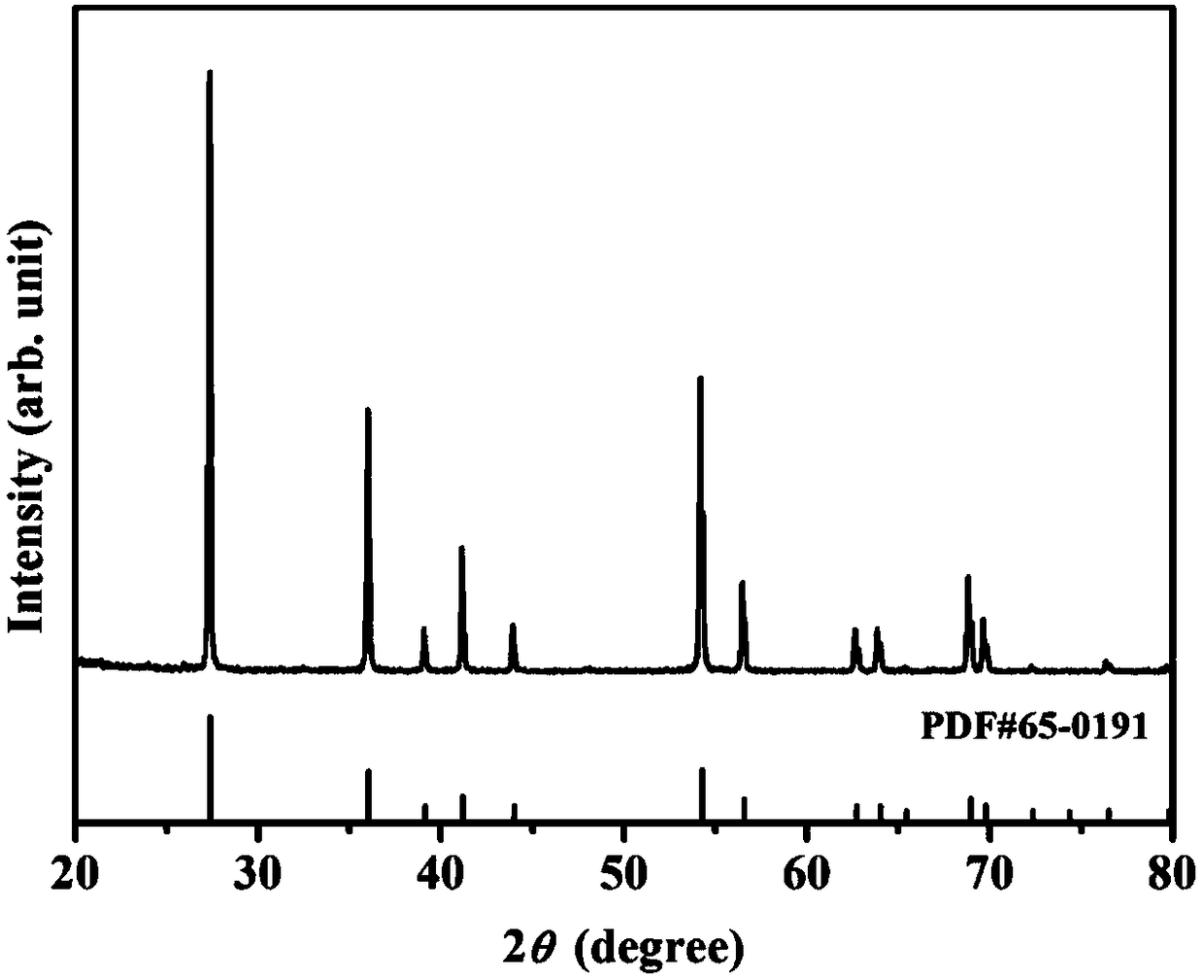

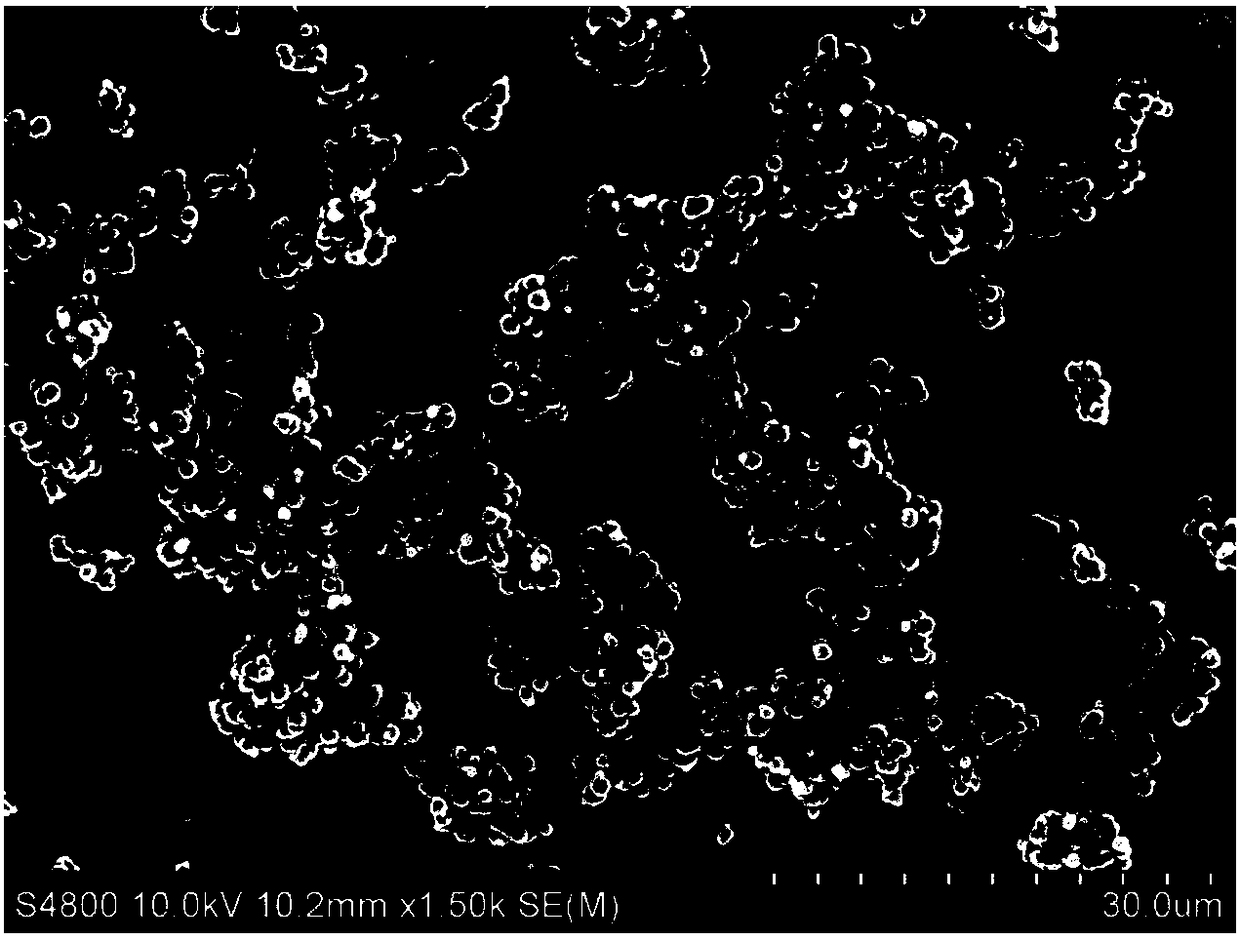

Method for preparing doped nano titanium dioxide powder by microwave hydrothermal method

A nano-titanium dioxide, microwave hydrothermal method technology, applied in titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide and other directions, can solve the problems of long reaction time of nano-TiO2 powder, achieve short preparation cycle, save energy, Guaranteed effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing doped nano-titanium dioxide powder by microwave hydrothermal method, comprising the steps of:

[0032] Accurately weigh NbCl according to the molar ratio of 1:1 5 , InCl 3 4H 2 O and add an appropriate amount of absolute ethanol and continue to stir to make it completely dissolved, respectively, to obtain uniform A solution and B solution.

[0033] (1) Accurately weigh NbCl according to the molar ratio of 1:1 5 , InCl 3 4H 2 O and add an appropriate amount of absolute ethanol and continue to stir to make it completely dissolved, respectively, to obtain uniform A solution and B solution.

[0034] (2) Measure tetra-n-butyl titanate and place it in a beaker, add an appropriate amount of absolute ethanol dropwise, and continue to stir to obtain a uniform C solution, wherein tetra-n-butyl titanate and NbCl in step (1) 5 The molar ratio is 18:1;

[0035] (3) Slowly drop the B solution into the A solution, and continue to stir evenly to obtain the D...

Embodiment 2

[0040] A method for preparing doped nano-titanium dioxide powder by microwave hydrothermal method, comprising the steps of:

[0041] (1) Accurately weigh NbCl according to the molar ratio of 1:1 5 and InCl 3 4H 2 O and add an appropriate amount of absolute ethanol and continue to stir to make it completely dissolved, respectively, to obtain uniform A solution and B solution.

[0042] (2) Measure tetra-n-butyl titanate and place it in a beaker, add an appropriate amount of absolute ethanol dropwise, and continue to stir to obtain a uniform C solution, wherein tetra-n-butyl titanate and NbCl in step (1) 5 The molar ratio is 18:1;

[0043] (3) Slowly drop the B solution into the A solution, and continue to stir evenly to obtain the D solution;

[0044] (4) Slowly drop the D solution obtained in the step (3) into the C solution, and continue stirring until a uniform mixed solution is obtained;

[0045] (5) Select concentrated hydrochloric acid to regulate the pH of the soluti...

Embodiment 3

[0048] A method for preparing doped nano-titanium dioxide powder by microwave hydrothermal method, comprising the steps of:

[0049] (1) Accurately weigh NbCl according to the molar ratio of 1:1 5 , InCl 3 4H 2 O and add an appropriate amount of absolute ethanol and continue to stir to make it completely dissolved, respectively, to obtain uniform A solution and B solution.

[0050] (2) Measure tetra-n-butyl titanate and place it in a beaker, add an appropriate amount of absolute ethanol dropwise, and continue to stir to obtain a uniform C solution, wherein tetra-n-butyl titanate and NbCl in step (1) 5 The molar ratio is 18:1;

[0051] (3) Slowly drop the B solution into the A solution, and continue to stir evenly to obtain the D solution;

[0052] (4) Slowly drop the D solution obtained in step (3) into the solution C, and keep stirring until a uniform mixed solution is obtained;

[0053] (5) select concentrated hydrochloric acid to regulate solution pH for use, slowly ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com