Photosensitive ink material and preparation method thereof

A technology of ink and photosensitive resin, applied in the field of ink materials, can solve problems such as lack of mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

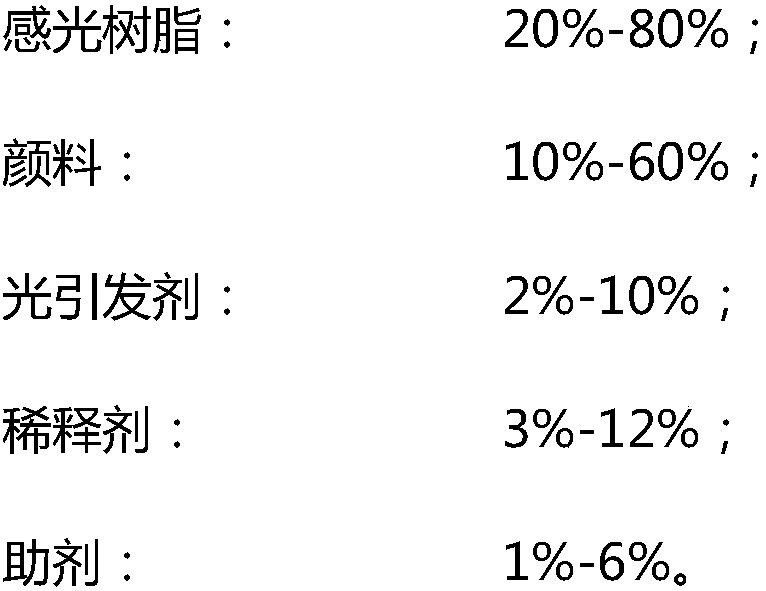

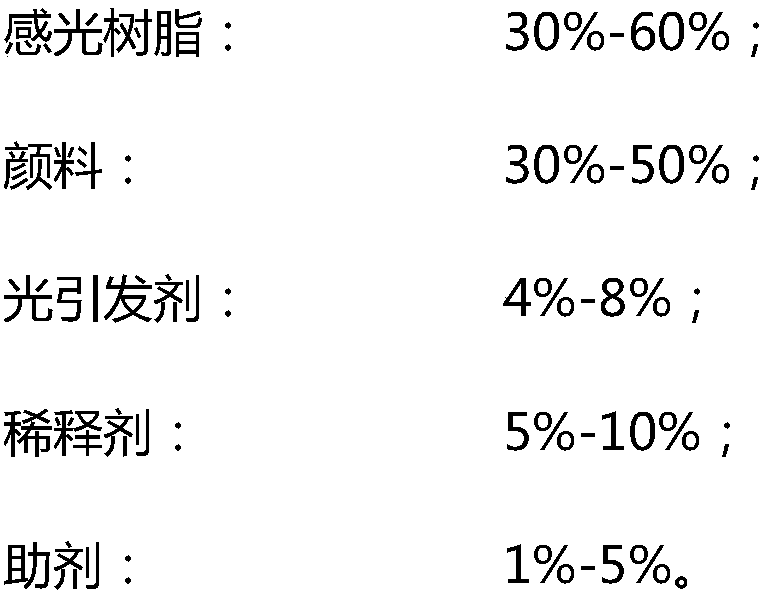

Method used

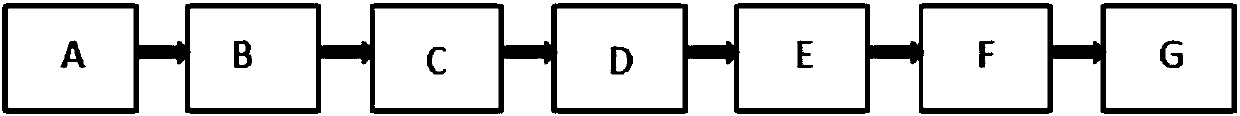

Image

Examples

Embodiment 1

[0086] The preparation method of basic embodiment 1 hyperbranched photosensitive resin

[0087] The hyperbranched photosensitive resin is a photosensitive resin obtained through an esterification reaction between a hyperbranched matrix containing a terminal hydroxyl group and a monomer containing a carboxyl group, and the specific reaction equation is (B);

[0088]

[0089] In the above-mentioned reaction equation, HBP is the abbreviation form of hyperbranched resin, and concrete molecular formula is following formula (I);

[0090] HBP:

[0091]

Embodiment 2

[0092] The preparation method of the acetoacetate compound of basic embodiment 2β-dicarboxyl structure

[0093] The self-crosslinking curable photosensitive resin is an acetoacetate compound based on a β-dicarboxyl structure;

[0094] The polyhydroxy macromolecular compound is mixed with a monoacetoacetate compound or a diacetoacetate compound, and then a catalyst is added as a reaction material, which is synthesized by microwave irradiation; the monoacetoacetate compound is The compound containing the basic structure of formula (II), the described diacetoacetate compound is a compound containing the basic structure of formula (III),

[0095]

[0096] Wherein, R1 is a tertiary alcohol or pinacol.

[0097] The polyhydroxy macromolecular compound can be selected from chitosan, dextran or hyaluronic acid.

Embodiment 3

[0098] The preparation method of the polymer microsphere of basic embodiment 3 cutting stabilizer

[0099] The preparation process of the polymer microspheres of the excised stabilizer is as follows:

[0100] Using Z-type macromolecular RAFT reagent as a stable dispersant, ethanol / water mixture as a dispersion medium, and 10% of 4-acryloylmorpholine (ACMO), 6% of methacrylic acid (MAA) and 6% of A mixture of glycidyl methacrylate (GMA) and 6% methacrylic acid (MAA) is used as a monomer for light dispersion polymerization to synthesize a stable white milky dispersion; then dilute with water and add excess thermal initiator diisopropyl Benzene peroxide is heated in a nitrogen oil bath for 20-28h, and the clean polymer functional microspheres whose surface does not contain a stable dispersant are obtained after removing the dispersion medium; the structural formula (II') of the Z-type macromolecule RAFT reagent is as follows:

[0101]

[0102] The preparation method of basic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com