Plug flow reaction device for stable operation of nitrosation-anaerobic ammoxidation technology, and method thereof

A technology of anaerobic ammonium oxidation and stable operation, applied in the field of plug-flow reaction devices, can solve problems such as difficult stable operation and nitrate accumulation, and achieve the effect of improving effluent water quality and increasing biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

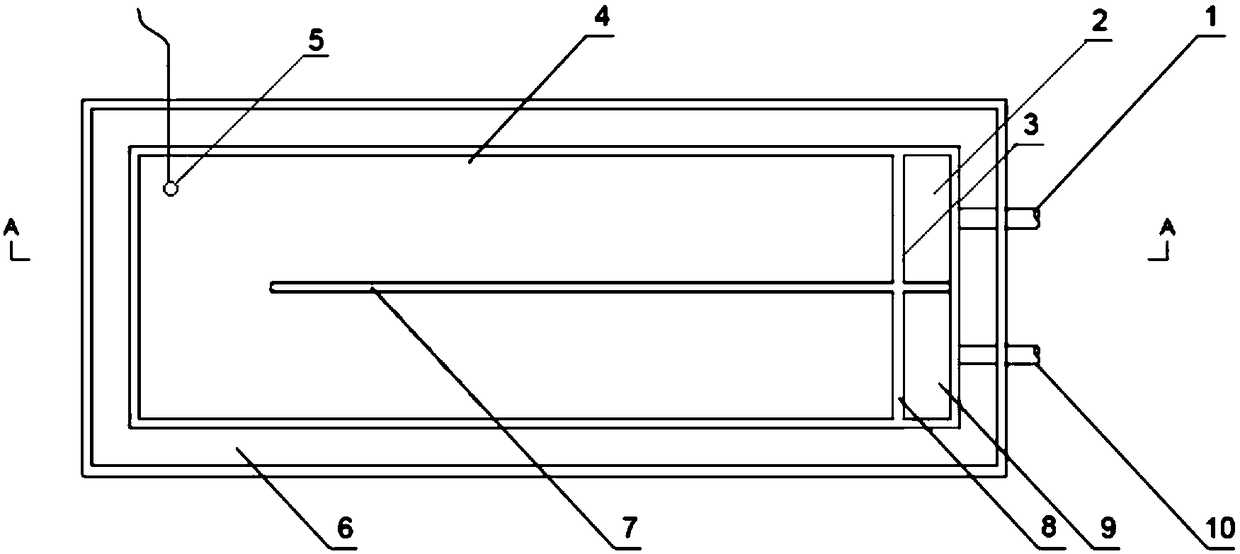

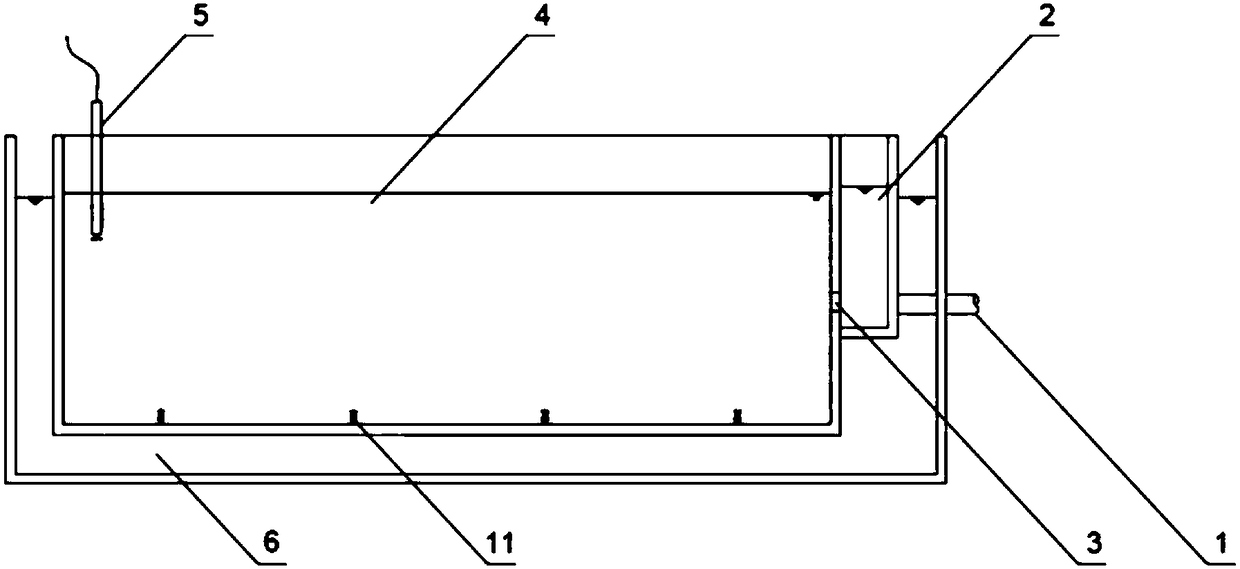

[0029] Specific Embodiment 1: The push-flow reaction device for the stable operation of the nitrosation-ANAMMOX process in this embodiment includes: water inlet pipe 1, water inlet tank 2, water inlet hole 3, fixed packing tank 4, dissolved oxygen temperature online monitoring probe 5. Water bath heating device 6, corridor partition 7, outlet weir 8, outlet tank 9, outlet pipe 10 and aeration head 11,

[0030] One end of the fixed stuffing tank 4 is connected with the water inlet tank 2 and the water outlet tank 9, the end face where the fixed stuffing tank 4 is connected with the water inlet tank 2 is provided with a water inlet hole 3, and the end face where the fixed stuffing tank 4 is connected with the water outlet tank 9 is provided with There is an outlet weir 8, an inlet pipe 1 is provided on the inlet tank 2, and the inlet pipe 1 passes through the water bath heating device 6, an outlet pipe 10 is arranged on the outlet tank 9, and the outlet pipe 10 passes through the...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the corridor is filled with fixed fillers, and the dissolved oxygen temperature online monitoring probe 5 is inserted into the fixed fillers. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the fixed filler is a polyurethane sponge connected in series by copper wires and fixed on a steel frame, and then the steel frame is placed in the corridor. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com