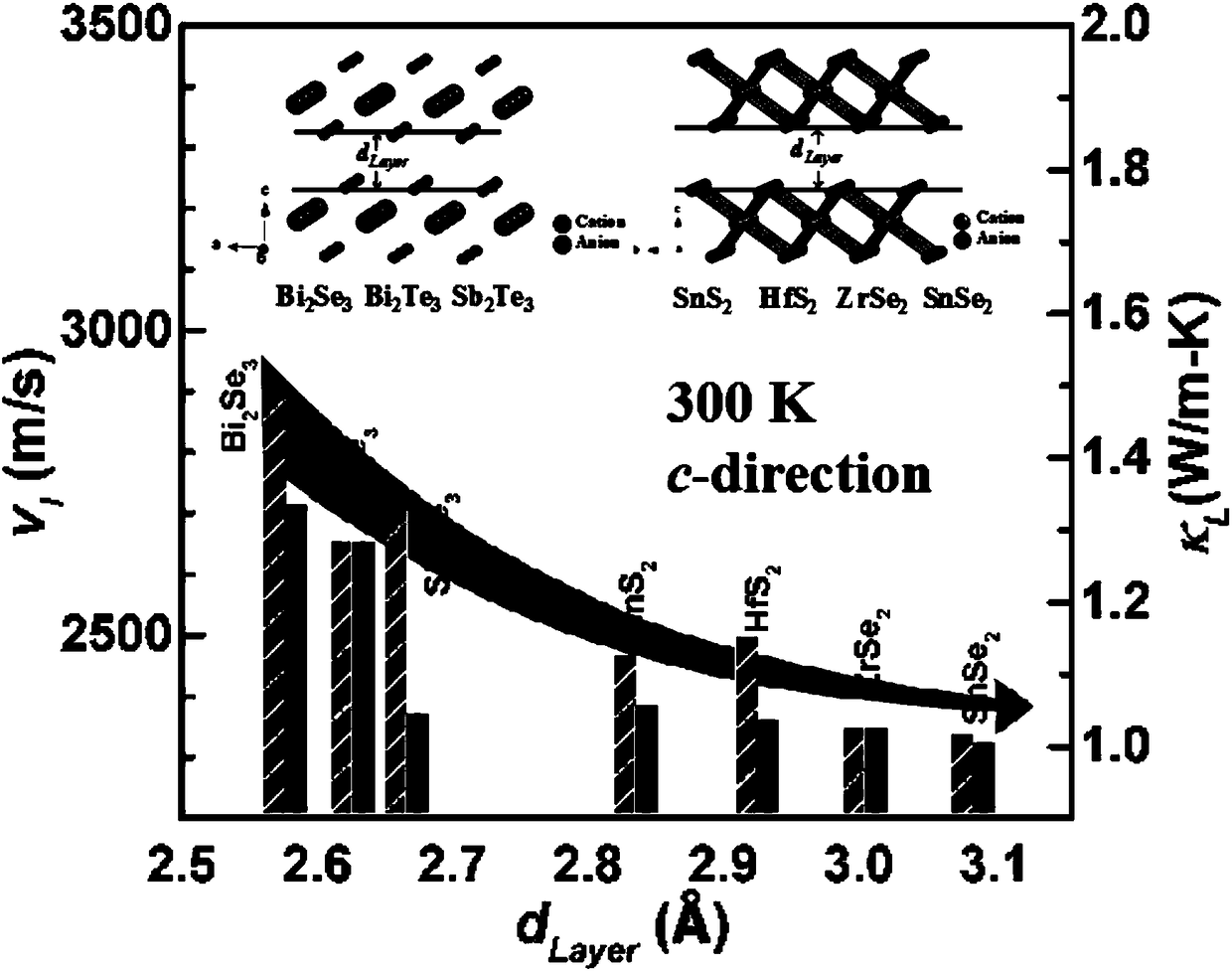

Polycrystalline SnSe2 low-cost thermoelectric material and preparation method thereof

A thermoelectric material, low-cost technology, applied in the fields of polycrystalline material growth, thermoelectric device junction lead-out materials, chemical instruments and methods, etc. Performance, effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] Polycrystalline SnSe 2 The preparation method of low-cost thermoelectric material preferably comprises the following steps:

[0044] (1) Vacuum packaging: according to the stoichiometric ratio, weigh the elemental Sn, Se and SnBr 2 Compounds, mixed uniformly as raw materials and vacuum-packed in quartz tubes;

[0045] (2) Melting reaction quenching: heating the quartz tube to make the raw materials fully react in the molten state, and then quenching to obtain the first ingot;

[0046] (3) heat treatment and quenching: the first ingot is vacuum-packed in another quartz tube, quenched and cooled after heat treatment to obtain the second ingot;

[0047] (4) Pressurized sintering: the second ingot is ground into powder, placed in a graphite mold, sintered by vacuum and high temperature hot pressing, and then cooled to obtain a bulk material, which is the polycrystalline SnSe 2 Low-cost thermoelectric materials.

[0048] As a preferred embodiment of the present invention...

Embodiment 1

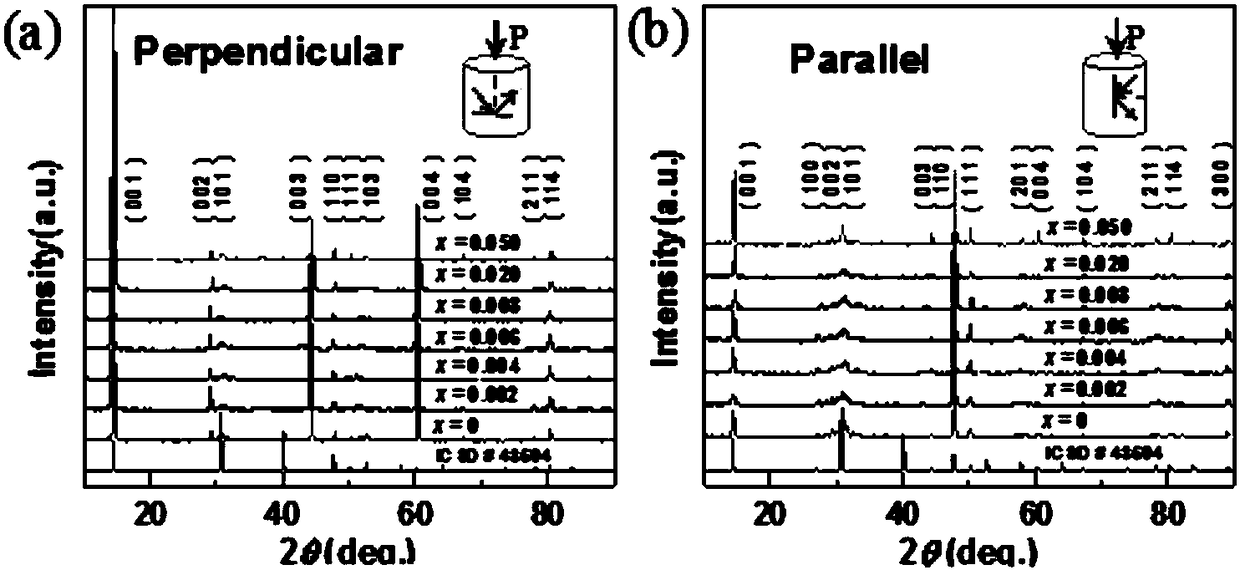

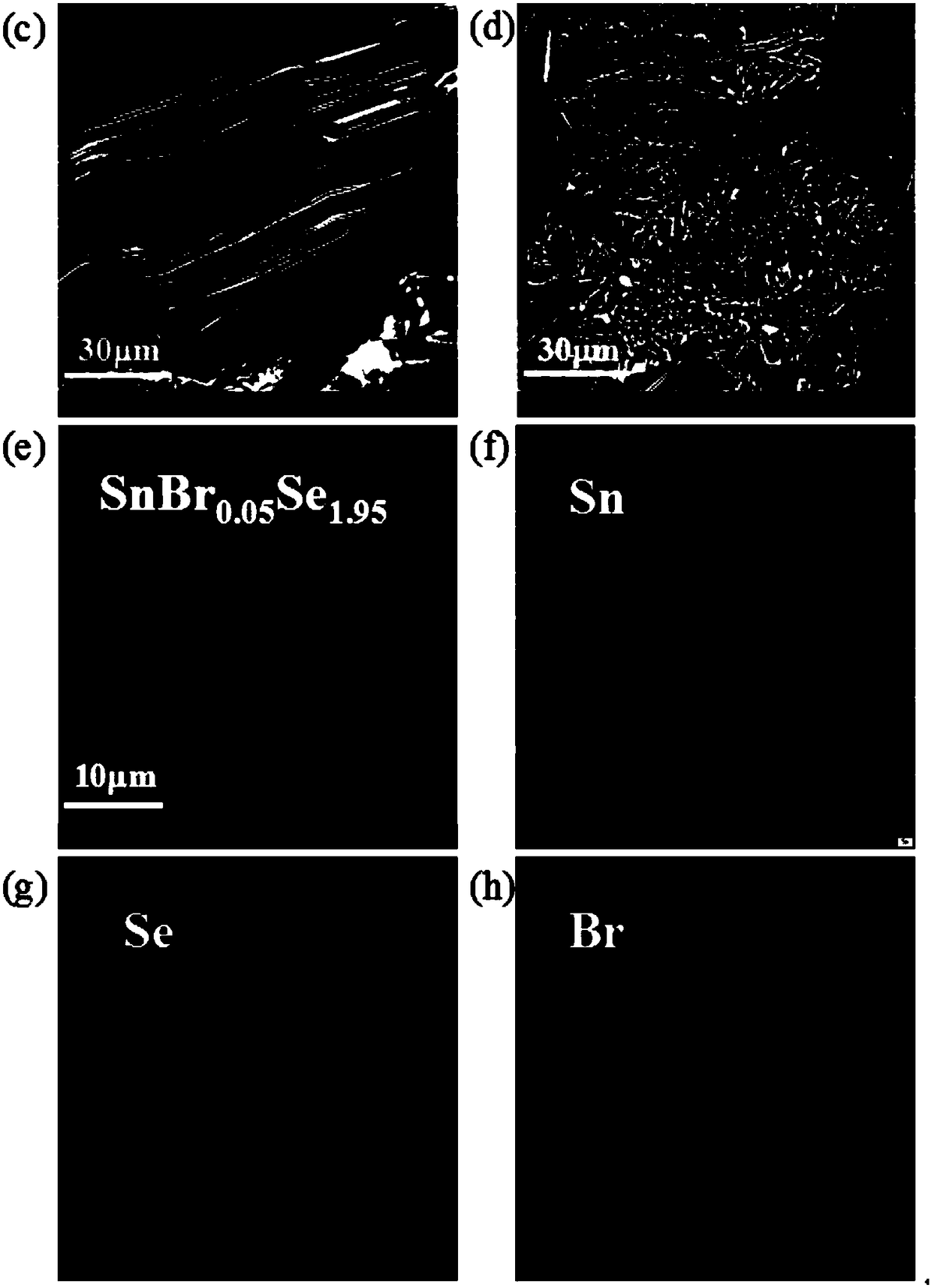

[0055] A polycrystalline SnSe 2 Low-cost thermoelectric material with the chemical formula SnBr x Se 2-x , x=0~0.05, in this embodiment by taking x=0, 0.002, 0.004, 0.006, 0.008, 0.02 and 0.05 (when x=0, the chemical formula is SnSe 2 , when x=0.002, 0.004, 0.006, 0.008, 0.02 and 0.05, that is, by doping different concentrations of Br to optimize the carrier concentration), according to the following preparation method, obtain different carrier concentrations of SnBr x Se 2-x Block material:

[0056] (1) According to different values of x, it is composed of SnBr x Se 2-x (x=0~0.05) stoichiometric ratio Weigh the elemental raw material tin Sn, selenium Se with a purity greater than 99.99%, and the compound tin dibromide SnBr with a purity greater than 98% 2 , place the raw material in a quartz tube, and seal the quartz tube under vacuum.

[0057] (2) Suspend the quartz tube containing the raw materials in a high-temperature muffle furnace, slowly raise the temperature ...

Embodiment 2

[0072] Compared with Example 1, most of them are the same, except that in step (2) of this example: Slowly heat up to 1023K at a rate of 150K / h, and keep warm at a temperature of 1023K for 10h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com