Iron alkoxide oxygen evolution catalyst based on deep eutectic solvent, preparation method and application of electrocatalytic oxygen evolution

A technology of deep eutectic solvent and oxygen catalyst, which is applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of less research and preparation of iron-based oxygen evolution catalysts Technical complexity and other issues, to achieve the effect of excellent oxygen evolution catalytic performance, cheap and easy to obtain raw materials, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of an iron alkoxide oxygen evolution catalyst based on a deep eutectic solvent, comprising steps:

[0033] Choline chloride and glycerol were mixed at a molar ratio of 1:2, and then treated in an oil bath at 80°C for 30 minutes to obtain a colorless transparent solution, which was cooled to room temperature, and the deep eutectic solvent was successfully synthesized.

[0034] Dissolve 121.2mg of ferric nitrate nonahydrate in 3mL of the above-mentioned deep eutectic solvent, then place it in a closed reaction kettle, and conduct an ionothermal reaction at 150°C for 11h; after the reaction is completed, cool to room temperature, centrifuge, wash with absolute ethanol 4 times, and then Put the product in a vacuum oven and dry at room temperature for 12 hours to obtain a yellow-green solid powder.

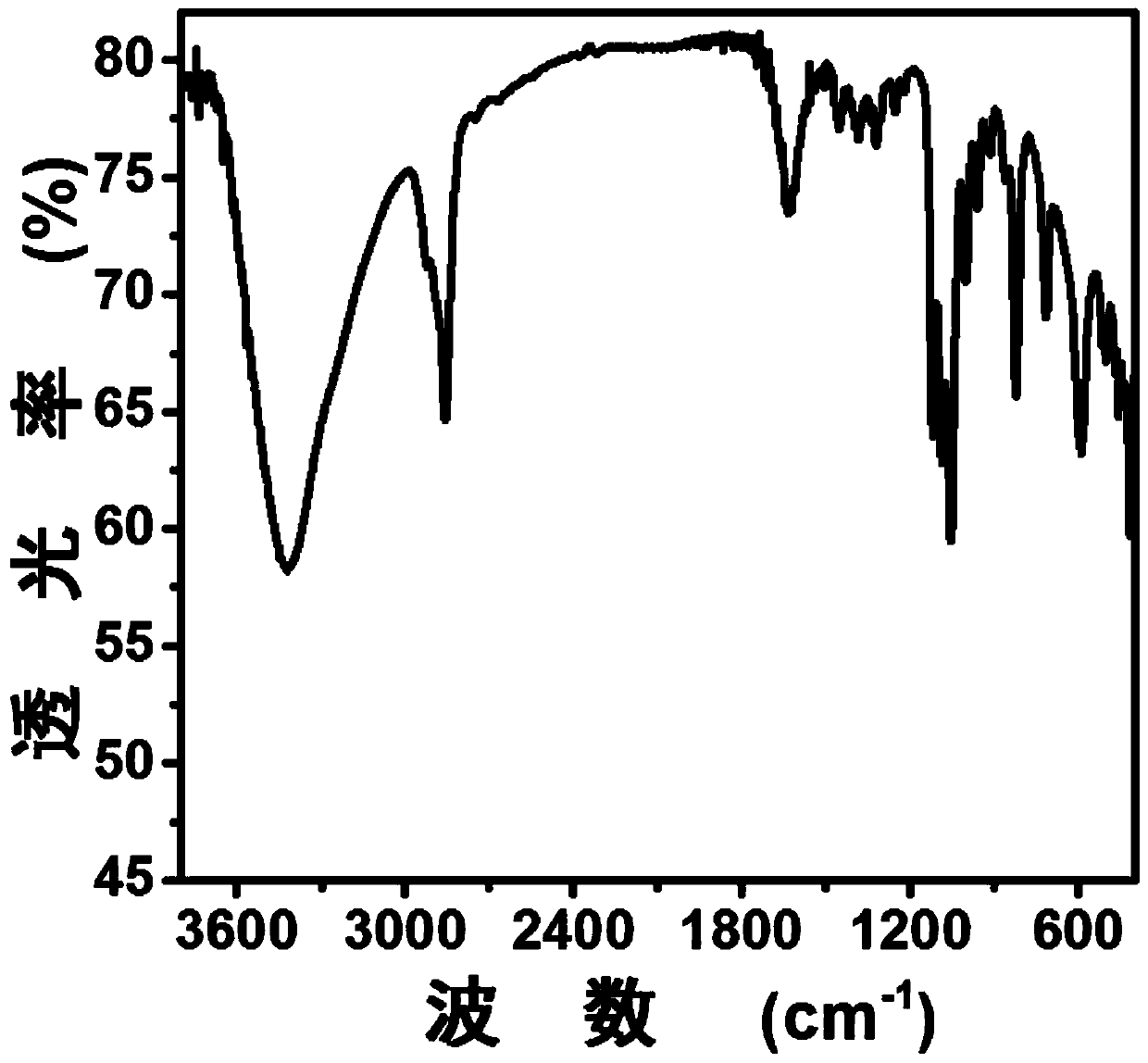

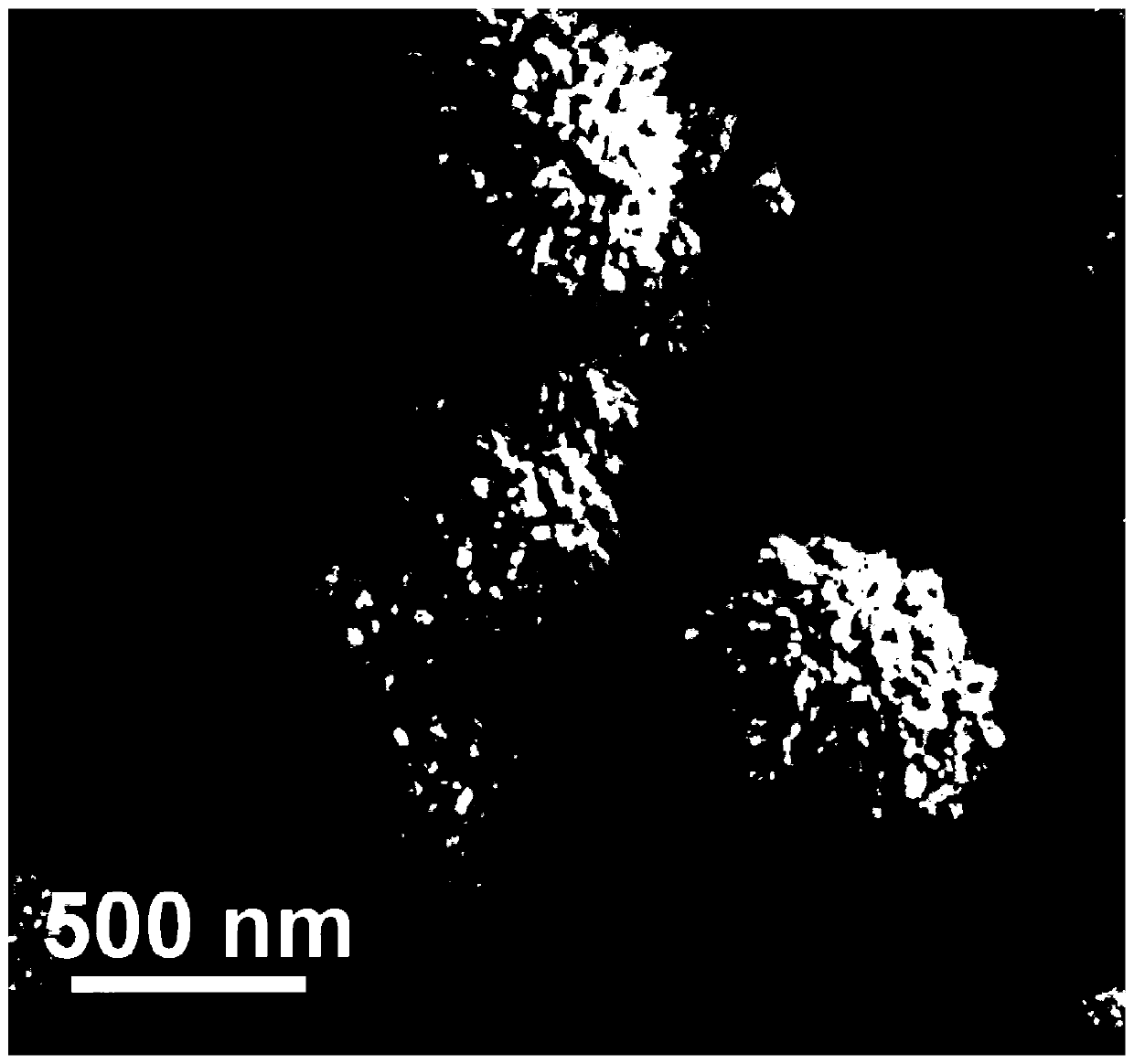

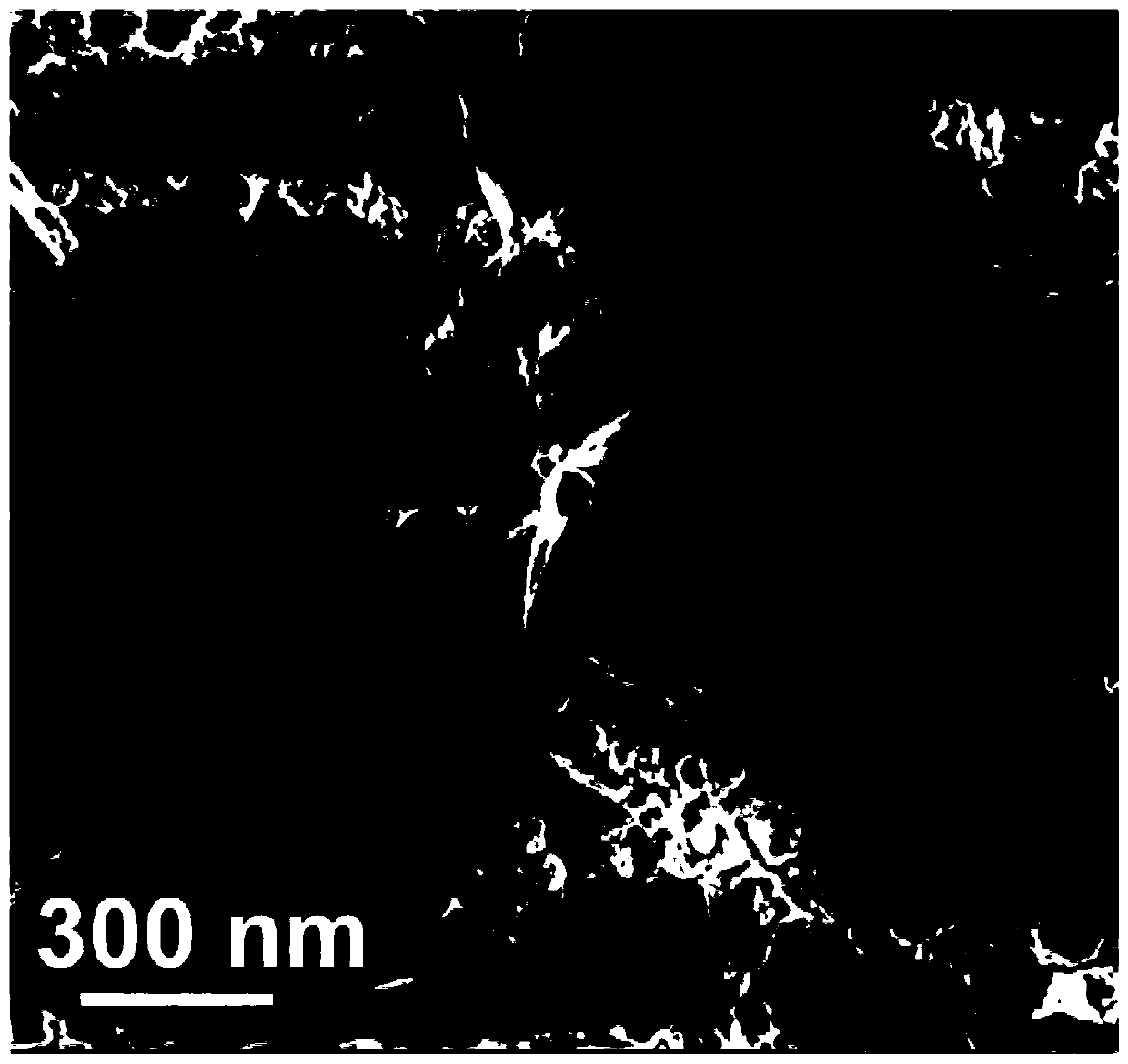

[0035] The infrared spectrogram of the iron alkoxide oxygen evolution catalyst prepared in this embodiment is as follows figure 1 shown. Depend on figure...

Embodiment 2

[0046] A preparation method of an iron alkoxide oxygen evolution catalyst based on a deep eutectic solvent, comprising steps:

[0047] Choline chloride and glycerol were mixed at a molar ratio of 1:2, and then treated in an oil bath at 50°C for 1 h to obtain a colorless transparent solution, which was cooled to room temperature, and the deep eutectic solvent was successfully synthesized.

[0048] Dissolve 105 mg of ferric nitrate nonahydrate in 3 mL of the above-mentioned deep eutectic solvent, then place it in a closed reaction vessel, and conduct an ionothermal reaction at 120°C for 15 hours; after the reaction is completed, cool to room temperature, centrifuge, and wash 4 times with absolute ethanol, and then put The product was placed in a vacuum oven and dried at room temperature for 12 hours to obtain a yellow-green solid powder.

Embodiment 3

[0050] A preparation method of an iron alkoxide oxygen evolution catalyst based on a deep eutectic solvent, comprising steps:

[0051] Choline chloride and glycerin were mixed at a molar ratio of 1:2, and then treated in an oil bath at 120°C for 10 minutes to obtain a colorless transparent solution, which was cooled to room temperature, and the deep eutectic solvent was successfully synthesized.

[0052] Dissolve 135mg of ferric nitrate nonahydrate in 3mL of the above-mentioned deep eutectic solvent, then place it in a closed reaction kettle, and conduct an ionothermal reaction at 180°C for 8h; after the reaction is completed, cool to room temperature, centrifuge, wash with absolute ethanol for 4 times, and then put The product was placed in a vacuum oven and dried at room temperature for 12 hours to obtain a yellow-green solid powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com