Variable friction pendulum shock insulation support

A seismic isolation bearing and variable friction technology, which is applied in the directions of earthquake resistance, building type, and building, etc., can solve the problems of unguaranteed bearing safety and large horizontal displacement of the seismic isolation layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

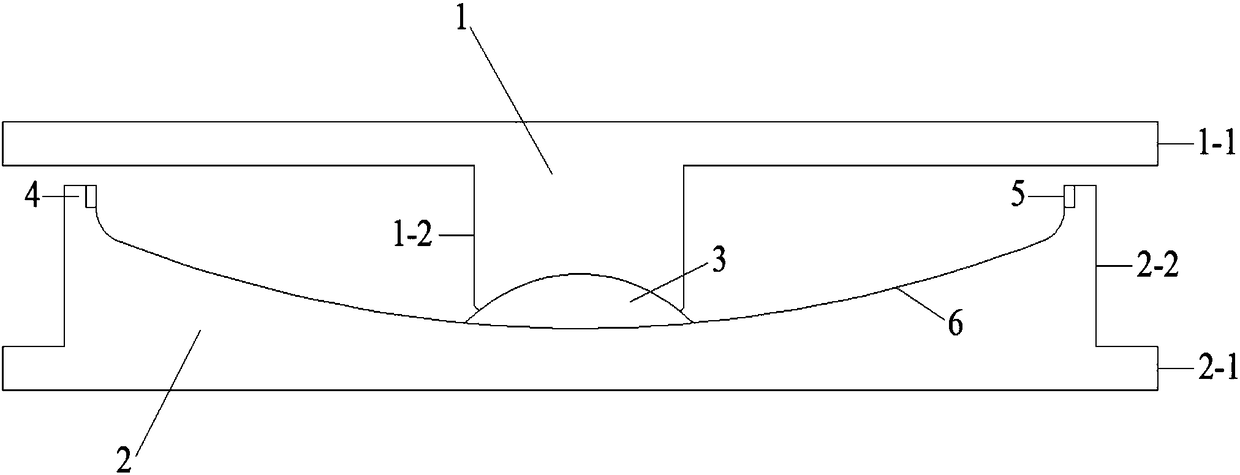

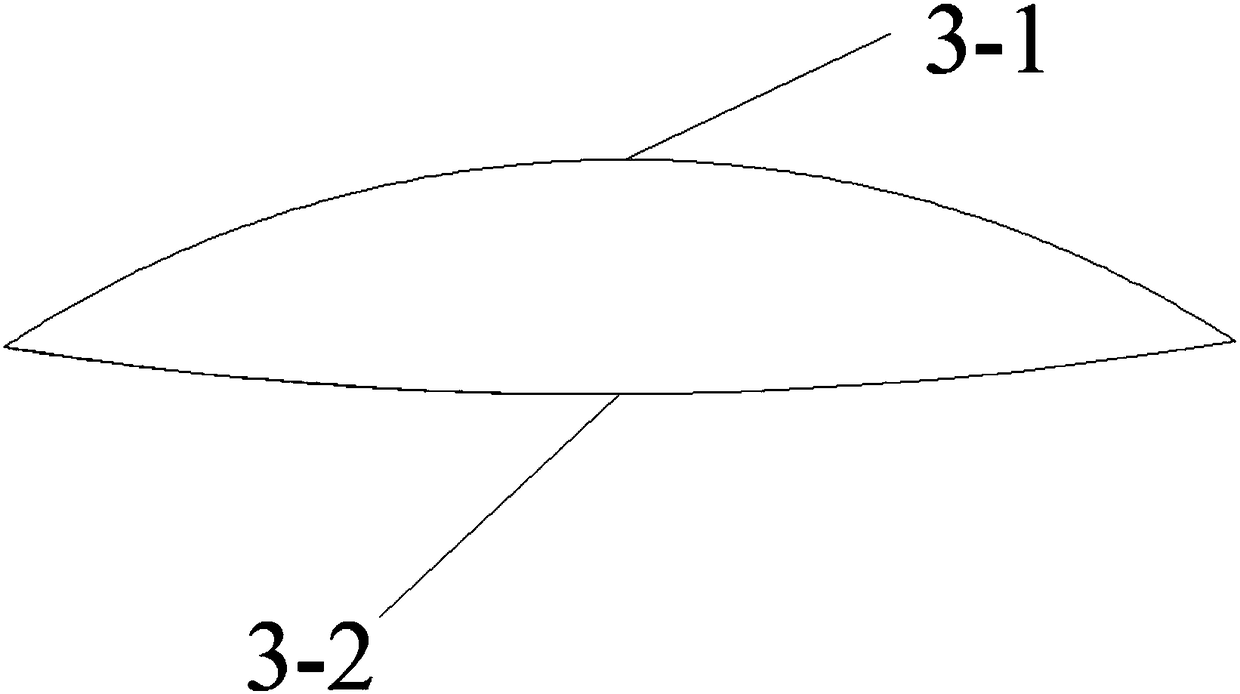

[0024] combine figure 1 , figure 2 As shown, a variable friction pendulum shock-isolation support includes an upper connection block, a lower connection block located below the upper connection block, and a slider. The upper surface of the lower connection block is provided with a lower friction layer. The upper surface of the slider is in spherical contact with the lower surface of the upper connecting block, and the lower surface of the slider is in spherical contact with the upper surface of the lower connecting block, that is, the lower surface of the slider is in spherical contact with the lower friction layer on the upper surface of the lower connecting block. The slider is made of high strength alloy.

[0025] The upper connecting block includes an upper connecting plate and an upper vertical block integrally formed, the columnar upper vertical block is located at the lower end of the upper connecting plate, and the lower surface of the upper connecting block is the ...

Embodiment 2

[0036] Except the following technical features, all the other unmentioned technical features are the same as embodiment 1.

[0037] In Embodiment 2, there is only one spherical concave surface of the lower connecting block, that is, the radius of curvature of the spherical concave surface of the lower connecting block is a constant value. The lower friction layer set on the spherical concave surface of the lower connection block is alternately divided into friction constant value areas and friction transition areas from the inside to the outside. The friction coefficient of the lower friction layer in the friction constant value area is a constant value. The friction coefficient of the friction layer is a variable value. The lower friction layer corresponding to the friction transition zone should ensure the smooth transition of the lower friction layer corresponding to two adjacent friction constant value zones. From the top view direction, all friction constant value zones C...

Embodiment 3

[0039] Except the following technical features, all the other unmentioned technical features are the same as embodiment 1.

[0040]In the present embodiment 3, the quantity of the spherical concave surface of the lower connection block has two, that is, the radius of curvature of the spherical concave surface of the lower connection block has two, and both radii of curvature are fixed values, that is, the spherical concave surface of the center and the outer surface Spherical concave. The lower friction layer set on the spherical concave surface of the lower connection block is alternately divided into friction constant value areas and friction transition areas from the inside to the outside. The friction coefficient of the lower friction layer in the friction constant value area is a constant value. The friction coefficient of the friction layer is a variable value. The lower friction layer corresponding to the friction transition zone should ensure the smooth transition of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com