Lightweight high-impact-resistance high-modulus multilayer composite board easy in thermal forming and preparation method thereof

A multi-layer composite and composite sheet technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve problems such as tensile impact and other performance gaps, poor forming performance, and increased sheet processing difficulty. , to achieve the effect of good formability and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

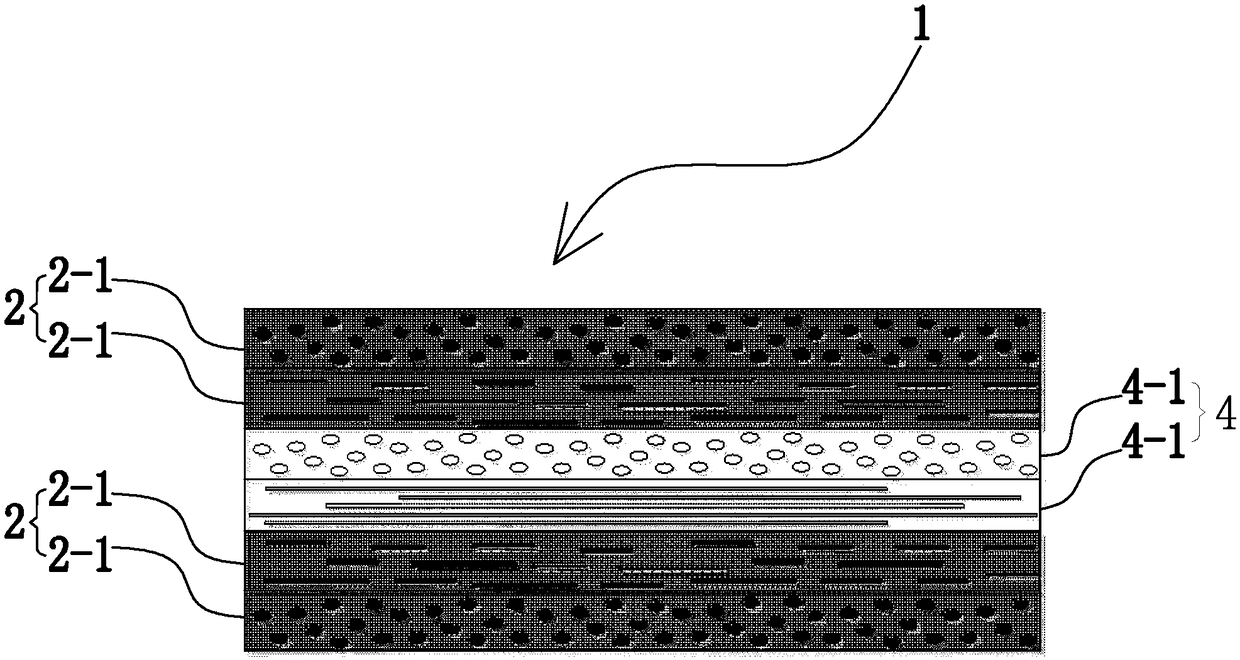

[0033] Embodiment one: if figure 1 As shown, a light-weight, high-impact, high-modulus fiber-reinforced multi-layer composite sheet that is easy to be thermoformed includes a composite sheet body 1; the composite sheet body 1 is composed of two or more layers of composite layer sheets; The composite plate body 1 includes an outer layer 2 and an inner layer 4; the outer layer 2 and the inner layer 4 are composited into a plate by heating and pressing, the outer layer 2 is a fiber-reinforced thermoplastic composite material layer, and the inner layer 4 is an ultra-high molecular weight polymer Ethylene fiber-reinforced resin layer; inner layer 4 includes two layers of ultra-high molecular weight polyethylene fiber-reinforced resin layer 4-1; outer layer 2 includes two layers of fiber-reinforced thermoplastic composite material 2-1, two layers of fiber-reinforced thermoplastic The composite material layer 2-1 is arranged on the upper and lower ends of the two ultra-high molecular...

Embodiment 2

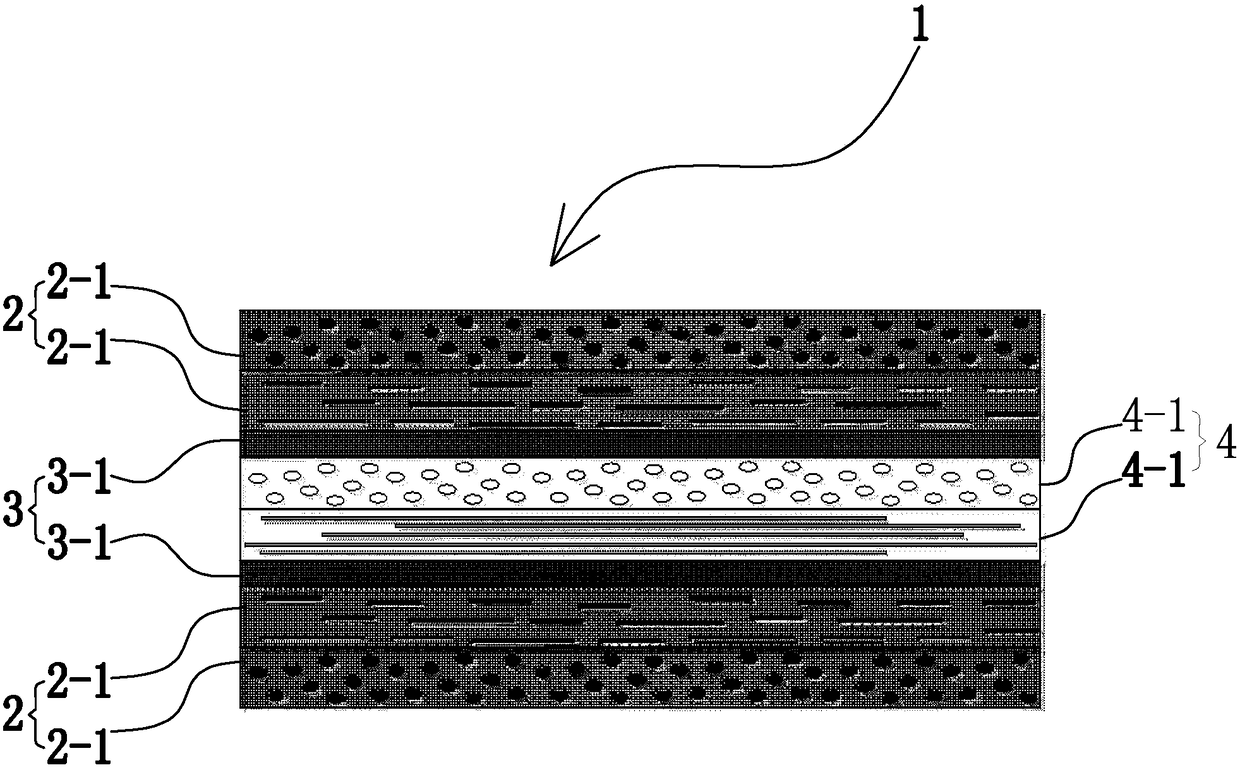

[0050] Such as figure 2 As shown, a light-weight, high-impact, high-modulus fiber-reinforced multilayer composite sheet that is easy to be thermoformed also includes an intermediate layer 3, and the intermediate layer 3 is located between the outer layer 2 and the inner layer 4. The intermediate layer 3 It is a thermoplastic adhesive film layer; the thermoplastic adhesive film layer is polypropylene-based, EVA-based, vinyl, or thermoplastic polyurethane substrate, and its thickness is 0.1 mm to 1 mm; the middle layer 3 includes two layers of thermoplastic adhesive film layers 3-1, the two thermoplastic adhesive film layers 3-1 are respectively located between the ultra-high molecular weight polyethylene fiber reinforced resin layer 4-1 and the fiber reinforced thermoplastic composite material layer 2-1;

[0051] A method for preparing a light-weight, high-impact, high-modulus fiber-reinforced multilayer composite sheet that is easy to be thermoformed is characterized in that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com