Method for extracting polyphenol from sea-buckthorn leaves with supercritical CO2 fluid extraction technology

A seabuckthorn leaf and supercritical technology, which is applied in pharmaceutical formulas, medical preparations containing active ingredients, anti-toxins, etc., can solve problems that have not been reported, and achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1. Preparation of Seabuckthorn Leaf Polyphenol Extract

[0034] Mix 100g of 20-mesh seabuckthorn leaf powder with 100ml of 60% ethanol solution (pH 4), soak overnight, put the soaked material in a 300ml extraction kettle, fix the filled extraction kettle in the heating box, and connect the extraction kettle Both ends of the interface, close the intake switch, outlet valve and fine-tuning valve, close the door of the heating box; open the supercritical CO 2For the power supply of the fluid extraction equipment, set the temperature of the extraction kettle to 40°C and the temperature of the fine-tuning valve to 90°C. When the temperature reaches the set value, turn on the inlet switch, adjust the pressure of the extraction kettle to 30MPa, and keep it under this pressure for 10 minutes; open the outlet valve , use the fine-tuning valve to control the gas flow in the recovery bottle, so that the flow meter at the end shows that the flow rate is 2L / min, balance the ...

Embodiment 2

[0036] Effects of ethanol immersion

[0037] The comparison test was carried out by soaking and non-immersing methods, and the yield and polyphenol content were compared for three times, and the results obtained were as follows:

[0038] (yield / polyphenol content)

[0039] It can be seen from the above table that, no matter in terms of the yield of the final product or the content of extracted polyphenols, the method of soaking first and then extracting has made significant progress.

Embodiment 3

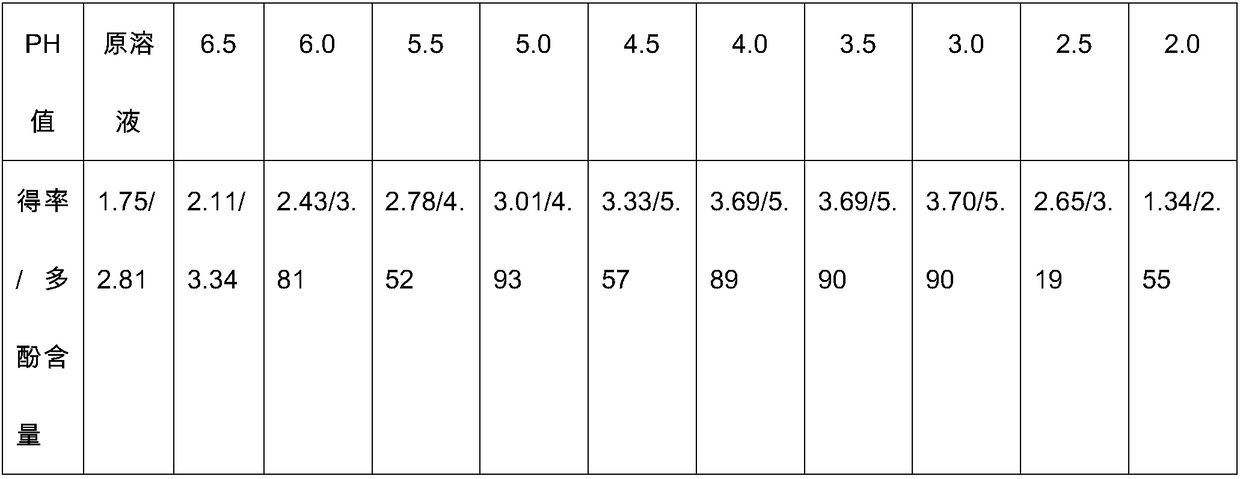

[0041] Effect of pH of ethanol solution

[0042] The inventors used a gradient method to carry out comparative experiments, using the pH values of the original ethanol solution (about 6.9), 6.5, 6.0, 5.5, 5.0, 4.5, 4.0, 3.5, 3.0, 2.5, 2.0, and 1.5. The results obtained are as follows:

[0043]

[0044] From the experimental results, it can be seen that the yield and polyphenol content were greatly improved when the pH gradient of the ethanol solution decreased at first, and basically showed a stable state when the pH was between 3-4, and when the pH decreased again, gradually When entering the strong acid zone, the yield and polyphenol content show a state of rapid decline. The inventor speculates that the reaction of too strong acidity may cause the destruction of the raw material structure, etc., and ultimately affect the product yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com