One-way heat transfer structure based on material thermal expansion difference and application method

A technology of thermal expansion and thermal expansion rate, which is applied in the field of one-way heat transfer devices, can solve the problems of thickened permafrost layers, inappropriateness, and high cost of thermal diodes, and achieve the effects of cost reduction, simple structure, and increased application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

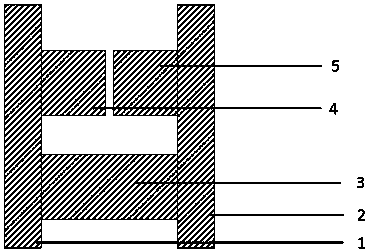

[0028] The structure includes a partition 1, a partition 2, a support column 3 and a heat transfer column. The heat transfer column is composed of a heat transfer half column 4, a heat transfer half column 5 and the gap between the two half columns; the heat transfer half column 4, 5 and the support column 3 are placed between the two partitions, and the support column 3 mechanically connects and fixes the partitions 1 and 2.

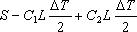

[0029] The theoretical model of the ideal one-way heat transfer structure is given below. Assuming that the length of the heat transfer half column is L, the thermal expansion coefficients of the left and right heat transfer half columns are respectively C L and C R , the length of the support column is 2L, and the thermal expansion rate is C, where C L >C>C R , the reference temperature is T 0 , the gap between the left and right heat transfer semi-columns is S at the reference temperature. Assuming that the thermal expansion rate of the support c...

Embodiment 2

[0041] The structure includes a partition 1, a partition 2, a support column 3 and a heat transfer column. The heat transfer column is composed of a heat transfer half column 4, a heat transfer half column 5 and the gap between the two half columns; the heat transfer half column 4, 5 and the support column 3 are placed between the two partitions, and the support column 3 mechanically connects and fixes the partitions 1 and 2.

[0042] The theoretical model of the ideal one-way heat transfer structure is given below. Assuming that the length of the heat transfer half column is L, the thermal expansion coefficients of the left and right heat transfer half columns are respectively C L and C R , the length of the support column is 2L, and the thermal expansion rate is C, where C L >C>C R , the reference temperature is T 0 , the gap between the left and right heat transfer semi-columns is S at the reference temperature. Assuming that the thermal expansion rate of the support c...

Embodiment 3

[0054] The structure includes a partition 1, a partition 2, a support column 3 and a heat transfer column. The heat transfer column is composed of a heat transfer half column 4, a heat transfer half column 5 and the gap between the two half columns; the heat transfer half column 4, 5 and the support column 3 are placed between the two partitions, and the support column 3 mechanically connects and fixes the partitions 1 and 2.

[0055] The theoretical model of the ideal one-way heat transfer structure is given below. Assuming that the length of the heat transfer half column is L, the thermal expansion coefficients of the left and right heat transfer half columns are respectively C L and C R , the length of the support column is 2L, and the thermal expansion rate is C, where C L >C>C R , the reference temperature is T 0 , the gap between the left and right heat transfer semi-columns is S at the reference temperature. Assuming that the thermal expansion rate of the support c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com