Permanent antibiosis mildew-resistant nontoxicity and innocuousness polyester material and preparation method thereof

An antibacterial, mildew-proof, non-toxic and harmless technology, applied in the field of materials, can solve the problems of lack of clear explanation, limited heat resistance, risk of bacterial and mold resistance, and improve the quality of life and health, and the antibacterial effect is reliable. , Improve the effect of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

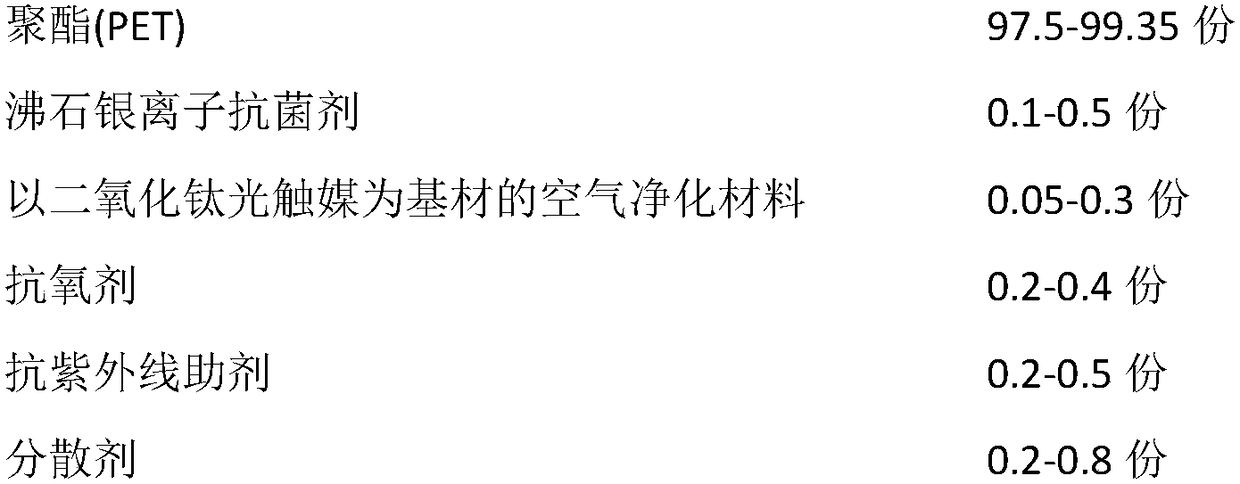

Method used

Image

Examples

Embodiment 1

[0035] (1) In terms of parts by mass, first mix 0.2 parts of zeolite silver ion antibacterial agent (IM10D-F) and 0.1 part of air purification material based on titanium dioxide photocatalyst (from Chinese invention patent example 1, patent number is 201610066352.6) Dry at 90°C for 2 hours, then put the dried two substances into a high-speed mixer, add 0.18 parts by weight of new active silicone powder, control the temperature at 100°C, and process for 30 minutes to obtain A materials.

[0036] (2) Dry the bottle-grade polyester at 170°C for 2 hours for later use. In terms of parts by mass, 98.67 parts of bottle-grade polyester chips, 0.25 parts of antioxidant (1010:168=0.15:0.1), 0.3 parts of anti-ultraviolet additive UV234 and 0.3 parts of new active silicone powder (RM4‐ 7051) was added into a high-speed mixer, blended for 5 minutes, and stirred evenly to obtain material B.

[0037] (3) Add material B from the main feeding port of the twin-screw extruder, add material A f...

Embodiment 2

[0039] (1) In terms of parts by mass, first mix 0.22 parts of zeolite silver ion antibacterial agent (IM10D-F) and 0.13 parts of air purification material based on titanium dioxide photocatalyst (from Chinese invention patent example 1, patent number is 201610066352.6) Dry at 90°C for 2 hours, then put the dried two substances into a high-speed mixer, add 0.22 parts by weight of new active silicone powder, control the temperature at 100°C, and process for 30 minutes to obtain A materials.

[0040] (2) Dry the bottle-grade polyester at 170°C for 2 hours for later use. In terms of parts by mass, 98.58 parts of fiber-grade polyester chips, 0.25 parts of antioxidant (1010:168=0.15:0.1), 0.3 parts of anti-ultraviolet additive UV234 and 0.3 parts of new active silicone powder (RM4‐ 7051) was added into a high-speed mixer, blended for 5 minutes, and stirred evenly to obtain material B.

[0041] (3) Add material B from the main feeding port of the twin-screw extruder, add material A...

Embodiment 3

[0043] (1) In terms of parts by mass, first mix 0.22 parts of zeolite silver ion antibacterial agent (IM10D-F) and 0.13 parts of air purification material based on titanium dioxide photocatalyst (from Chinese invention patent example 1, patent number is 201610066352.6) Dry at 90°C for 2 hours, then put the dried two substances into a high-speed mixer, add 0.22 parts by weight of new active silicone powder, control the temperature at 100°C, and process for 30 minutes to obtain A materials.

[0044] (2) Dry the film-grade polyester at 170°C for 2 hours for later use. In terms of parts by mass, 98.58 parts of film-grade polyester chips, 0.25 parts of antioxidant (1010:168=0.15:0.1), 0.3 parts of anti-ultraviolet additive UV234 and 0.3 parts of new active silicone powder (RM4‐ 7051) was added into a high-speed mixer, blended for 5 minutes, and stirred evenly to obtain material B.

[0045] (3) Add material B from the main feeding port of the twin-screw extruder, add material A fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com