Loading device for entirely applying simulative load to ocean work-over rig

A technology of loading device and workover rig, applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problems of economy, safety, efficiency, test work effectiveness and overall decline, drilling and workover The main structure of the machine is not fully loaded, etc., to achieve the effect of ensuring comprehensiveness and effectiveness, comprehensive functions and applicability, and improving economy and safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

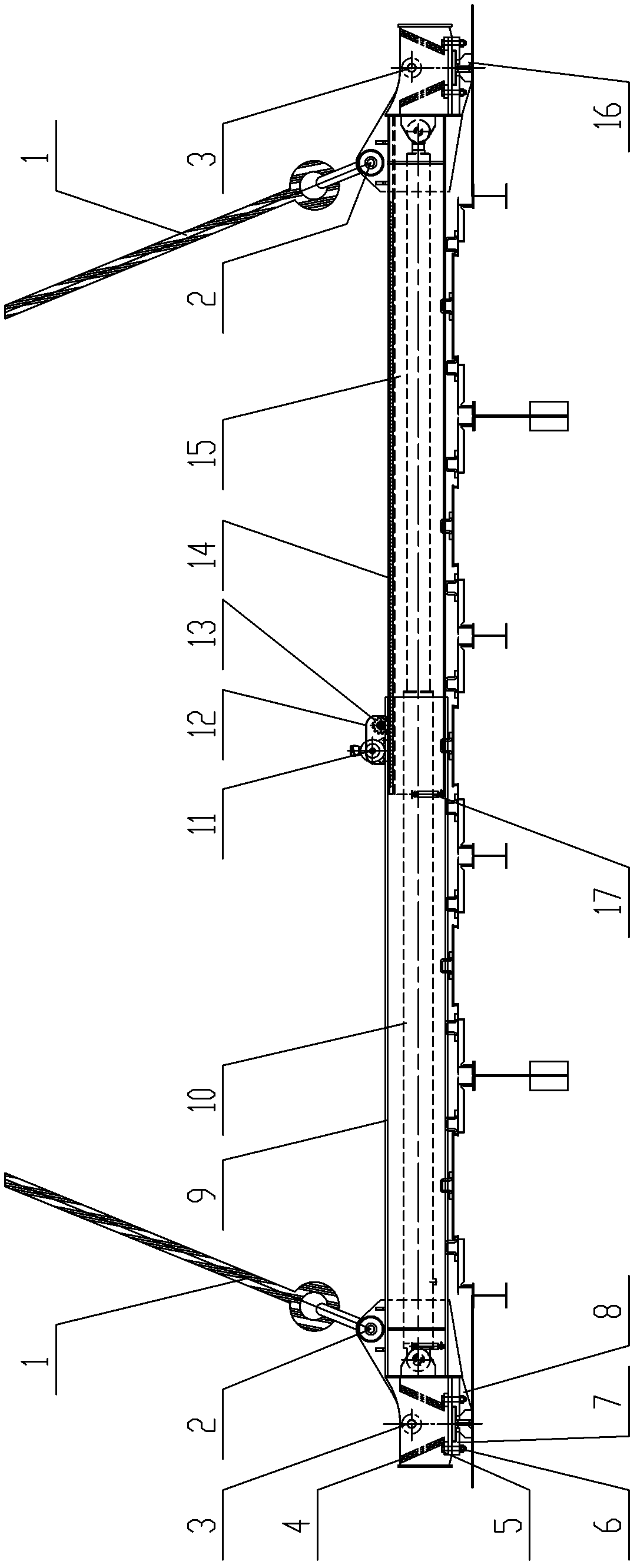

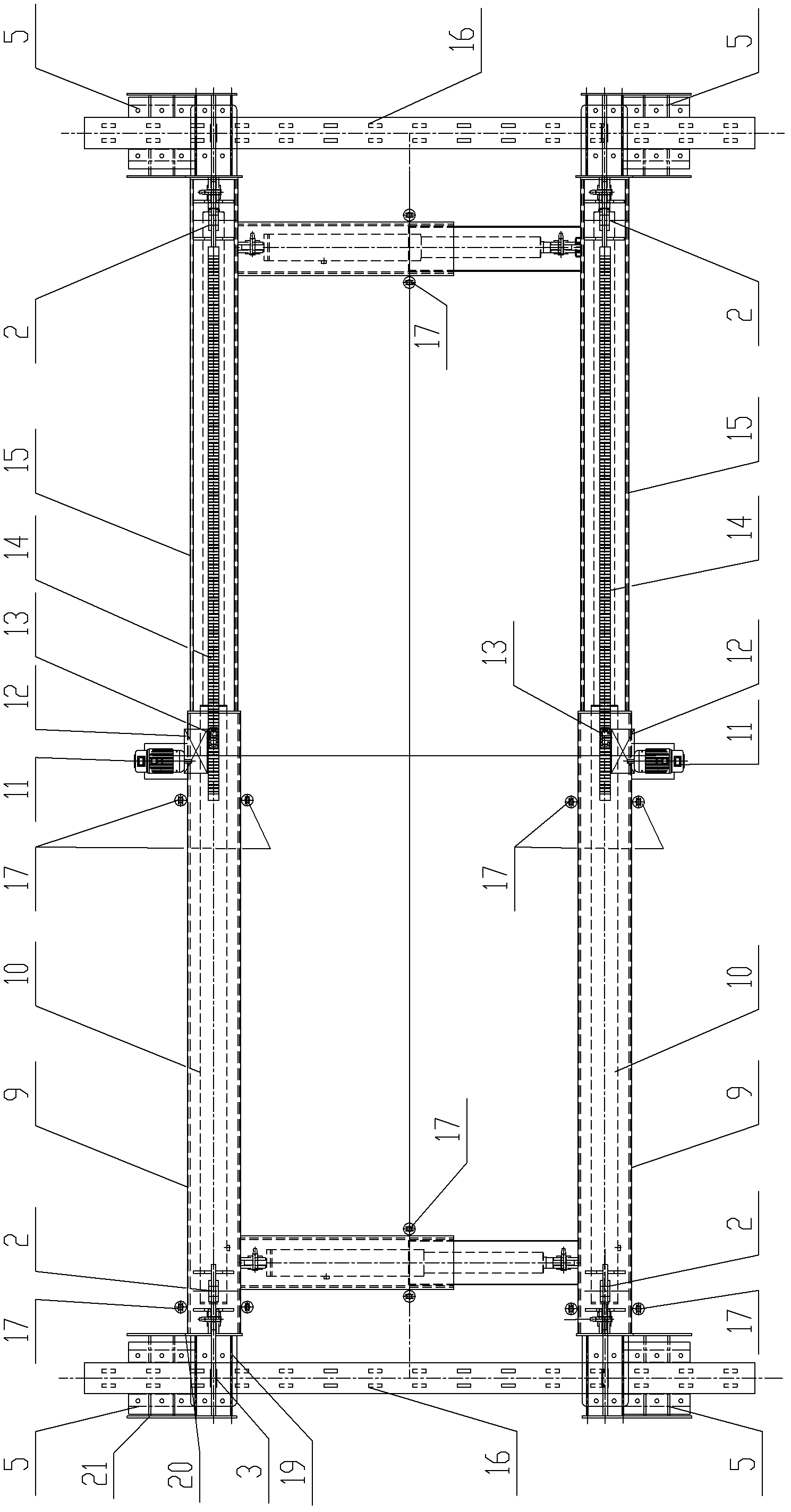

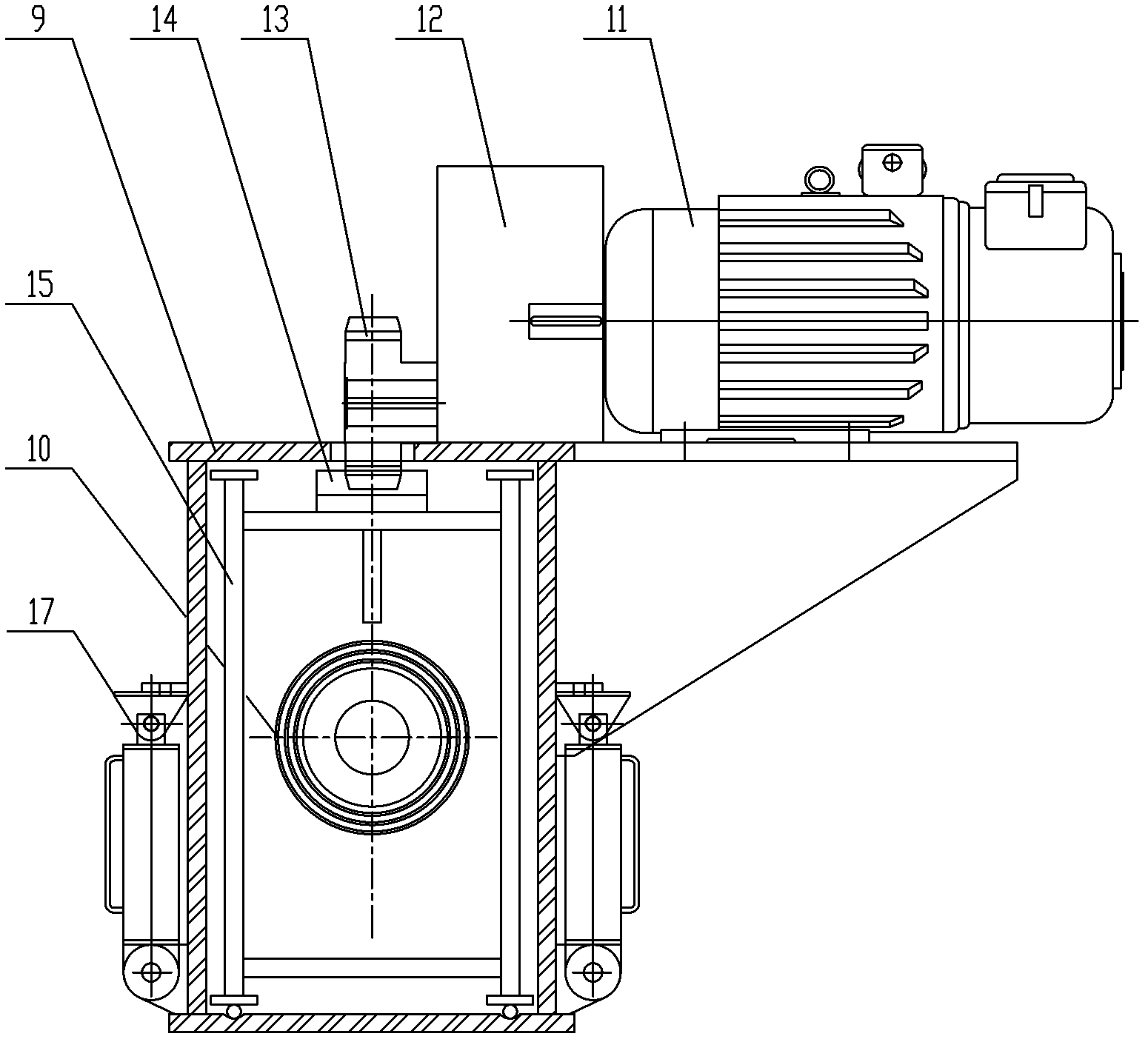

[0034] see Figure 1 to Figure 7, a loading device for applying simulated loads on the whole of the marine workover rig includes a front beam and a rear beam symmetrically arranged on both sides of the X-axis, and a left beam symmetrically arranged on both sides of the Y-axis is arranged between the front beam and the rear beam. The longitudinal beam and the right longitudinal beam, the front beam and the rear beam are fixedly connected between the sliding guide rails 16 of the two platforms, and each beam end is fixedly connected with a support leg of the lower base of a workover rig. The base has four supporting legs. Both ends of the front crossbeam and the rear crossbeam are provided with four connecting devices correspondingly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com