Injection molding machine

A technology for injection molding machines and tube heads, which is applied in the field of injection molding equipment, can solve the problems of long maintenance time and reduced processing efficiency of injection molding machine nozzles, and achieve the effects of shortening maintenance and replacement time, short replacement time and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

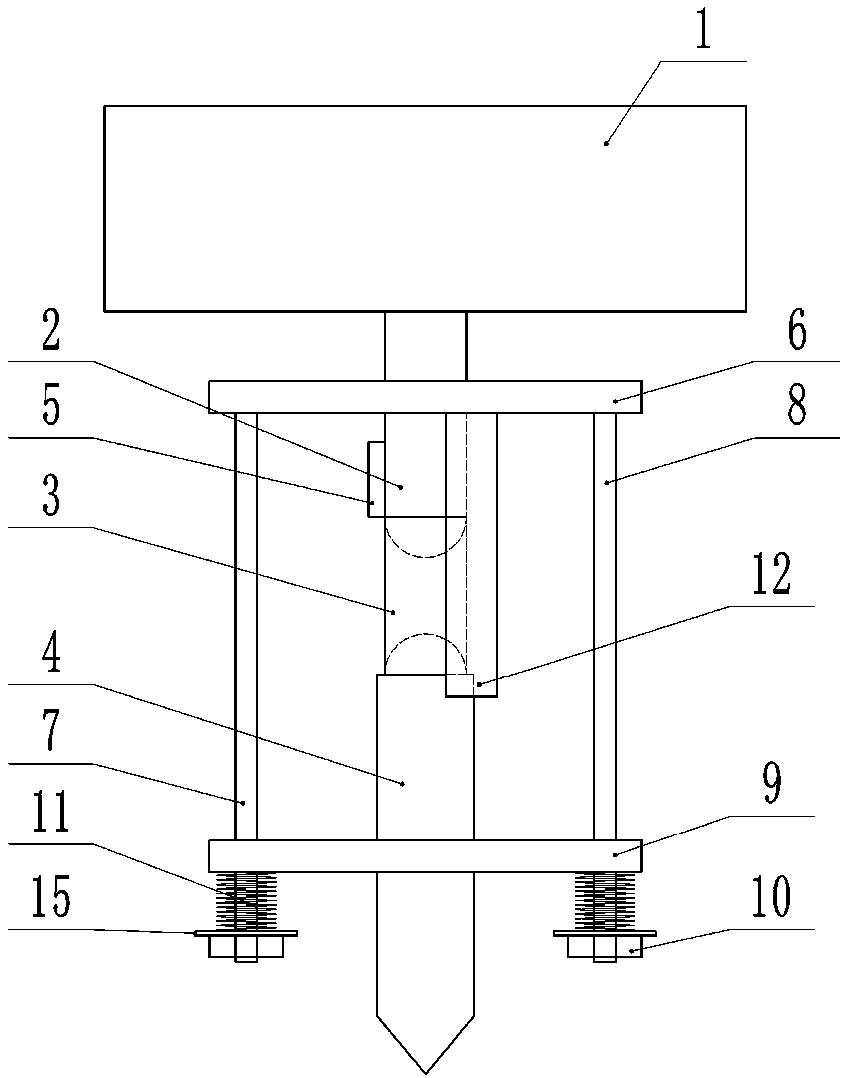

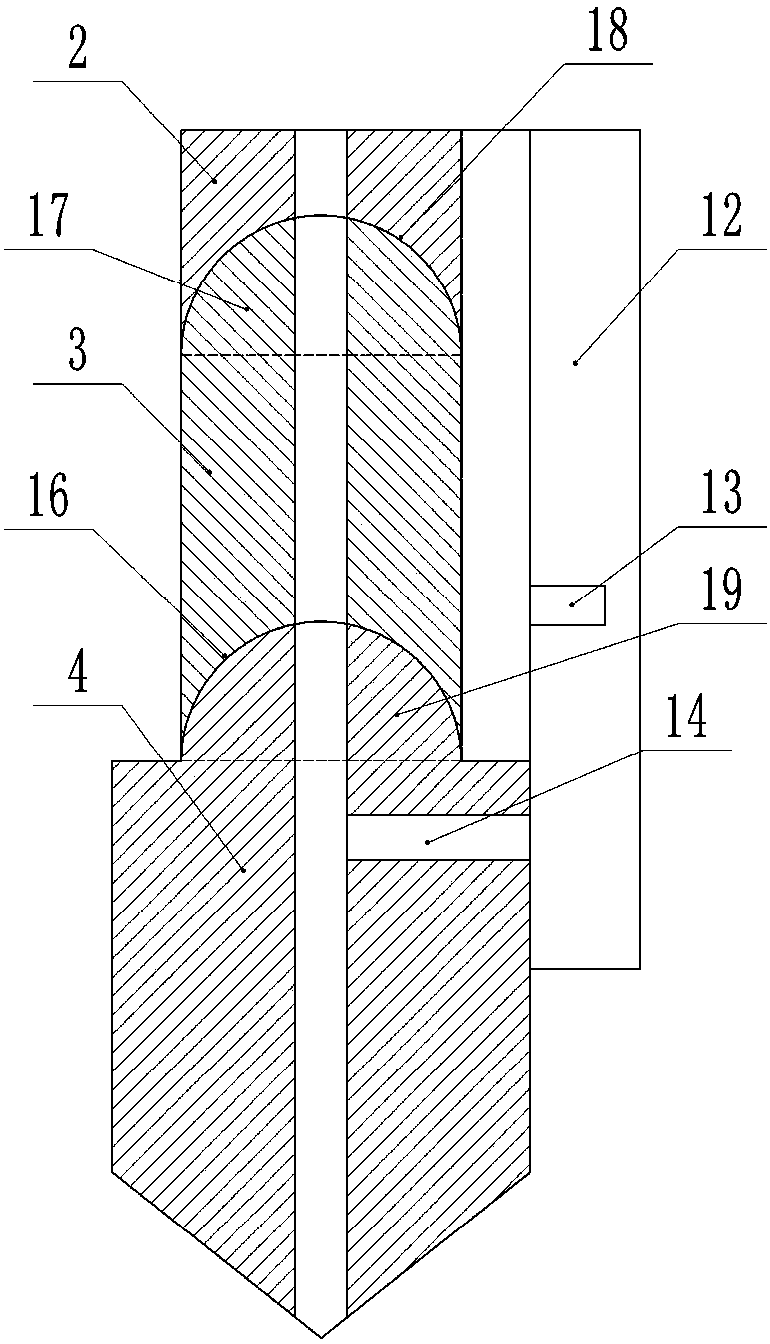

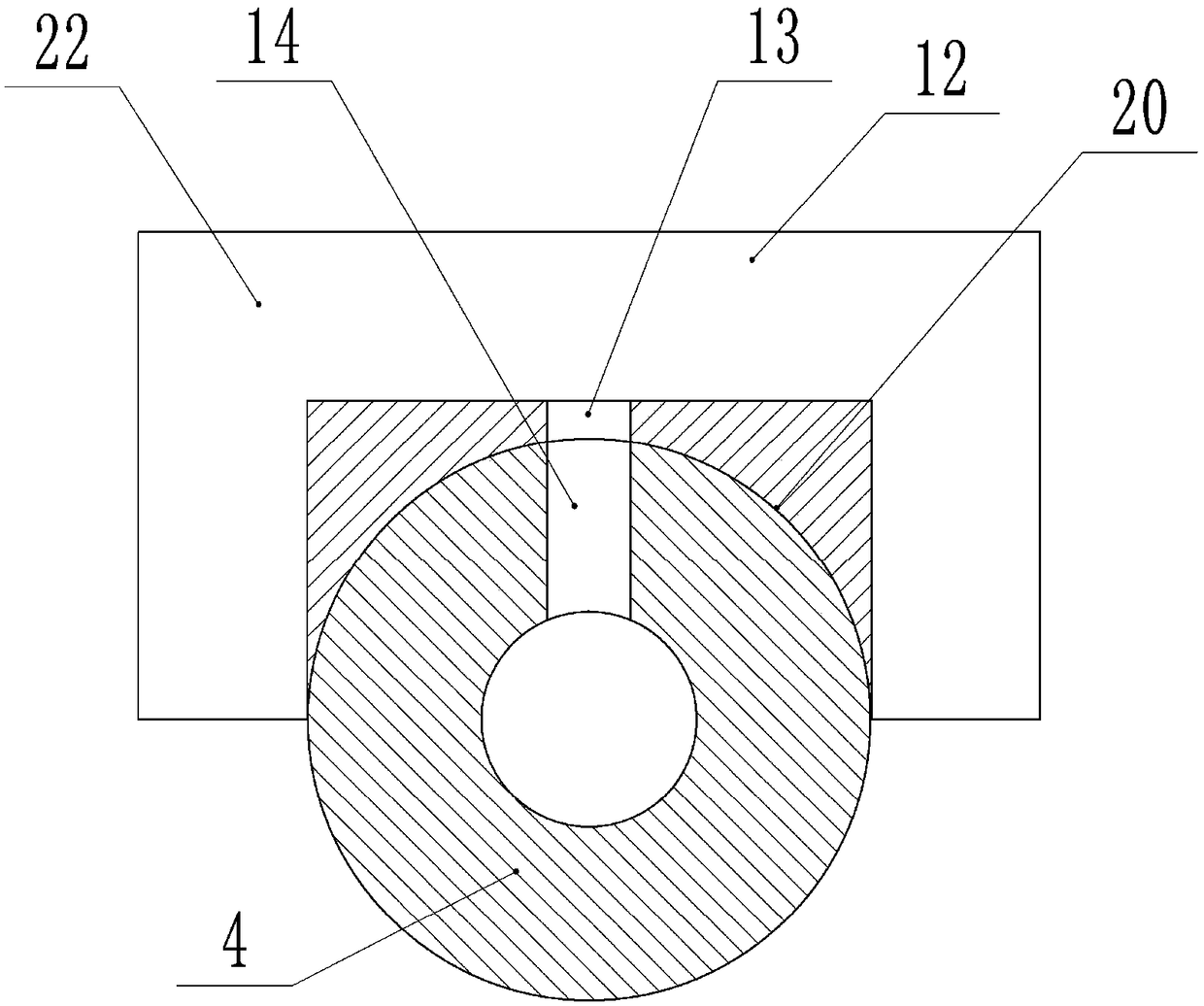

[0020] The reference signs in the accompanying drawings of the description include: storage tank 1, first pipe head 2, second pipe head 3, third pipe head 4, rubber sleeve 5, first horizontal plate 6, first vertical bar 7, first Two vertical rods 8, second horizontal plate 9, nut 10, first spring 11, fixed plate 12, first through hole 13, third through hole 14, gasket 15, first groove 16, first protrusion 17 , the second groove 18 , the second protrusion 19 , the third groove 20 , the baffle plate 21 , and the cavity structure 22 .

[0021] Such as figure 1 As shown, an injection molding machine includes a material storage box 1, the lower part of the material storage box 1 is connected with a first pipe head 2, a second pipe head 3 and a third pipe head 4 in sequence, and the upper end of the second pipe head 3 is processed with The first semicircular protrusion 17, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com