PVC (polyvinyl chloride) heat stabilizer based on polyol ester metal complex

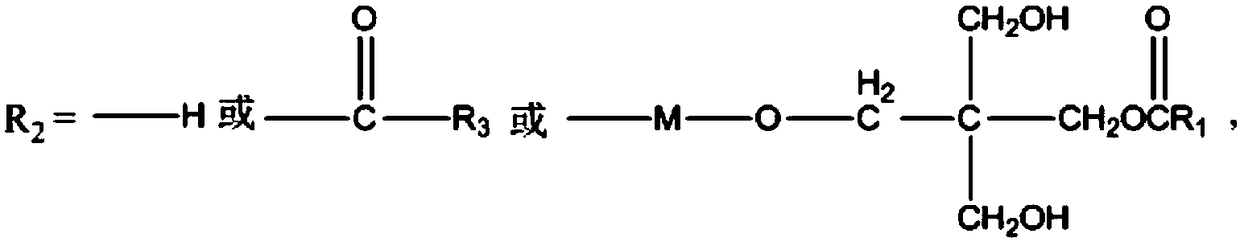

A technology of metal complexes and polyol esters, applied in the field of PVC heat stabilizers based on polyol ester metal complexes, can solve the problems of compatibility between heat stabilizers and PVC substrates, and achieve good thermal stability and Lubrication performance, ease of production and use, improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Calculated in parts by mass, weigh 100 parts of PVC, add 4 parts of magnesium-based pentaerythritol ester, 2.4 parts of calcium stearate, 1 part of dibenzoylmethane, 4 parts of calcium carbonate, and 4 parts of DOP. After stirring and mixing these raw materials, refer to the national standard GB / T2917.1-2002, use the Congo red test commonly used in the PVC product industry to characterize the static thermal stability, and use the torque rheology test to characterize the dynamic thermal stability and processing performance. Performance, during the test of dynamic thermal stability performance, the temperature of the material reaches 190°C-195°C, and the test results are shown in Table 1 and Table 2.

[0028] The magnesium-based pentaerythritol ester is prepared by a method: Weigh the reactant raw materials with the ratio of dipentaerythritol, palmitic acid and stearic acid as 1:1.1:1.1, add it into a three-necked flask and mix, and stir while heating , after heating up t...

Embodiment 2

[0030] Calculated in parts by mass, weigh 100 parts of PVC, add 4 parts of zinc-based pentaerythritol ester, 2.4 parts of calcium stearate, 1 part of hydrotalcite, 4 parts of calcium carbonate, and 4 parts of DOP. After stirring and mixing these raw materials, refer to the national standard GB / T2917.1-2002, use the Congo red test commonly used in the PVC product industry to characterize the static thermal stability, and use the torque rheology test to characterize the dynamic thermal stability and processing performance. Performance, during the test of dynamic thermal stability performance, the temperature of the material reaches 190°C-195°C, and the test results are shown in Table 1 and Table 2.

[0031] The zinc-based pentaerythritol ester is prepared by a method: Weigh the reactant with a ratio of dipentaerythritol and lauric acid of 1:1.1, put it into a three-necked flask and mix it, stir while heating, and wait until the temperature rises to 130°C Finally, add p-toluenesu...

Embodiment 3

[0033]Calculated in parts by mass, weigh 100 parts of PVC, add 4 parts of barium pentaerythritol ester, 2.4 parts of calcium stearate, 1 part of epoxidized soybean oil, 4 parts of calcium carbonate, and 4 parts of DOP. After stirring and mixing these raw materials, refer to the national standard GB / T2917.1-2002, use the Congo red test commonly used in the PVC product industry to characterize the static thermal stability, and use the torque rheology test to characterize the dynamic thermal stability and processing performance. Performance, during the test of dynamic thermal stability performance, the temperature of the material reaches 190°C-195°C, and the test results are shown in Table 1 and Table 2.

[0034] The barium-based pentaerythritol ester is prepared by a method: Weigh the reactant whose molar ratio of dipentaerythritol and myristic acid is 1:2.1, put it into a three-necked flask and mix it, stir while heating, and wait until the temperature rises to After 140°C, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com