Polyester cloth high-temperature setting device

A technology of high-temperature shaping and polyester cloth, applied in the field of polyester cloth, can solve problems such as trouble and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

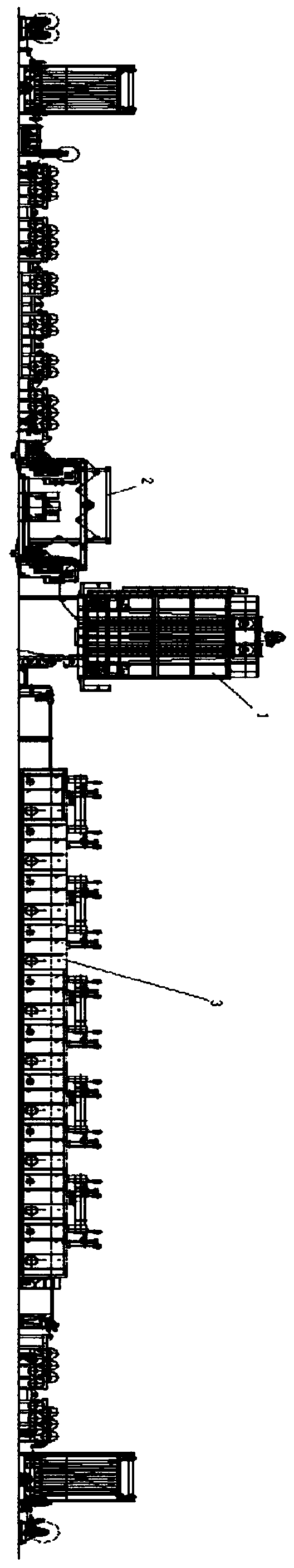

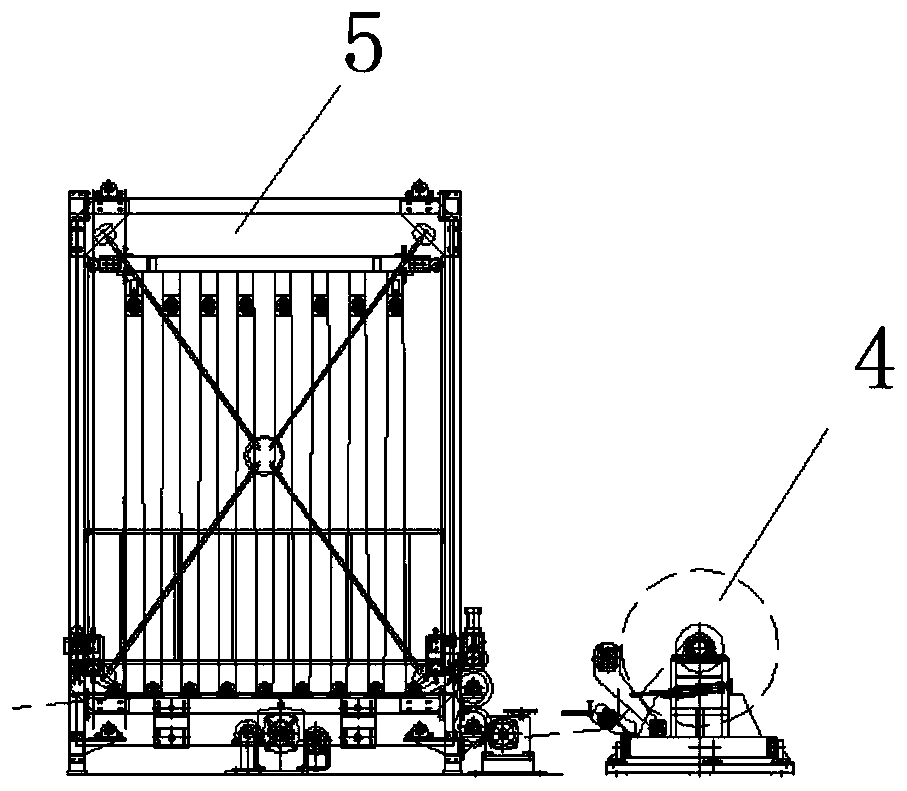

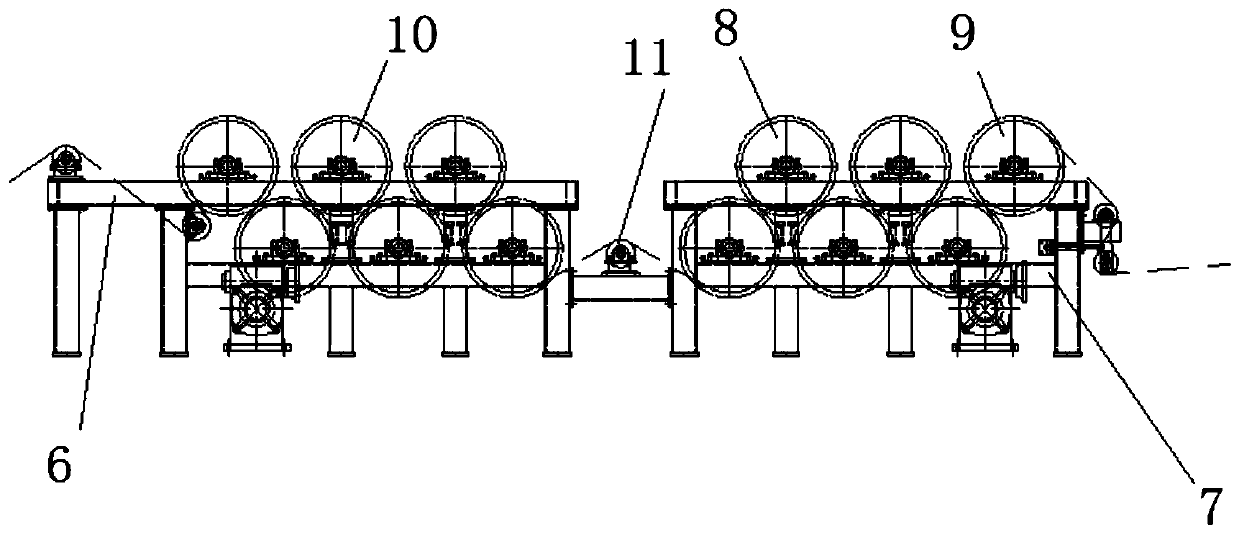

[0019] Such as figure 1 , figure 2 , Figure 6 and Figure 7 The high-temperature sizing device for polyester cloth shown is characterized in that it includes two heating and cooling components, a stretching component, a dipping component 2, a vertical oven 1, a tenter drying room 3, an unwinding component and a winding component, The unwinding assembly, stretching assembly, impregnating assembly 2, vertical oven 1, tenter drying room 3 and winding assembly are placed in sequence from left to right, between the unwinding assembly and stretching assembly and the drawing A heating and cooling assembly is arranged between the drying room 3 and the winding assembly. The unwinding assembly is composed of an unwinding machine 21 and a first cloth storage mechanism 22. The winding assembly is composed of a winding machine 4 and the second cloth storage mechanism 5, and the first cloth storage mechanism 22 and the second cloth storage mechanism 5 are all composed of the first brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com