Method for efficiently releasing potassium from acid-leached illite by aid of microwaves

A microwave-assisted, illite technology, applied in the field of comprehensive utilization of illite resources, can solve the problems of high energy consumption and long cycle, and achieve the effect of wide source and shortened temperature and time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for efficiently releasing potassium from microwave-assisted acid leaching illite, comprising the following steps:

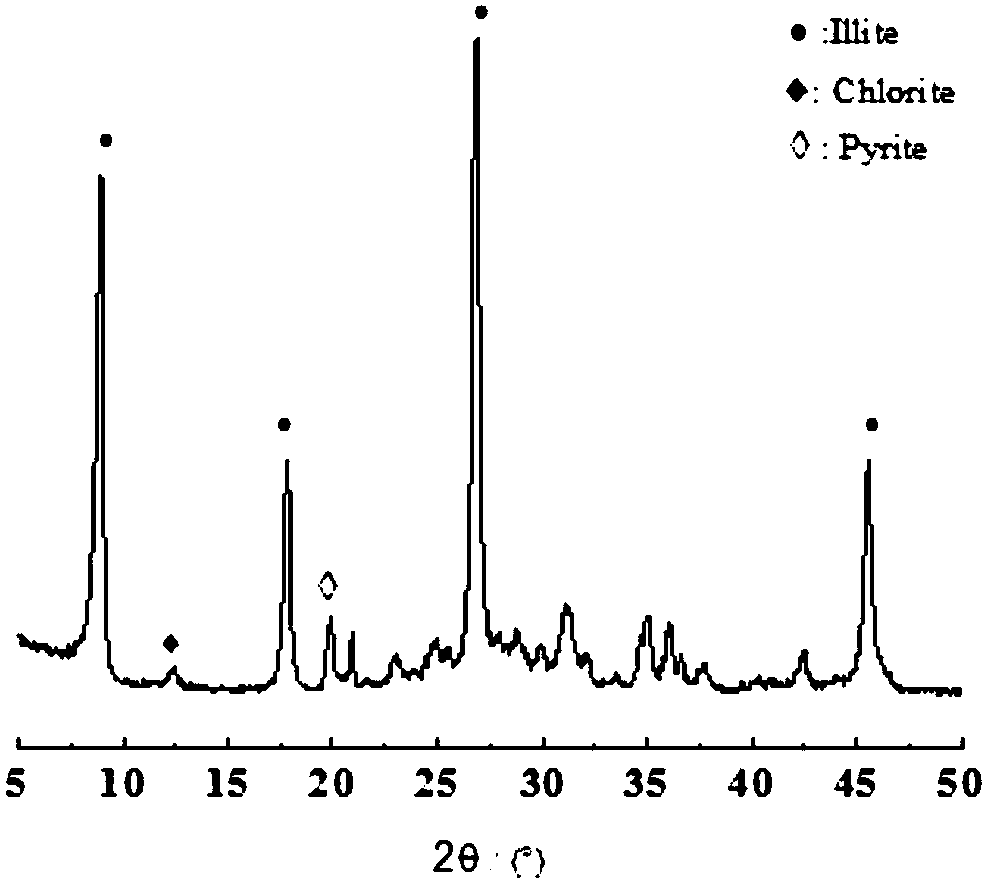

[0024] (1), after the illite raw ore is flotation-removed, it is ground to powder;

[0025] (2), 5moL / L hydrochloric acid and illite powder are uniformly mixed in a certain proportion, wherein, the solid-liquid ratio of illite and hydrochloric acid is 1:4.5mL / g;

[0026] (3), put the mixed material into a microwave hydrothermal digestion instrument, and irradiate it for 30 minutes at a system temperature of 170°C;

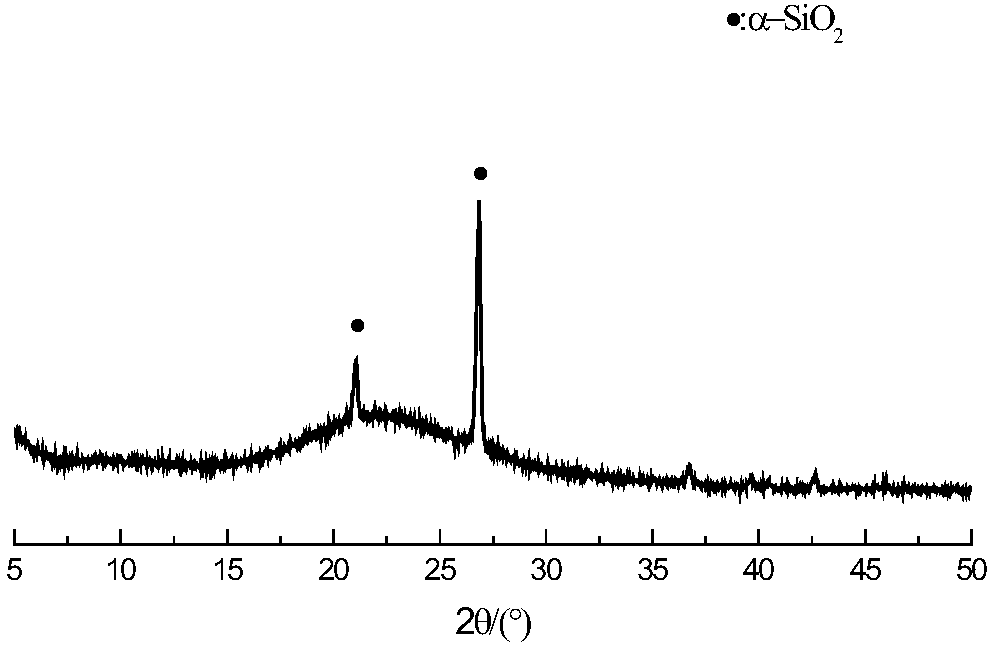

[0027] (4), take out the reacted material, suction filter to neutrality, test the silicon dioxide component and potassium extraction rate in the residue, the silicon dioxide purity is 95.4% (the iron content is 0.2%), and the illite potassium release rate reached 92.1%;

[0028] (5), after the filtrate obtained in the step (4) is evaporated and concentrated, ethanol is added, and the potassium chloride product with a purity greater t...

Embodiment 2

[0030] A method for efficiently releasing potassium from microwave-assisted acid leaching illite, comprising the following steps:

[0031] (1), after the illite raw ore is flotation-removed, it is ground to powder;

[0032] (2), uniformly mix 3moL / L sulfuric acid and illite powder in a certain proportion, wherein, the solid-liquid ratio of illite and sulfuric acid is 1:10mL / g;

[0033] (3), put the mixed material into a microwave hydrothermal digestion apparatus, and irradiate it for 15 minutes at a system temperature of 160°C;

[0034] (4), take out the reacted material, suction filter to neutrality, test the silicon dioxide component and potassium extraction rate in the residue, the silicon dioxide purity in the solid is 94.1% (the iron content is 0.2%), and the illite released Potassium rate reaches 90.7%;

[0035] (5), after the filtrate gained in the step (4) is evaporated and concentrated, ethanol is added, and the potassium chloride product with a purity of more than ...

Embodiment 3

[0037] A method for efficiently releasing potassium from microwave-assisted acid leaching illite, comprising the following steps:

[0038] (1), after the illite raw ore is flotation-removed, it is ground to powder;

[0039] (2) Uniformly mix 10moL / L nitric acid and illite powder in a certain proportion, wherein the solid-to-liquid ratio of illite and salt nitric acid is 1:1mL / g;

[0040] (3), put the mixed material into a microwave hydrothermal digestion apparatus, and irradiate for 5 minutes at a system temperature of 190°C;

[0041] (4), take out the reacted material, suction filter to neutrality, test the silicon dioxide component and potassium extraction rate in the residue, the silicon dioxide purity in the solid is 95.2% (the iron content is 0.2%), and the illite released Potassium rate reached 91.4%;

[0042] (5), after the filtrate gained in the step (4) is evaporated and concentrated, ethanol is added, and the potassium chloride product with a purity of more than 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com