Preparation method of silicon negative electrode material of lithium ion battery

A lithium-ion battery, silicon anode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems affecting the performance of lithium-ion batteries, affecting electron and ion transport, etc., to achieve strong bonding, good controllability, Enhance the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

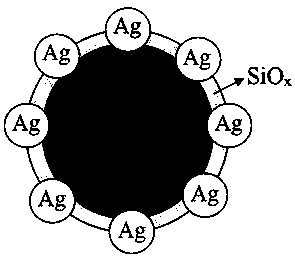

Image

Examples

Embodiment 1

[0021] The method for preparing a silicon negative electrode material of a lithium ion battery described in this embodiment specifically includes the following steps.

[0022] (1) Use acetone, hydrofluoric acid and ultrapure water to clean the silicon powder raw materials in sequence.

[0023] (2) Then put the cleaned silicon powder in 0.1 M AgNO 3 Stirring in a mixed solution with 1 M HF, the treatment time is 3min, and the solution temperature is 25℃.

[0024] (3) Finally, put the silicon powder after the above treatment in pure water for oxidation treatment, the water temperature is 90℃, and the treatment time is 60min. After the oxidation, the silicon powder is suction filtered and dried.

Embodiment 2

[0026] The method for preparing a silicon negative electrode material of a lithium ion battery described in this embodiment specifically includes the following steps.

[0027] (1) Use acetone, hydrofluoric acid and ultrapure water to clean the silicon powder raw materials in sequence.

[0028] (2) Then put the cleaned silicon powder in 0.05 M AgNO 3 It is stirred in the mixed solution of 2 M HF, the treatment time is 5 min, and the solution temperature is 40°C.

[0029] (3) Finally, put the silicon powder treated above into 1 M H 2 SO 4 The oxidation treatment is carried out in the aqueous solution, the solution temperature is 40°C, and the treatment time is 30 minutes. After the oxidation is completed, the silicon powder is suction filtered and dried.

Embodiment 3

[0031] The method for preparing a silicon negative electrode material of a lithium ion battery described in this embodiment specifically includes the following steps.

[0032] (1) Use acetone, hydrofluoric acid and ultrapure water to clean the silicon powder raw materials in sequence.

[0033] (2) Then put the cleaned silicon powder in 0.2 M AgNO 3 And 4 M HF mixed solution for stirring treatment, the treatment time is 3min, the solution temperature is 30℃.

[0034] (3) Finally, put the silicon powder after the above treatment in a vacuum furnace for oxidation treatment, the atmosphere in the furnace is Ar / O 2 Mixed gas, where Ar: O 2 = 95:5 (wt.%), the treatment temperature is 800℃, and the treatment time is 30min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com