A kind of preparation method of cover plate and cover plate

A cover plate and glass substrate technology, which is applied to the preparation method of the cover plate and the field of the cover plate, can solve the problems of high processing difficulty, etching selection of small microstructure aspect ratio, and poor effect of microstructure processing, etc., to achieve practical mass production Strong resistance, good anti-anti-reflection effect, and large aspect ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

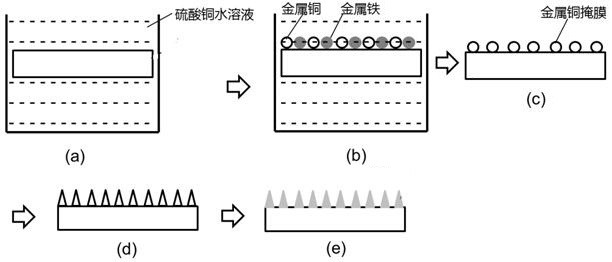

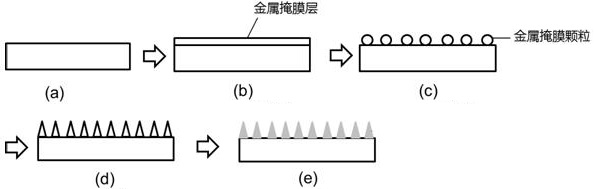

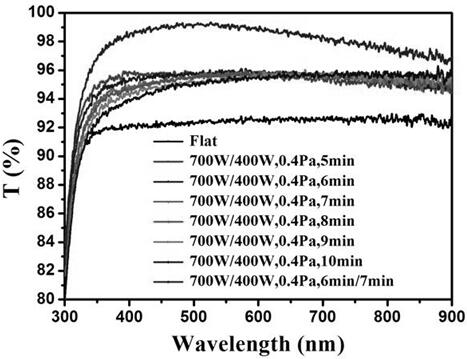

[0031] Since the preparation of moth-eye structures on the surface of glass substrates (such as convex cone-shaped anti-reflection microstructures with gradient refractive index) can achieve better anti-reflection effects, moth-eye structures are usually prepared on the cover plate to reduce the reflectivity of the surface of mobile phones . Such as figure 1 As shown, in the preparation method of the existing cover plate, specifically include the steps: first provide a glass substrate (such as figure 1 shown in a), followed by preparing a layer of transparent silicone soft film layer with the same or similar refractive index as the glass on the surface of the cleaned glass substrate (such as figure 1 shown in b), and then spin-coat a layer of nanoimprint adhesiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com