Composite photocatalyst for treating phenol-containing wastewater as well as preparation method and application thereof

A composite photocatalyst technology, which is applied in the field of photocatalytic materials and environmental protection, can solve the problems of small specific surface area, restrictions on wide-scale popularization and application, and difficulty in recycling, and achieve large specific surface area, improved photocatalytic degradation effect, and easy preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

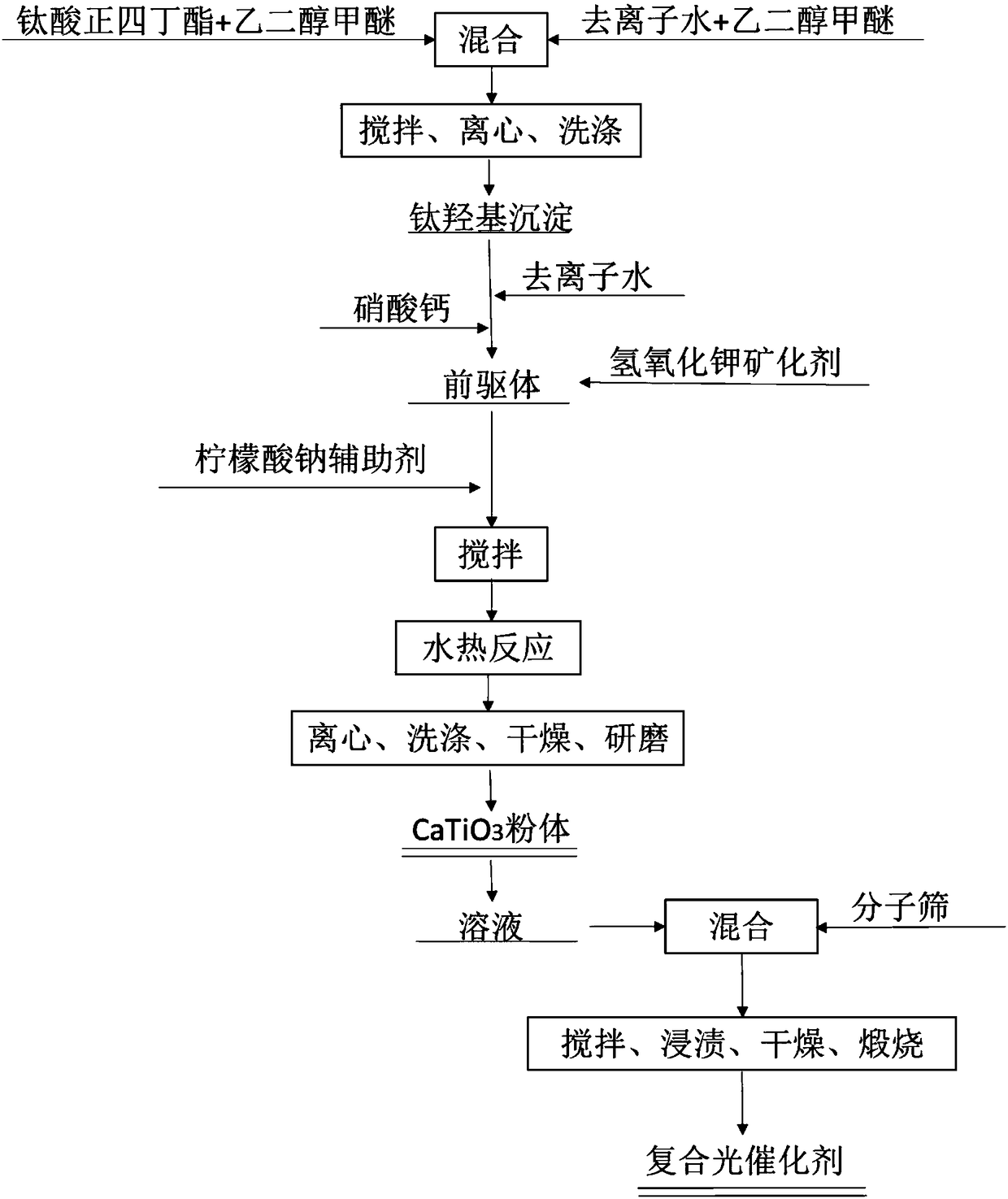

[0071] A composite photocatalyst for treating phenol-containing wastewater is a composite photocatalyst that uses molecular sieve as a carrier and supports calcium titanate by an equal volume impregnation method.

[0072] Among them, calcium titanate is the main material for photocatalytic degradation. After the calcium titanate is compounded with the molecular sieve, the composite photocatalyst is obtained by drying and high-temperature calcination.

[0073] In the composite photocatalyst for treating phenol-containing wastewater, the loading rate of calcium titanate is 5%;

[0074] The composite photocatalyst for treating phenol-containing wastewater is a white powdery solid with a specific surface area of 220.259m 2 / g, pore volume 0.254636cm 3 / g, average hole radius

[0075] The molecular sieve is ZSM-5 molecular sieve.

[0076] A preparation method of a composite photocatalyst for treating phenol-containing wastewater, including the following steps:

[0077] step 1:

[0078] (1) ...

Embodiment 2

[0093] A composite photocatalyst for treating phenol-containing wastewater is a photocatalyst that uses calcium titanate as the main material for photocatalytic degradation, molecular sieve as a carrier, and is loaded with calcium titanate by an isometric impregnation method. After the calcium titanate is compounded with the molecular sieve by an equal volume impregnation method, the compound photocatalyst is obtained by drying and high-temperature calcination.

[0094] In the composite photocatalyst for treating phenol-containing wastewater, the loading rate of calcium titanate is 3%;

[0095] The composite photocatalyst for treating phenol-containing wastewater is a white powdery solid with a specific surface area of 212.924m 2 / g, pore volume 0.179389cm 3 / g, average hole radius

[0096] Wherein, the molecular sieve is ZSM-5 molecular sieve.

[0097] A preparation method of a composite photocatalyst for treating phenol-containing wastewater, including the following steps:

[0098...

Embodiment 3

[0111] A composite photocatalyst for treating phenol-containing wastewater is a photocatalyst that uses calcium titanate as the main material for photocatalytic degradation, molecular sieve as a carrier, and is loaded with calcium titanate by an isometric impregnation method. After the calcium titanate is compounded with the molecular sieve by an equal volume impregnation method, the compound photocatalyst is obtained by drying and high-temperature calcination.

[0112] In the composite photocatalyst for treating phenol-containing wastewater, the loading rate of calcium titanate is 3%;

[0113] The composite photocatalyst for treating phenol-containing wastewater is a white powdery solid with a specific surface area of 340.669m 2 / g, pore volume 0.664242cm 3 / g, average hole radius

[0114] Wherein, the molecular sieve is β molecular sieve.

[0115] A preparation method of a composite photocatalyst for treating phenol-containing wastewater, including the following steps:

[0116] st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com