Light magnesium oxide double-reduction carbonization preparation method

A light magnesia and heavy magnesia technology, applied in directions such as magnesia, can solve the problems of reducing production cost, reducing investment, shortening process, etc., to simplify production process, improve product quality index, and increase solution concentration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

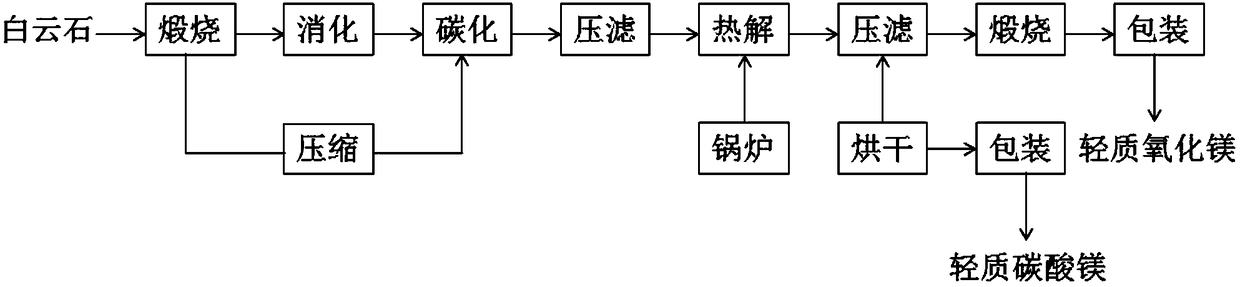

Image

Examples

preparation example Construction

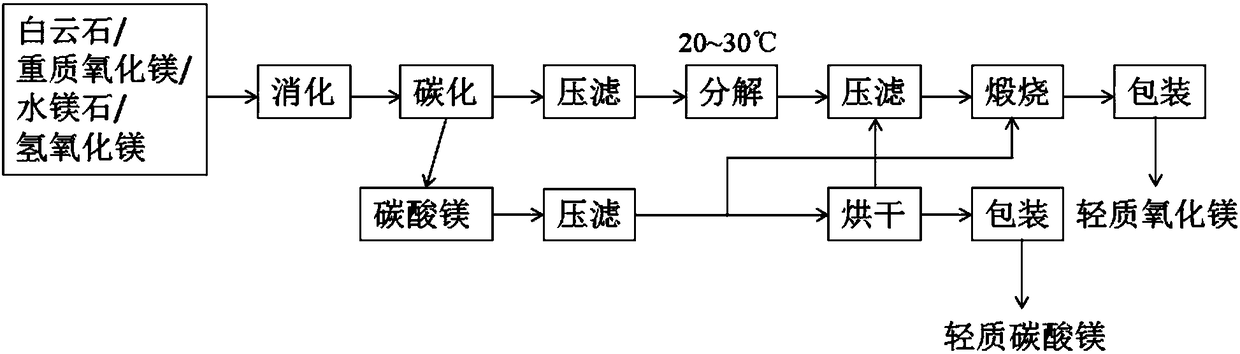

[0026] The invention provides a double carbon reduction preparation method of light magnesia. The raw materials are digested, carbonized, press-filtered once, decomposed, pressed-filtered twice and calcined in sequence to obtain light magnesia; wherein the raw materials are selected from Baiyun One or more of stone, heavy magnesia, brucite and magnesium hydroxide, specifically including steps as follows.

[0027] Digestion: Mix the raw materials and water at a mass ratio of 1: (75-81), then control the digestion temperature to 85-90°C, the digestion time to 0.5-0.8h, and keep stirring during the digestion process.

[0028] Carbonization: In the carbonization tower, quantitative flow layered carbonization is carried out on the digested product, so that the carbonization reaction can be carried out at different temperatures and different flow rates of carbon dioxide;

[0029] Quantitative flow layered carbonization includes the first carbonization, second carbonization and third...

Embodiment 1

[0036] This embodiment provides a double reduction carbonization preparation method of light magnesia, which is to digest, carbonize, first press filter, decompose, second press filter and calcinate the raw material dolomite in order to obtain light magnesia, which specifically includes the steps as follows.

[0037] Digestion: Mix the raw material dolomite and water at a mass ratio of 1:78, then control the temperature of digestion to 87°C, the time of digestion to 0.6h, and keep stirring during the digestion process.

[0038] Carbonization: In the carbonization tower, quantitative flow layered carbonization is carried out on the digested product, so that the carbonization reaction can be carried out at different temperatures and different flow rates of carbon dioxide;

[0039] Quantitative flow layered carbonization includes the first carbonization, second carbonization and third carbonization in sequence; in the first carbonization, the initial pH value is adjusted to 7.7, ...

Embodiment 2

[0046] This embodiment provides a double reduction carbonization preparation method of light magnesia, which is to digest, carbonize, first press filter, decompose, second press filter and calcinate the raw material dolomite in order to obtain light magnesia, which specifically includes the steps as follows.

[0047] Digestion: Mix the raw material dolomite and water at a mass ratio of 1:75, then control the digestion temperature to 85°C, and the digestion time to 0.5h, and keep stirring during the digestion process.

[0048] Carbonization: In the carbonization tower, quantitative flow layered carbonization is carried out on the digested product, so that the carbonization reaction can be carried out at different temperatures and different flow rates of carbon dioxide;

[0049] Quantitative flow layered carbonization includes the first carbonization, second carbonization and third carbonization in sequence; in the first carbonization, the initial pH value is adjusted to 7.6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com