Jade carving processing platform

A processing platform, jade carving technology, applied in the direction of processing models, decorative arts, etc., can solve the problems of affecting the engraving machine's walking route, reducing the temperature of jade, and reducing the engraving accuracy, so as to improve engraving accuracy, reduce damage, and have a wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

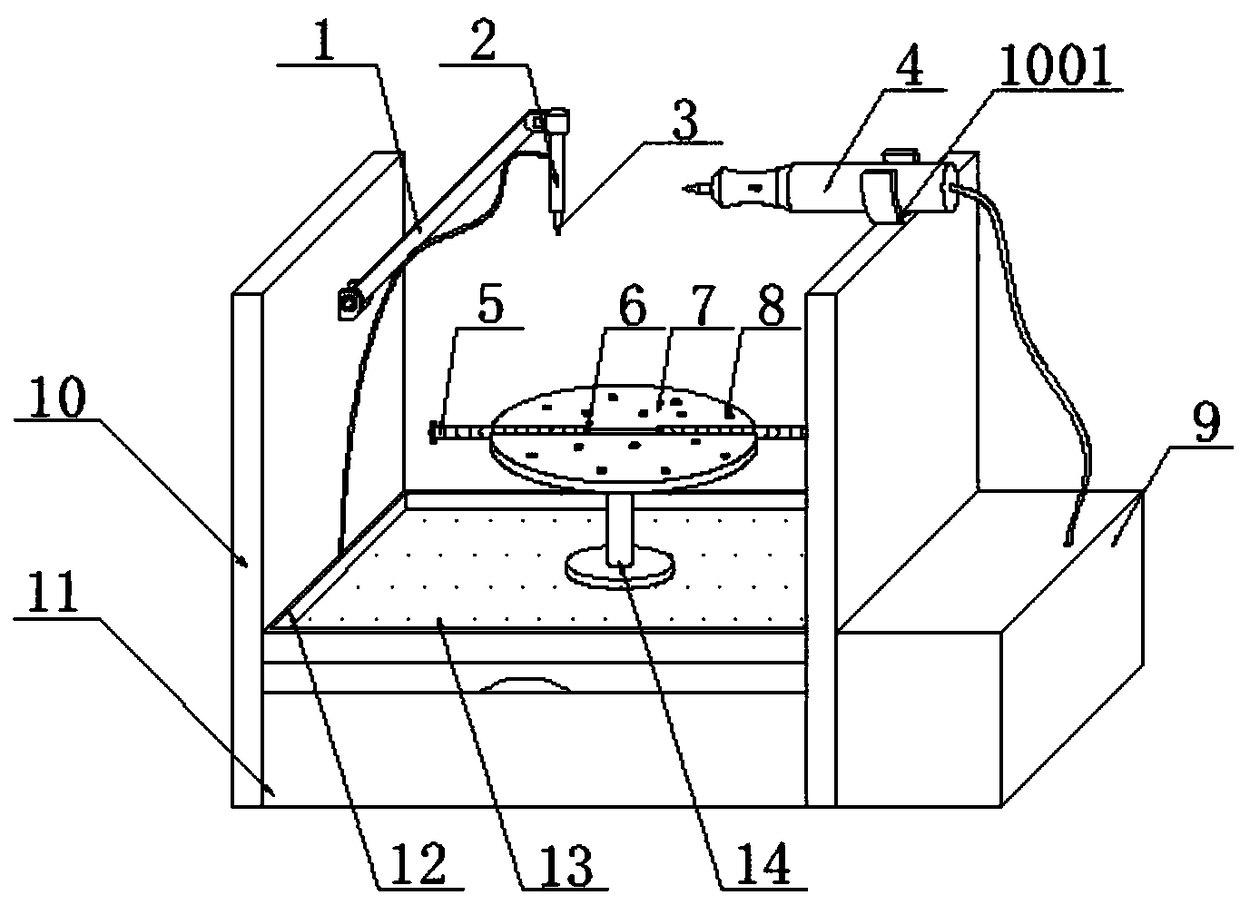

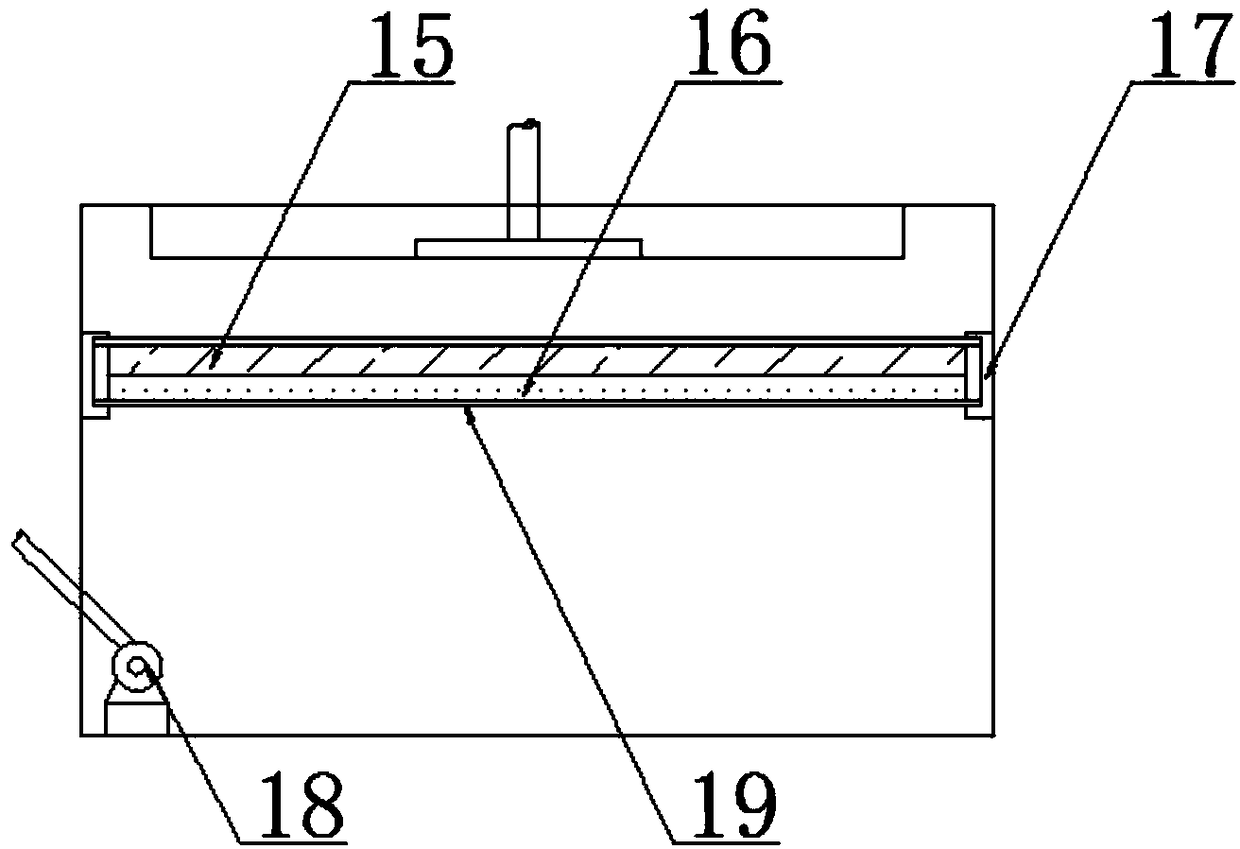

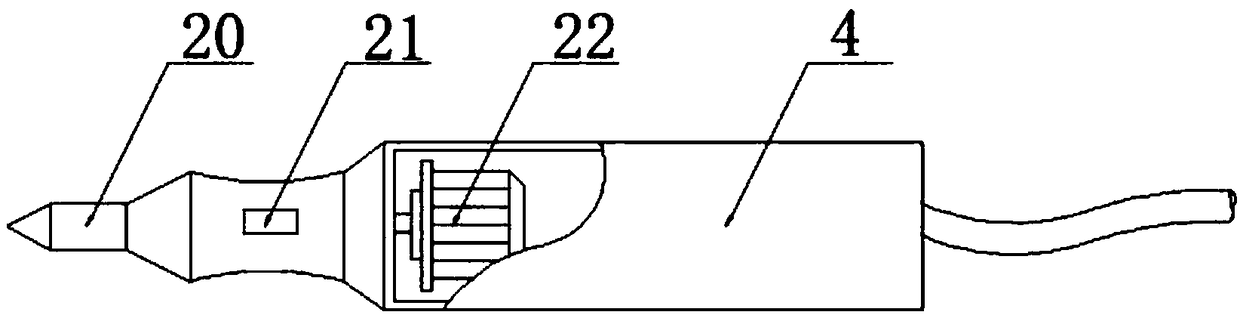

[0020] Such as Figure 1 to Figure 3 As shown, a jade carving processing platform according to the present invention includes a water tank 11, a water pump 18 is installed inside the water tank 11, and two left and right symmetrical chutes 17 are welded on the upper part of the water tank 11; The chute 17 is slidably connected to the outer frame 19, and the inside of the outer frame 19 is fixed with a non-woven filter layer 15; Pull out, be convenient to the cleaning of non-woven fabric filter layer 15 and filter paper sheet 16, the top of described water tank 11 is provided with groove 12, and the inside of described groove 12 is provided with filter screen 13, on the filter screen 13 The mesh is formed by stamping, and there is an upward flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com