Low-dielectric-constant halogen-free resin composition and low-flowability prepreg with same

A resin composition and low-dielectric technology, applied in the field of halogen-free low-dielectric resin composition and low-flow prepreg, can solve the problems of increased overall viscosity of resin glue, poor wettability of reinforcing materials, etc. The effect of good bonding, excellent flame retardant performance and good processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

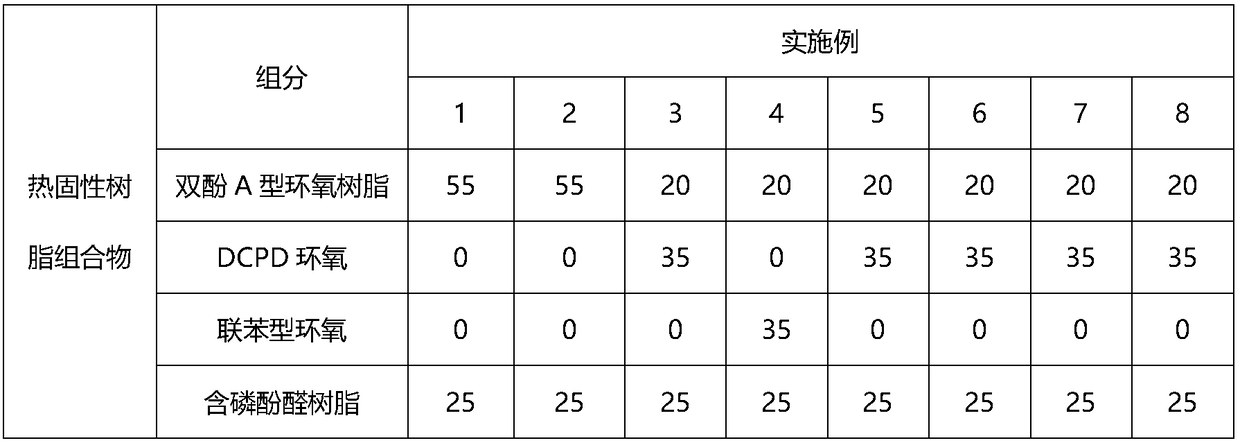

[0028] The following specific examples are further descriptions of the methods and technical solutions provided by the present invention, but should not be construed as limiting the present invention. The instruments, equipment and methods used in the present invention are commonly used instruments, equipment and methods in the art unless otherwise specified.

[0029] The types and sources of the raw materials used to prepare the halogen-free low-dielectric resin composition in the examples of the present invention are as follows:

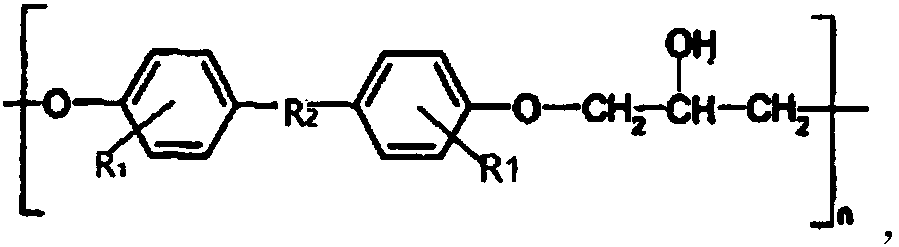

[0030] Bisphenol A epoxy resin, manufacturer: Nanya Epoxy, NPEL-128

[0031] Phosphorus-containing phenolic resin, manufacturer: Dow, XZ92741

[0032] DCPD epoxy, manufacturer: Changchun, Taiwan, DNE260

[0033] Biphenyl type epoxy, manufacturer: SHIN-A, SE-70H

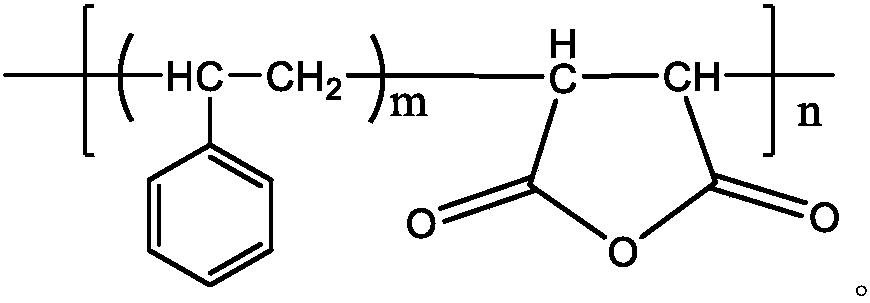

[0034] Curing agent EF-30, manufacturer: Cray Valley, styrene-maleic anhydride copolymer (St:MA=3:1)

[0035] Curing agent EF-40, manufacturer: Cray Valley, styrene-maleic anhydride co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com