A kind of manufacturing method of piled abrasive emery cloth

A technology of accumulating abrasives and manufacturing technology, which is applied in the direction of manufacturing tools, abrasives, metal processing equipment, etc., can solve the problems of low hardness, short grinding life, poor anti-blocking effect, etc., achieve good stiffness and increase grinding Long life, good chip removal and anti-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

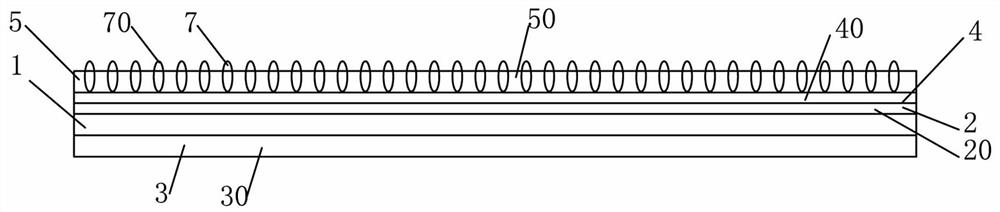

[0031] Embodiment one, such as figure 1 As shown, a manufacturing method of accumulated abrasive emery cloth includes the following steps: Step 1: gray cloth production: the gray cloth is produced by using advanced ring weaving equipment.

[0032] Step 2: Obtain the original cloth: Singeing, washing, drying, and shaping the gray cloth to obtain the cloth base, so as to ensure the flatness and tensile strength of the cloth base 1.

[0033] Step 3 Stretching and setting: Perform high-temperature stretching and setting treatment on the cloth base 1 obtained in step 2, stretch the cloth base 1 in all directions, so that the cloth base 1 is fully stressed in all directions, and the stretching temperature reaches 200°C at the same time Next, the polyester obtained from the cloth base 1 is recrystallized, so as to ensure that the cloth base 1 is not stretched, so that the resilience of the cloth base 1 is weakened.

[0034] Step 4 Backfill: Apply backfill adhesive 30 to the back of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com