High-yield fermentation production method of doramectin

A technology for doramectin and a production method, applied in the field of fermentation engineering, can solve the problems of unstable fermentation level, large workload, long time consumption, etc., and achieves the improvement of the doramectin fermentation level, the improvement of the fermentation level and the reduction of production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this example, the strain is a mutant strain of Streptomyces avermitilis, and the potency of the shake flask is 2500-3000 μg / mL.

[0038] To prepare different forms of precursor salts, cyclohexanecarboxylic acid and 3 mol / L NaOH, KOH, NH 4 React with OH solution to obtain sodium cyclohexylcarboxylate, potassium cyclohexylcarboxylate, and ammonium cyclohexylcarboxylate. After being fully dissolved in sterile water, prepare a 20% saline solution, filter and sterilize using a microfiltration membrane with a diameter of 0.22 μm, and set aside.

[0039] Different forms of precursor solutions were prepared, and cyclohexanecarboxylic acid was dissolved in 1.5 times the mass volume of methanol, ethanol, and acetone solvents, and sterilized by microfiltration membranes with a diameter of 0.22 μm before use.

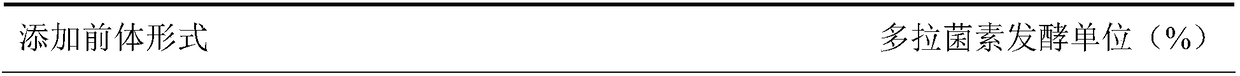

[0040] Prepare different forms of precursor emulsification system, respectively use 10 times the mass of water, 2.5 times the mass of glycerol and 10 times the water, 2.5...

Embodiment 2

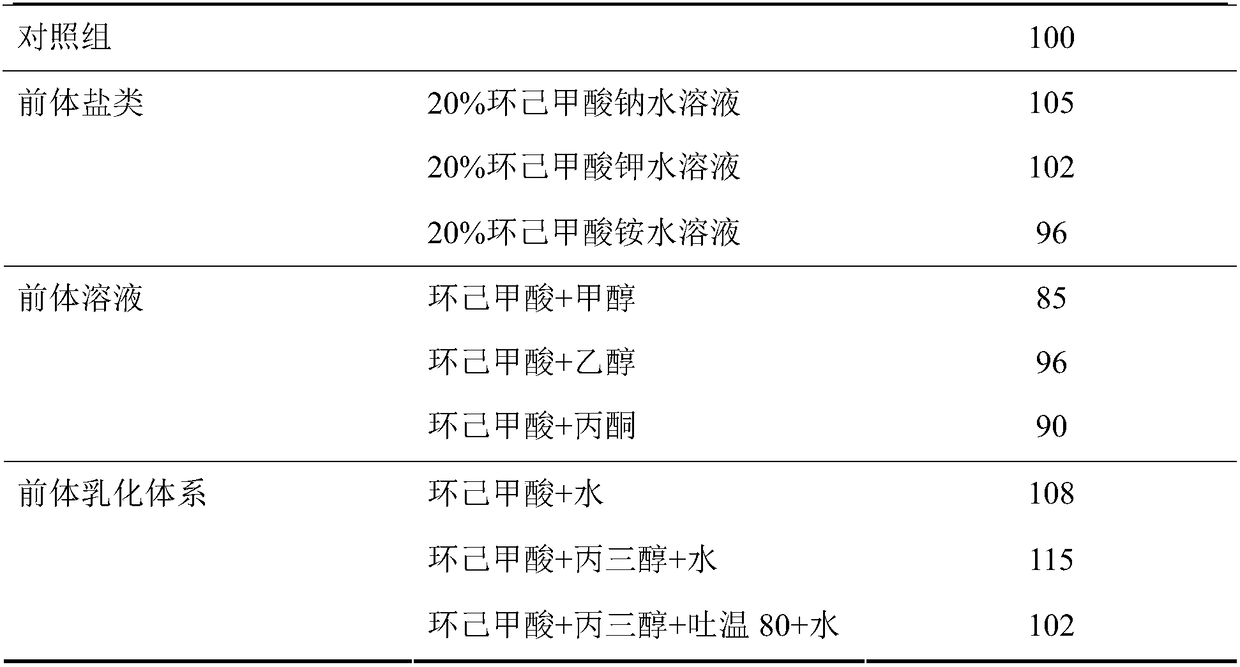

[0048] According to the results of Example 1, the key factors of the emulsification system to promote the fermentation of doramectin were investigated, and the precursor form added to the fermentation broth was an emulsification system composed of 0.20% cyclohexanecarboxylic acid+glycerol+water, cyclohexanecarboxylic acid + water emulsification system, 0.20% sodium cyclohexyl carboxylate+glycerol+water system, according to the method of embodiment 1, the precursor addition time is fermentation 24h, the control group adds 0.20% sodium cyclohexyl carboxylate in the culture medium after inoculation, the result As shown in table 2.

[0049] Table 2: Factors affecting the fermentation yield of doramectin in the precursor emulsification system

[0050]

[0051] As can be seen from Table 2, glycerol is stronger to Dora fermentation in the cyclohexanecarboxylic acid+glycerol+water emulsification system, and the water emulsification system of cyclohexanecarboxylic acid also has a hi...

Embodiment 3

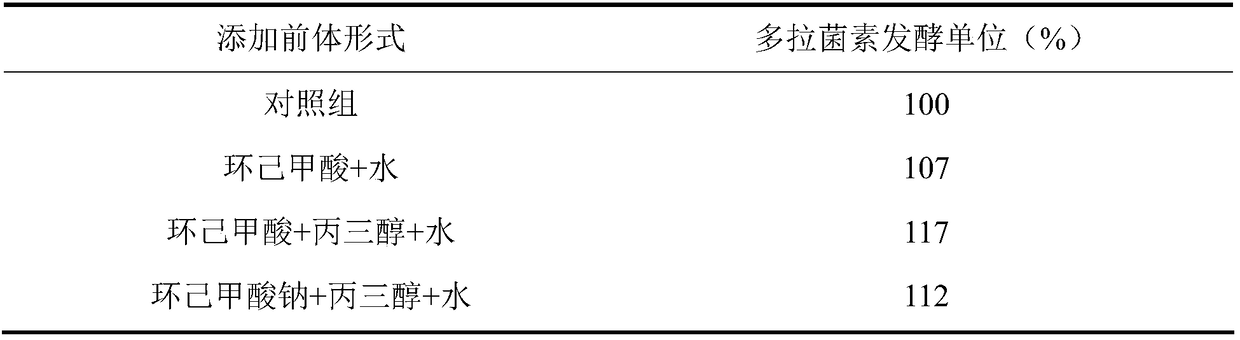

[0053] According to the results of Example 1, the emulsification system in which the precursor form is cyclohexanecarboxylic acid+glycerol+water is selected to be added to the fermentation broth, and according to the method of Example 1, different amounts of 0.01% and 0.05% are added to the fermentation medium , 0.08%, 0.10%, 0.12%, 0.15%, 0.18%, 0.20%, 0.25%, 0.30%, 0.35%, 0.40%, 0.45%, 0.50% of the precursor, the precursor addition time is 24h of fermentation, the control group 0.20% sodium cyclohexanecarboxylate was added to the inoculated medium, and the results are shown in Table 3.

[0054] Table 3: Effects of different concentrations of emulsification system precursors on the fermentation yield of doramectin

[0055]

[0056] It can be seen from Table 3 that adding 0.3% cyclohexanecarboxylic acid+glycerol+water emulsification system in the fermentation culture can significantly increase the fermentation yield of doramectin, and the effect of low concentration and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com