Preparation method of hydrophobic strongly acidic carbon material

An acid carbon, hydrophobic technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Weak and other problems, to achieve the effect of simple preparation steps, broad application prospects, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

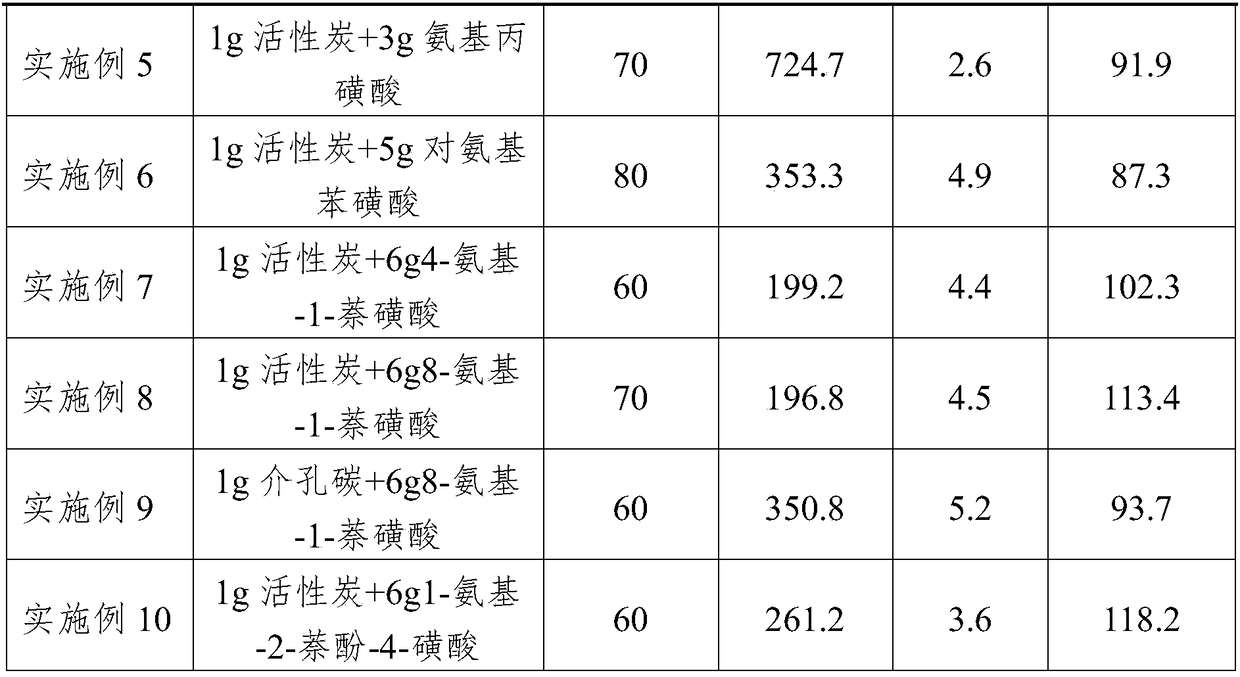

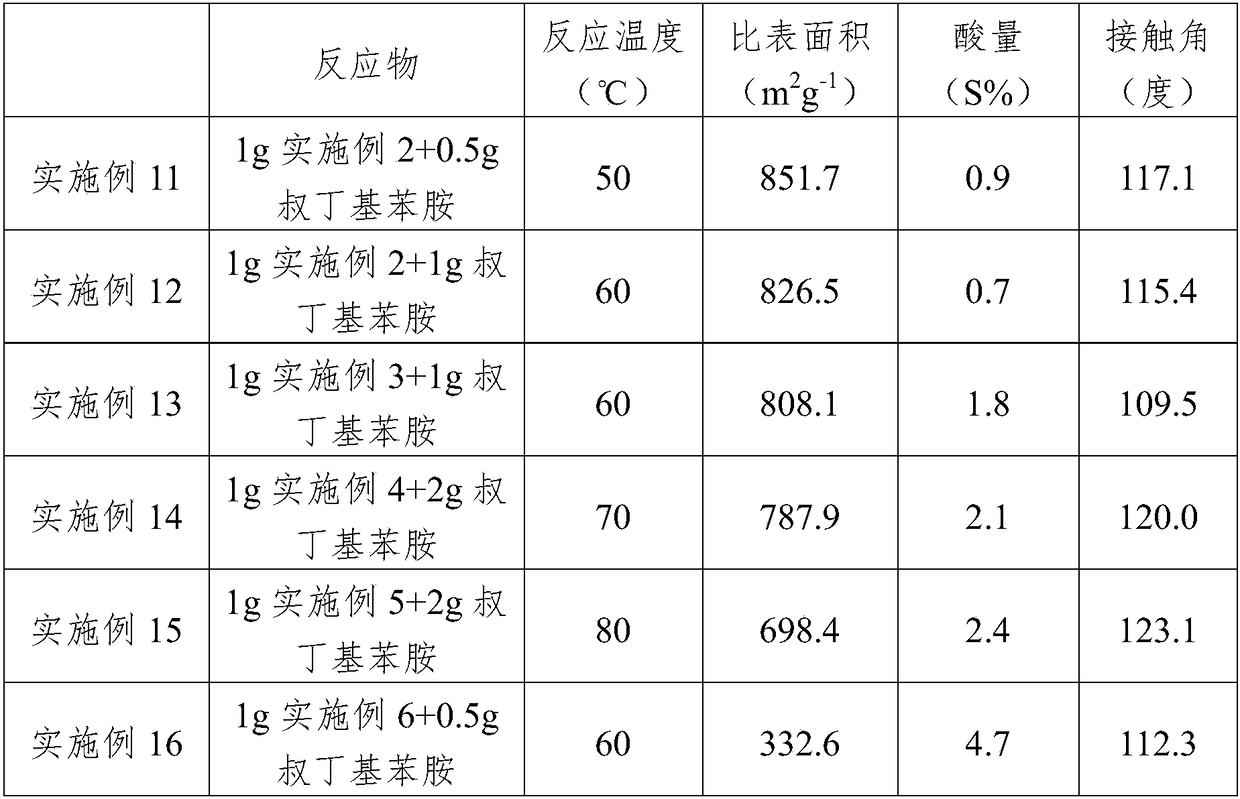

[0017] In the following, the implementation of the present invention is further described with examples in the form of a list. The embodiments are illustrative only, not restrictive.

[0018] Preparation of strongly acidic carbon material: Taking Example 2 in Table 1 as an example: Weigh 0.5g of sulfamic acid, 0.22g of sodium hydroxide and a 250ml three-neck flask, add 100ml of water, heat to 50°C under magnetic stirring, and wait for After the reactant is completely dissolved, measure and adjust to make the pH>7, then add 1g of commercial activated carbon and 0.36g of sodium nitrite in sequence; slowly drop 0.02mol of hydrochloric acid into the reaction solution, stir for 10min, filter and wash, and dry overnight at 80°C . The specific surface area of the sample was measured by the volumetric adsorption instrument, which was 881.4m 2 g -1 , the S% of the sample was measured by an elemental analyzer, which was 1.1%, and the hydrophobicity of the sample was measured by a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com