Preparation method of titanium dioxide nano-sheet loaded molybdenum diselenide composite photocatalyst

A technology of titanium dioxide and molybdenum diselenide, applied in physical/chemical process catalysts, special compound water treatment, chemical instruments and methods, etc., can solve obstacles to development and application, low quantum efficiency, high photogenerated electron-hole pair recombination Speed and other issues, to achieve good photocatalytic activity, the effect of catalytic activity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0044] Preparation of molybdenum diselenide composite photocatalyst supported by titanium dioxide nanosheets

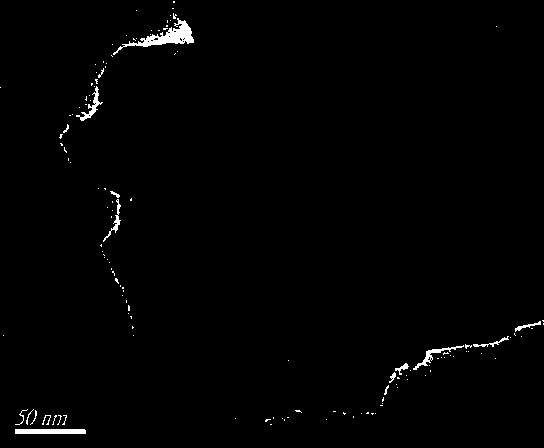

[0045] Weigh 0.8 g of P25 and dissolve it in 50 mL of NaOH (20 mol / L) solution; pour the solution into a reaction kettle and heat at 200°C for 72 hours. After the reaction was completed, the product was soaked in 0.1mol / L HCl solution for 24 hours, washed by centrifugation, and dried; then calcined in a tube furnace at 500°C for 3 hours to obtain TiO 2 Nanosheets.

[0046] Weigh 0.5 gTiO 2 Nanosheets, added to 50 mL of water, stirred evenly; then added 0.017g Na 2 MoO 4 , stir evenly; then add 0.016g of Se powder, stir evenly, add 0.03g NaBH 4 ; Put the mixed solution above into a high-pressure reactor for hydrothermal reaction at a reaction temperature of 200° C. for 48 hours. After the reaction is completed, wash by centrifugation, first wash with ethanol for 4 times, then wash with water for 2 times, the centrifugation speed is 8000rpm, and the time is 7min. ...

Embodiment example 2

[0048] Degradation of Methyl Orange by Molybdenum Diselenide Composite Photocatalyst Supported by Titanium Dioxide Nanosheets under Visible Light Irradiation

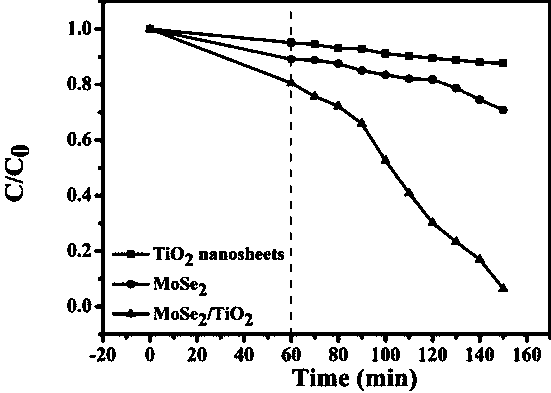

[0049] The titanium dioxide nanosheets supported molybdenum diselenide composite photocatalyst prepared by the method of Example 1 was used for the degradation experiment of methyl orange. The concentration of methyl orange solution is 1×10 -6 mol L -1 Take 50 mg of composite material powder, place in 100 mL of the above-mentioned methyl orange solution, stir in a dark room for 60 minutes, then place the solution in a visible light source where ultraviolet light is filtered out, take 5 mL of methyl orange solution every 10 minutes, The characteristic peak of methyl orange in the solution was measured by UV-Vis spectrophotometer.

[0050]Obtain the degradation curve of visible light degradation of methyl orange by titanium dioxide nanosheet loaded molybdenum diselenide composite photocatalyst according to implementatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com