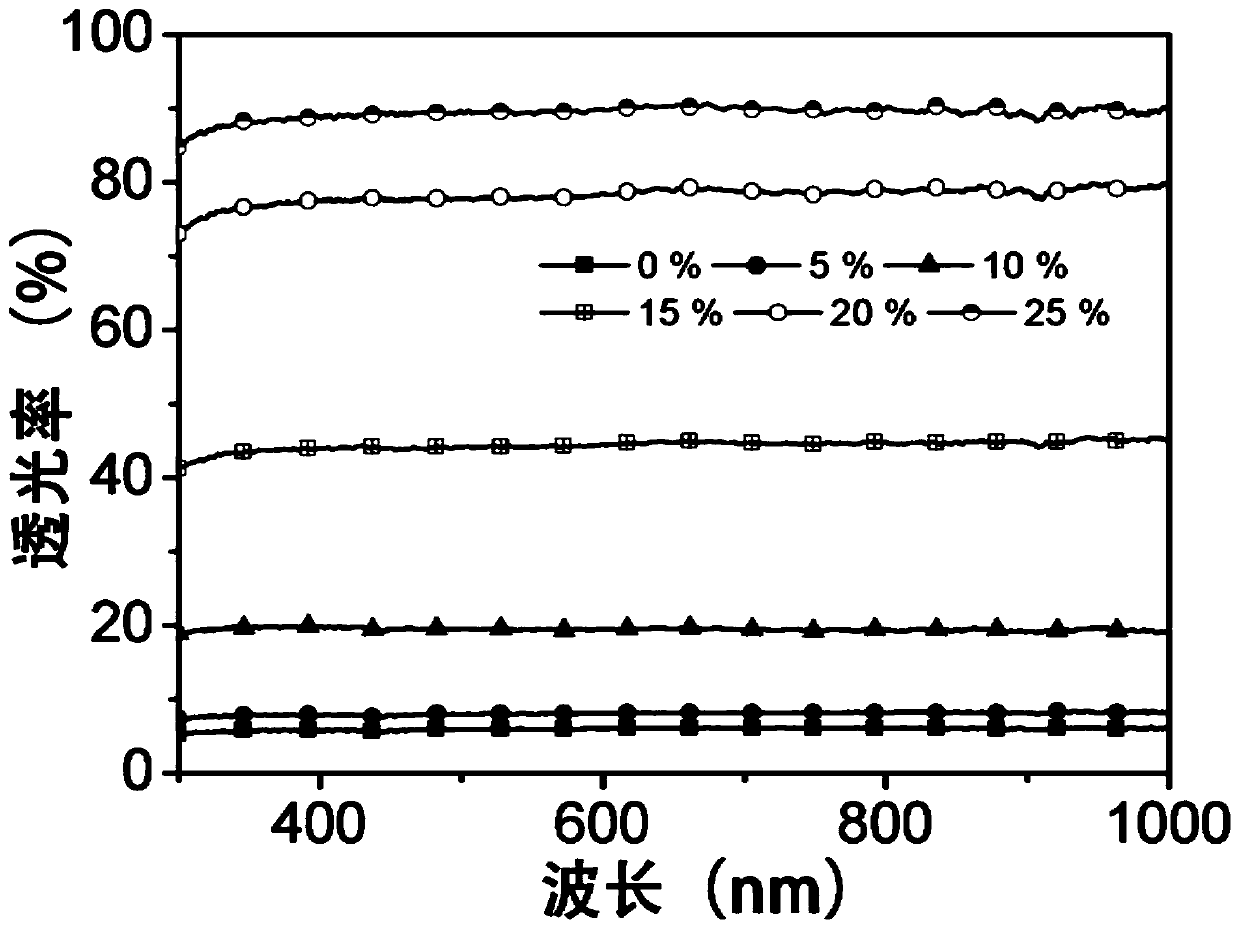

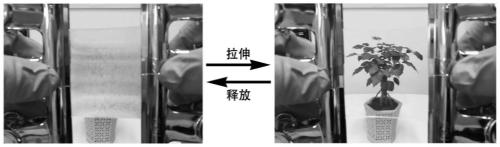

Preparation method of force-responsive surface wrinkles with adjustable light transmittance

A light transmittance and wrinkle technology, applied in the field of smart materials, can solve the problems of increasing the difficulty of operation, unable to control the optical properties of materials, etc., and achieve the effects of wide application range, good reversibility, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing force-responsive PVA / PDMS membrane folds, comprising the following steps:

[0032] (1) Mix the polydimethylsiloxane precursor and the crosslinking agent uniformly at a mass ratio of 10:1, take 9g of the mixed solution and pour it into a 90mm petri dish, remove air bubbles in a vacuum, and heat and cure at 80°C for 2h. Obtain polydimethylsiloxane elastic base;

[0033] Put the above cured polydimethylsiloxane into O 2 Oxidation treatment in the chamber of the plasma etching machine, the working conditions are: the oxygen flow rate is 10ml / min, the radio frequency power is 100W, and the etching time is 20s;

[0034] 3g of 3wt% polyvinyl alcohol (PVA) aqueous solution was drop-coated on the etched polydimethylsiloxane, shaken well and vacuumed to remove air bubbles and dried at 50°C to form a film. The prepared double-layer The film is in a transparent state; placed in a room temperature environment with a relative humidity RH=50% for 1h;

[0035]...

Embodiment 2

[0037] A method for preparing force-responsive PVA / PDMS membrane folds, comprising the following steps:

[0038] (1) Mix the polydimethylsiloxane precursor and the crosslinking agent uniformly at a mass ratio of 10:1, take 9g of the mixed solution and pour it into a 90mm petri dish, remove air bubbles in a vacuum, and heat and cure at 80°C for 2h. Obtain polydimethylsiloxane elastic base; Put the above-mentioned solidified polydimethylsiloxane into O 2 Oxidation treatment in the chamber of the plasma etching machine, the working conditions are: the oxygen flow rate is 10ml / min, the radio frequency power is 100W, and the etching time is 20s;

[0039] 0.09g of 3wt% polyvinyl alcohol aqueous solution was drop-coated on the etched polydimethylsiloxane, shaken well, vacuumed out air bubbles, and then dried at 50°C to form a film. The prepared double-layer film was Transparent state; after being placed in a room temperature environment with RH=70% for 1 hour;

[0040] (2) Cut out ...

Embodiment 3

[0042] A method for preparing force-responsive polyvinylpyrrolidone / PDMS membrane folds, comprising the following steps:

[0043] (1) Evenly mix the polydimethylsiloxane precursor and the crosslinking agent at a mass ratio of 10:1, take 4.4g of the mixed solution and pour it into a 60mm petri dish, remove air bubbles in a vacuum and heat and cure at 80°C for 2h , to obtain polydimethylsiloxane elastic base; put the cured polydimethylsiloxane into O 2 Oxidation treatment in the chamber of the plasma etching machine, the working conditions are: the oxygen flow rate is 10ml / min, the radio frequency power is 100W, and the etching time is 20s;

[0044] Put 0.1g of polyvinyl chloride powder solvent in 5ml of dimethylacetamide solution, take 1g of the mixed solution and drop it on the etched polydimethylsiloxane, shake it well, remove air bubbles in vacuum, and dry at 50°C Film formation, the prepared double-layer film is in a transparent state, after being placed in a room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com