C/C (carbon-carbon) composite material bone fracture plate and preparation method thereof

A composite material and bone plate technology, used in medical science, surgery, coating, etc., can solve the problems of rejection reaction, prone to fiber burrs, surrounding tissue irritation, etc., and achieve good fatigue performance and good biocompatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of the C / C composite bone plate of the present invention, comprising the following steps:

[0042] Cut the 0° non-woven fabric, carbon fiber mesh tire and 90° non-woven fabric into the size of the design block, and cut the cut 0° non-woven fabric, carbon fiber mesh tire and 90° non-woven fabric according to the mechanical structure design requirements The layers are stacked alternately in sequence, and needle-punched carbon fibers are filled between the layers as a reinforcing phase.

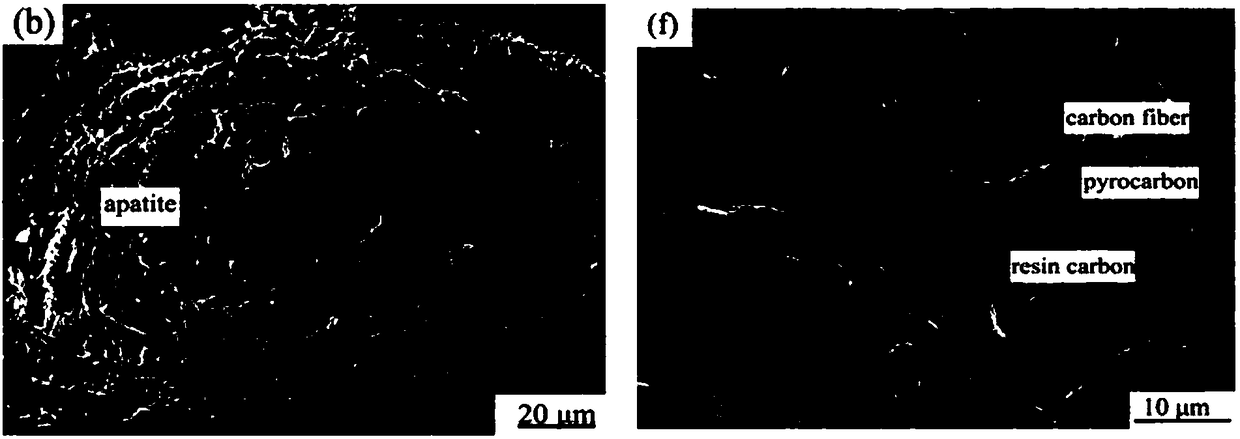

[0043] The obtained alternately laminated product is placed on a heating platform for preheating, and two layers of pyrolytic carbon are coated on the alternately laminated product. The thickness of each layer of pyrolytic carbon is 3mm, and the total amount of pyrolytic carbon on the product is The coating amount is 5% of the mass of the product, and the resin carbon is filled outside the pyrolytic carbon layer by the liquid phase impregnation method, and the filling...

Embodiment 2

[0052] A preparation method of the C / C composite bone plate of the present invention, comprising the following steps:

[0053] Cut the 0° non-woven fabric, carbon fiber mesh tire and 90° non-woven fabric into the size of the design block, and cut the cut 0° non-woven fabric, carbon fiber mesh tire and 90° non-woven fabric according to the mechanical structure design requirements The layers are stacked alternately in sequence, and needle-punched carbon fibers are filled between the layers as a reinforcing phase.

[0054] The obtained alternately laminated product is placed on a heating platform for preheating, and two layers of pyrolytic carbon are coated on the alternately laminated product. The thickness of each layer of pyrolytic carbon is 2mm. The total amount of pyrolytic carbon on the product is The coating amount is 6% of the mass of the product, and resin carbon is filled outside the pyrolytic carbon layer by liquid phase impregnation method. The filling amount of resin...

Embodiment 3

[0059] A preparation method of the C / C composite bone plate of the present invention, comprising the following steps:

[0060] Cut the 0° non-woven fabric, carbon fiber mesh tire and 90° non-woven fabric into the size of the design block, and cut the cut 0° non-woven fabric, carbon fiber mesh tire and 90° non-woven fabric according to the mechanical structure design requirements The layers are stacked alternately in sequence, and needle-punched carbon fibers are filled between the layers as a reinforcing phase.

[0061] The obtained alternately laminated product is placed on a heating platform for preheating, and two layers of pyrolytic carbon are coated on the alternately laminated product. The thickness of each layer of pyrolytic carbon is 4mm. The total amount of pyrolytic carbon on the product is The coating amount is 8% of the mass of the product, and resin carbon is filled outside the pyrolytic carbon layer by liquid phase impregnation method. The filling amount of resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com