Method for preparing high-purity spherical ruthenium powder

A ruthenium powder and spherical technology is applied in the field of preparation of high-purity spherical ruthenium powder, which can solve the problem of high impurity content of ruthenium powder, and achieve the effects of low impurity content and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

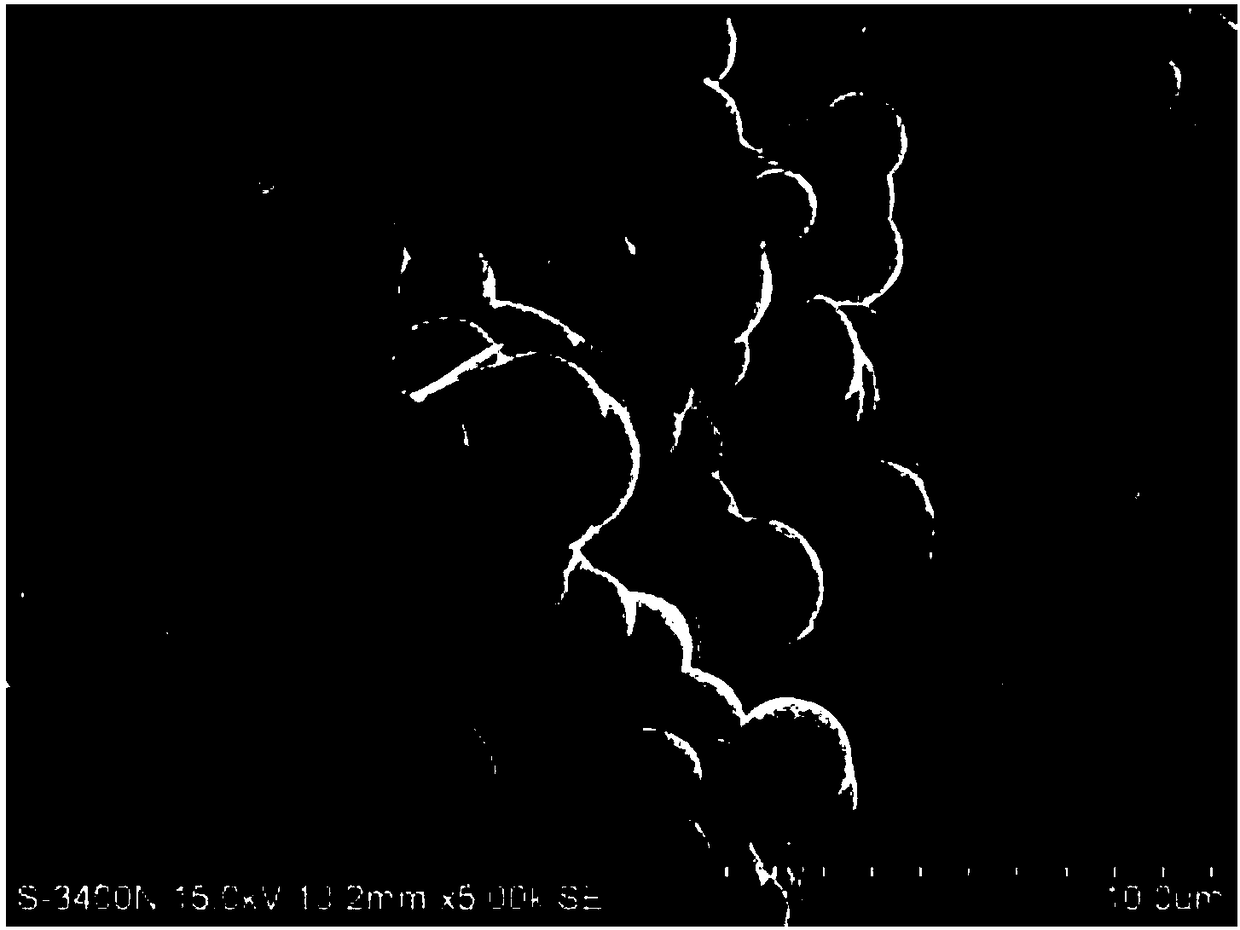

[0022] Embodiment 1, see attached figure 1 , the solid ruthenium trichloride is dissolved with high-grade pure hydrochloric acid+deionized water, and the gained ruthenium solution removes cationic impurities by a cation exchange resin to obtain a pure ruthenium solution. :8 Add superior-grade pure urea, age for 24h, then heat the solution to 90°C, stir and react at a constant temperature for 4h, a hydrolysis precipitation reaction occurs, and generate a spherical ruthenium powder precursor—a hydrated ruthenium oxide, which is separated by filtration, washed, and dried; The precursor was placed in a tube furnace, calcined and dehydrated at a constant temperature of 300°C for 1 hour, continued to heat up to 600°C, introduced high-purity hydrogen, and reduced for 4 hours at a constant temperature, and then passed in nitrogen to cool to room temperature to obtain ruthenium powder; then the obtained ruthenium The powder was boiled and washed with nitric acid + hydrofluoric acid in ...

Embodiment 2

[0023] Embodiment 2, see attached figure 1 , the solid ruthenium trichloride is dissolved with superior-grade pure hydrochloric acid+deionized water, and the gained ruthenium solution removes cationic impurities by a cation exchange resin to obtain a pure ruthenium solution; the pH of the ruthenium solution is adjusted to be 5, by ruthenium: urea molar ratio of 1: 6 Add high-grade pure urea, age for 24 hours, then heat the solution to 90°C, stir and react at a constant temperature for 4 hours, hydrolysis and precipitation reaction occurs, and a spherical ruthenium powder precursor - hydrated ruthenium oxide is generated, which is separated by filtration, washed and dried; The body is placed in a tube furnace at a constant temperature of 350°C for calcination and dehydration for 2 hours, then the temperature is raised to 650°C, high-purity hydrogen is introduced, and the constant temperature is reduced for 3 hours, and then nitrogen is passed into and cooled to room temperature ...

Embodiment 3

[0024] Embodiment 3, see attached figure 1 , the solid ruthenium trichloride is dissolved with high-grade pure hydrochloric acid+deionized water, and the gained ruthenium solution removes cationic impurities by a cation exchange resin to obtain a pure ruthenium solution. 6 Add high-grade pure urea, age for 24 hours, then heat the solution to boiling, stir and react at constant temperature for 4 hours, hydrolysis and precipitation reaction occurs, and generate spherical ruthenium powder precursor——hydrated ruthenium oxide, which is separated by filtration, washed, and dried; Place it in a tube furnace at a constant temperature of 350°C for calcination and dehydration for 2 hours, continue to heat up to 650°C, feed high-purity hydrogen, reduce at a constant temperature for 3 hours, and then feed nitrogen to cool to room temperature to obtain ruthenium powder; then the obtained ruthenium powder is in Nitric acid + hydrofluoric acid was used to boil and wash in a polytetrafluoroet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com