A kind of antibacterial magnesium alloy

An antibacterial magnesium and alloy technology, applied in the field of magnesium alloy biomedical material preparation, to achieve the effect of avoiding cell or tissue infection, high purity, and uniform composition and tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

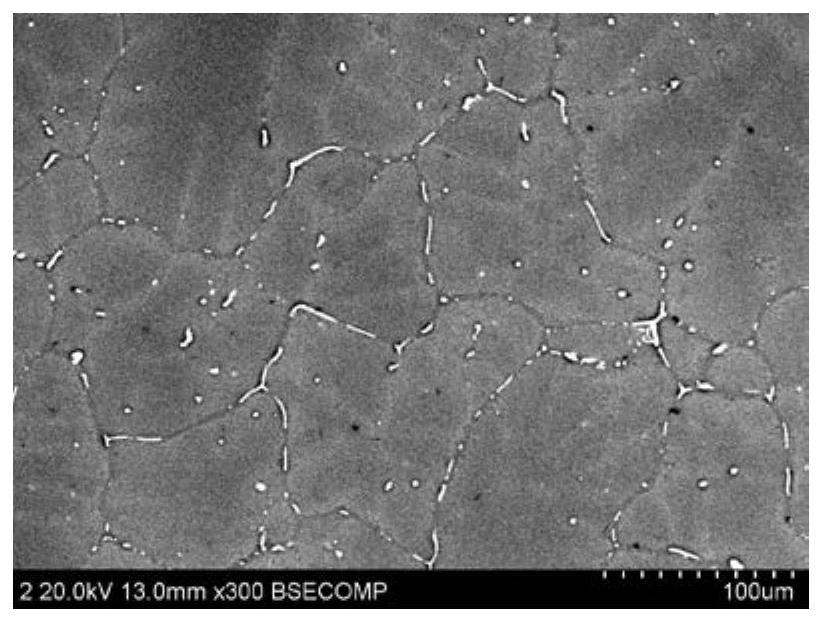

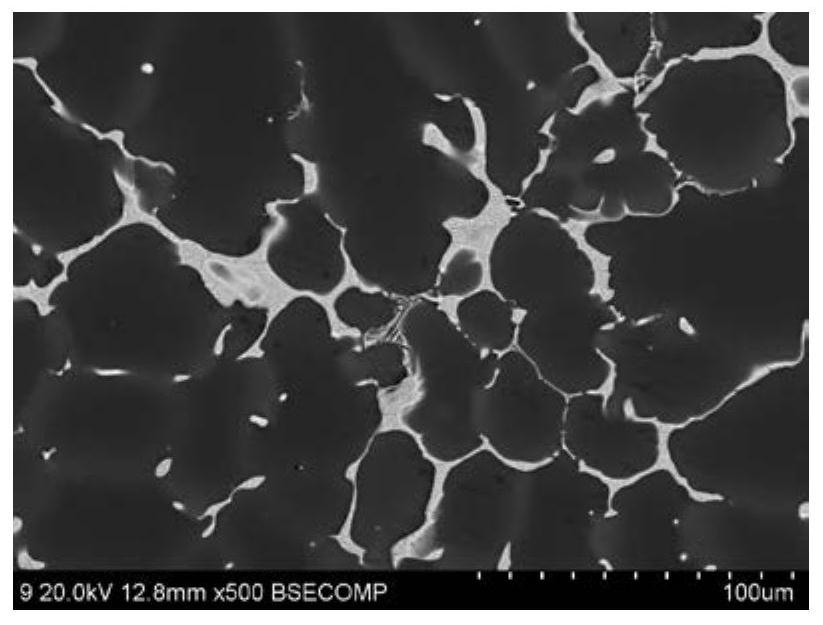

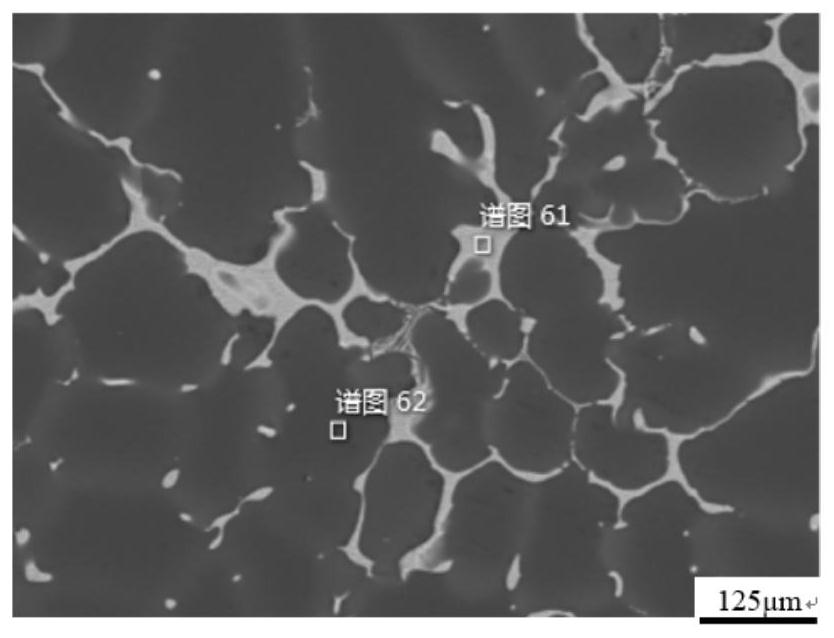

Image

Examples

Embodiment

[0038] The chemical composition of an antibacterial magnesium alloy is: Zn: 5-6wt.%, Zr: 0.3-0.9wt.%, Ag: 1.5-15.0wt.%, Cu: 2.0-4.0wt.%, the balance It is Mg and unavoidable impurities.

[0039] A kind of preparation method of antibacterial magnesium alloy, concrete steps are as follows:

[0040] Step 1, weigh:

[0041] As shown in table 1, take industrial pure magnesium, industrial pure zinc, Mg-Zn-Zr master alloy, Mg-Cu master alloy, Mg-Ag master alloy according to the chemical composition ratio of novel antibacterial magnesium alloy;

[0042] Step 2, preheating, (a), (b) in no order:

[0043] (a) Place the weighed industrial pure magnesium, industrial pure zinc, Mg-Zn-Zr master alloy, Mg-Cu master alloy, and Mg-Ag master alloy in a vacuum drying oven, dry and preheat at 200°C for 20min,

[0044] (b) Place the weighed industrially pure zinc in a vacuum oven, dry and preheat at 120°C for 20 minutes;

[0045] Step 3, smelting:

[0046] Industrial pure magnesium is smelted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com