide, and nano zi...

Embodiment 2

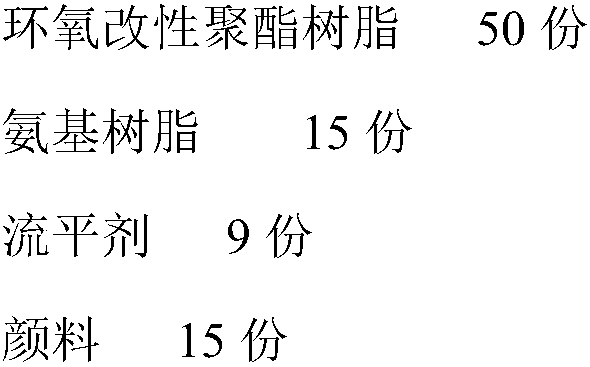

[0042] The water-based epoxy resin refractory coating of this embodiment includes the following components:

[0043]

[0044]

[0045] The amino resin is composed of a fully methyl etherified amino resin and a butyl etherified amino resin in a mass ratio of 3:1.

[0046] The dispersant is composed of polydimethylsiloxane and ethylene-vinyl acetate copolymer in a mass ratio of 1:1.5, and the leveling agent is polyether modified polydimethylsiloxane.

[0047] The defoamer is composed of polyether modified silicone and polysiloxane in a mass ratio of 3:2; the solvent is composed of xylene, heavy aromatic hydrocarbons containing C9-C10, and cyclohexanone in a mass ratio of 2:5: 3 composition.

[0048] The antioxidant is composed of the following components: 10 parts of soybean oil, 5 parts of tert-butanol, and 5 parts of liquid paraffin.

[0049] The filler is composed of self-cleaning material and flame retardant in a mass ratio of 1:4; the self-cleaning material is composed of silver van...

Embodiment 3

[0052] The water-based epoxy resin refractory coating of this embodiment includes the following components:

[0053]

[0054] The amino resin is composed of a fully methyl etherified amino resin and a butyl etherified amino resin in a mass ratio of 3:1.

[0055] The dispersant is composed of polydimethylsiloxane and ethylene-vinyl acetate copolymer in a mass ratio of 1:1.5, and the leveling agent is polyether modified polydimethylsiloxane.

[0056] The defoamer is composed of polyether modified silicone and polysiloxane in a mass ratio of 3:2; the solvent is composed of xylene, heavy aromatic hydrocarbons containing C9-C10, and cyclohexanone in a mass ratio of 2:5: 3 composition.

[0057] The antioxidant is composed of the following components: 10 parts of soybean oil, 5 parts of tert-butanol, and 5 parts of liquid paraffin.

[0058] The filler is composed of self-cleaning material and flame retardant in a mass ratio of 1:4; the self-cleaning material is composed of silver vanadate, na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com