Food Antioxidant Cellulose Acetate Nanofiber Preservative Film

A technology of cellulose acetate and nanofibers, which is applied in the field of fresh-keeping materials, can solve the problems of solvent residues that cannot be ignored, poor mechanical properties of fibers, and difficult production, etc., and achieve the goal of overcoming mechanical shortages, uniform structure, and safe and environmentally friendly production processes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

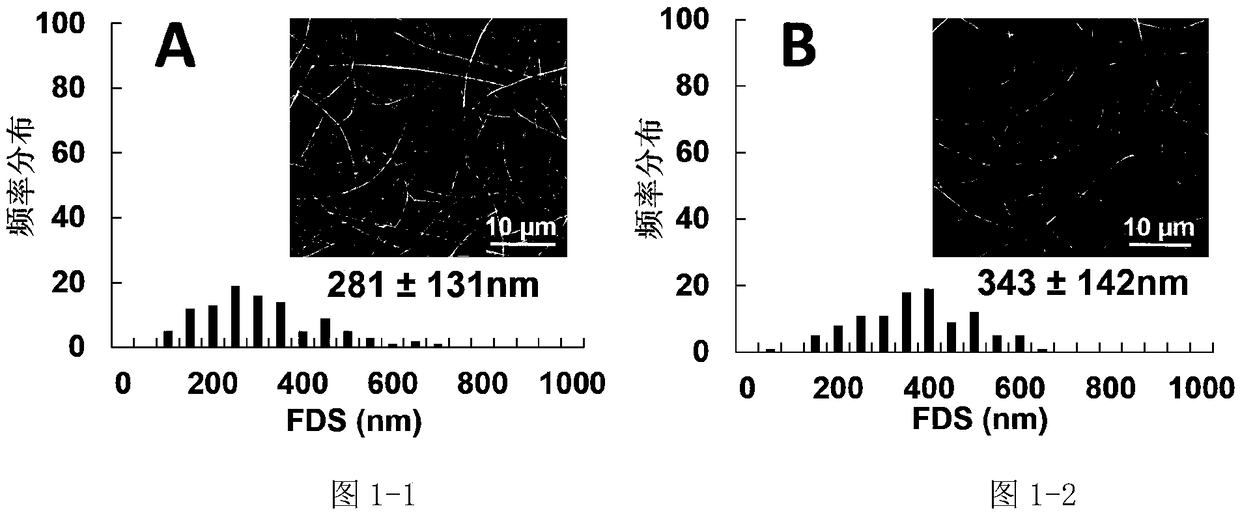

[0034] The invention adopts a novel food-grade glacial acetic acid / water mixed solution as an electrospinning solvent system, utilizes the molecular structure of tannic acid to have both high-efficiency anti-oxidation activity of polyphenols and dual functions of self-assembly, chelation and cross-linking with metal ions, and cellulose acetate As a fiber-forming matrix, use electrospinning technology to build a chelated network structure of tannic acid and iron ions to enhance the mechanical properties of fibers, and use the porous microstructure of nanofibers to efficiently exert the antioxidant activity of tannic acid, creating a one-step method for preparing nanofiber membranes The integrated molding technology of high mechanical propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com