Preparation method of ZnLiMgO nanoparticles and product prepared from ZnLiMgO nanoparticles

A technology of nano-particles and magnesium salts, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, inorganic chemistry, etc., can solve problems such as short life, high energy consumption of light-emitting devices, and failure to meet the requirements of the display industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Including the following steps:

[0027] S1, at 25° C., mix 6 mmol of lithium acetate dihydrate and 20 mL of ethylene glycol methyl ether, and in addition, add 6 mmol of tetramethylammonium hydroxide pentahydrate to obtain a first reaction system.

[0028] S2: Add 4mmol of zinc acetate dihydrate to the first reaction system and stir for 2h to obtain a ZnLiO dispersion system.

[0029] S3: Add 0.6 mmol of magnesium acetate tetrahydrate to the ZnLiMgO dispersion system of S2, the temperature of the water bath is 15 DEG C, and the ultrasonic for 20 min, to obtain ZnLiMgO nanoparticles.

[0030] Ethylene glycol methyl ether as a surface ligand is attached to the surface of ZnLiMgO nanoparticles.

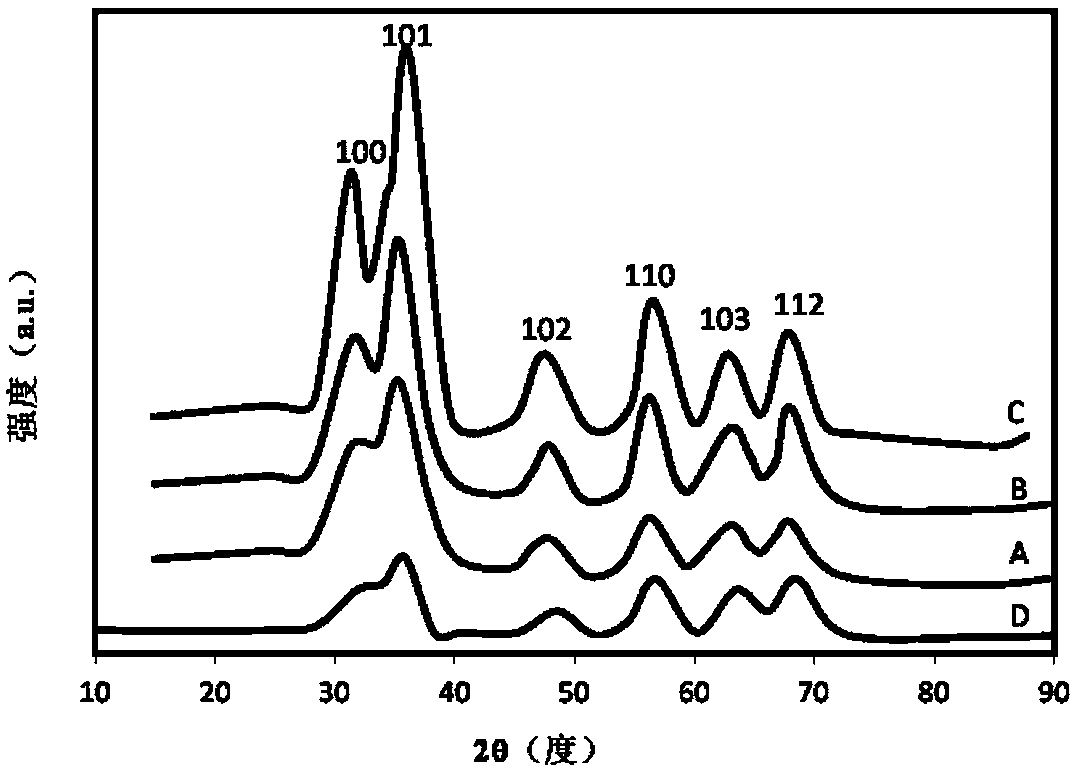

[0031] According to ICP-MS test, the molar ratio of Zn, Li and Mg in ZnLiMgO is 100:24:28. After XRD test analysis (such as figure 1 As shown in curve A), the ZnLiMgO nanoparticles have a wurtzite structure. After calculation, the band gap width of ZnLiMgO nanoparticles is 3.57eV. The ca...

Embodiment 2

[0034] Including the following steps:

[0035] S1, at 22° C., mix 6 mmol of lithium acetate dihydrate and 20 mL of ethylene glycol propyl ether, and add 6 mmol of tetramethylammonium hydroxide pentahydrate to obtain the first reaction system.

[0036] S2: Add 4 mmol of zinc acetate dihydrate and 0.2 mmol of magnesium acetate tetrahydrate to the first reaction system, and stir for 2 hours to obtain a ZnLiMgO dispersion system.

[0037] S3: Add 0.4 mmol magnesium acetate tetrahydrate to the ZnLiMgO dispersion system of S2, the temperature of the water bath is 20 DEG C, and the ultrasonic for 45 min, to obtain ZnLiMgO nanoparticles.

[0038] Ethylene glycol propyl ether is attached to the surface of ZnLiMgO nanoparticles as a surface ligand.

[0039] According to the ICP-MS test, the molar ratio of Zn, Li and Mg in ZnLiMgO is 100:16:23. After XRD test analysis (such as figure 1 As shown by curve B), the ZnLiMgO nanoparticles have a wurtzite structure. After calculation, the band gap wid...

Embodiment 3

[0042] Including the following steps:

[0043] S1, at 23° C., mix 3 mmol of lithium sulfate, 10 mL of ethylene glycol methyl ether and 10 mL of PEG200, and also add 3 mmol of tetramethylammonium hydroxide pentahydrate to obtain the first reaction system.

[0044] S2: Add 3 mmol of zinc acetate dihydrate and 0.1 mmol of magnesium nitrate to the first reaction system, and stir for 0.5 h to obtain a ZnLiMgO dispersion system.

[0045] S3: Add 0.2 mmol magnesium nitrate to the ZnLiMgO dispersion system of S2, and the temperature of the water bath is 35° C. and ultrasonic for 60 min to obtain ZnLiMgO nanoparticles.

[0046] Ethylene glycol methyl ether as a surface ligand is attached to the surface of ZnLiMgO nanoparticles.

[0047] According to ICP-MS testing, the molar ratio of Zn element, Li element and Mg element in ZnLiMgO is 100:7:12. After XRD test analysis (such as figure 1 As shown by the middle C curve), the ZnLiMgO nanoparticles have a wurtzite structure. After calculation, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com