A temperature-resistant and oil-resistant detonator and its preparation method

A detonating tube and oil-resistant technology, which is applied to pipes, hoses, mechanical equipment, etc., can solve the problems that cannot meet the requirements of the use environment and immature resin raw material manufacturing technology, and achieve good detonation transmission reliability, excellent mechanical properties, The effect of improving the adhesion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

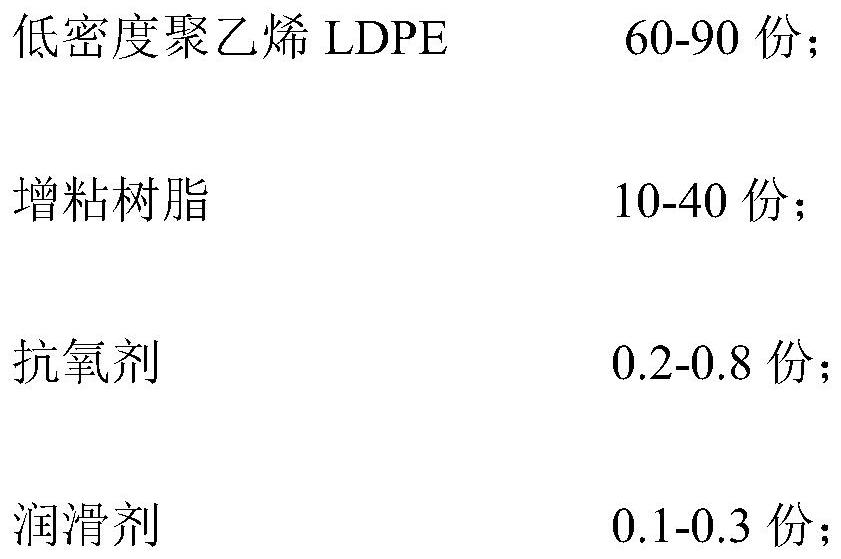

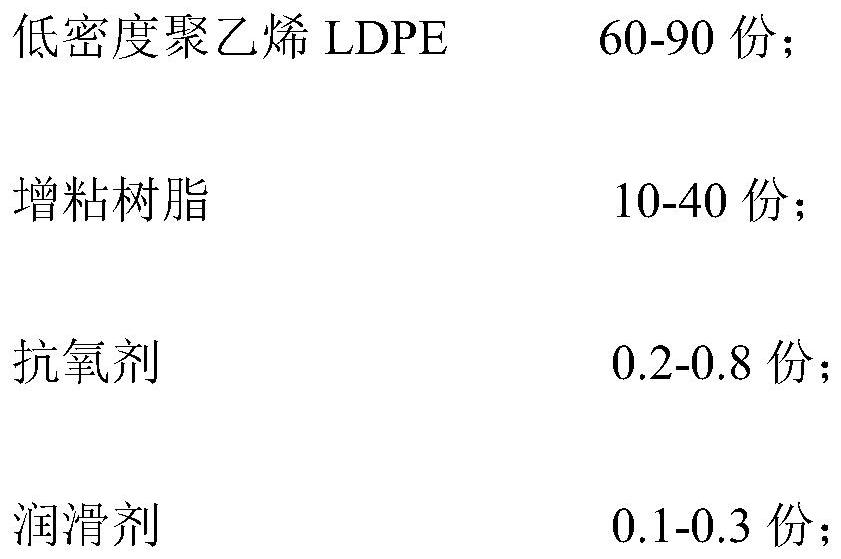

[0046] The special resin for the inner layer of the temperature-resistant and oil-resistant detonator of this embodiment includes the following components in parts by weight:

[0047] Low-density polyethylene: 70 parts; tackifying resin: 30 parts; antioxidant: 0.5 parts; lubricant: 0.2 parts. Wherein, the mixing weight ratio of EAA and Surlyn resin in tackifying resin is 7:3, and the AA content of EAA is 8.5% (weight), and melt index is 7.0g / 10min; Surlyn resin is sodium ion polymer, and melt index is 5.5g / 10min. The antioxidant is a compound of antioxidant 1010 and dilauryl alcohol ester, and the weight ratio of the two is 1:1. The lubricant is zinc stearate.

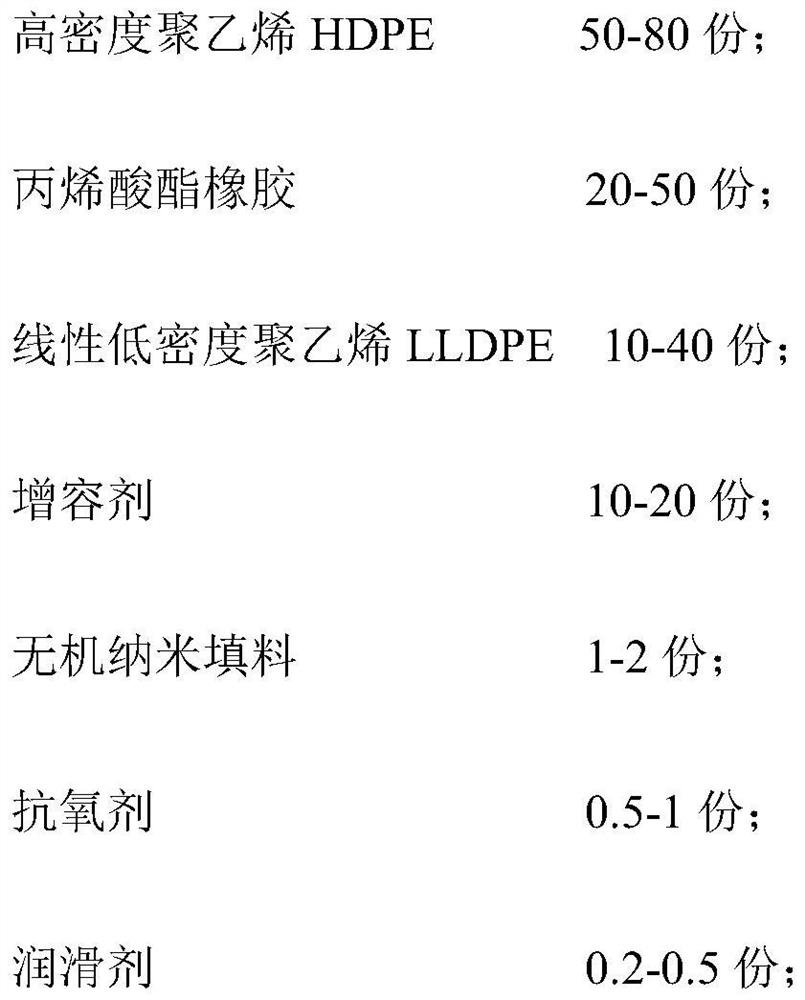

[0048] The special resin for the outer layer of the temperature-resistant and oil-resistant detonator of this embodiment includes the following components in parts by weight:

[0049] High-density polyethylene: 70 parts; acrylate rubber: 30 parts; linear low-density polyethylene: 30 parts; compatibilizer: 10 parts; in...

Embodiment 2

[0062] The special resin for the inner layer of the temperature-resistant and oil-resistant detonator of this embodiment includes the following components in parts by weight:

[0063] Low-density polyethylene: 70 parts; tackifying resin: 30 parts; antioxidant: 0.5 parts; lubricant: 0.2 parts. Wherein, the mixing weight ratio of EAA and Surlyn resin in tackifying resin is 8:2, and the AA content of EAA is 9.7% (weight), and melt index is 11.0g / 10min; Surlyn resin is a sodium ion polymer, and melt index is 5.5g / 10min. The antioxidant is a compound of antioxidant 1010 and dilauryl alcohol ester, and the weight ratio of the two is 1:2. The lubricant is zinc stearate.

[0064] The special resin for the outer layer of the temperature-resistant and oil-resistant detonator of this embodiment includes the following components in parts by weight:

[0065] High-density polyethylene: 60 parts; acrylate rubber: 40 parts; linear low-density polyethylene: 20 parts; compatibilizer: 10 part...

Embodiment 3

[0078] The special resin for the inner layer of the temperature-resistant and oil-resistant detonator of this embodiment includes the following components in parts by weight:

[0079] Low-density polyethylene: 80 parts; tackifying resin: 20 parts; antioxidant: 0.5 parts; lubricant: 0.2 parts. Wherein, the mixing weight ratio of EAA and Surlyn resin in tackifying resin is 8:2, and the AA content of EAA is 8.5% (weight), and melt index is 7.0g / 10min; Surlyn resin is sodium ion polymer, and melt index is 7.8g / 10min. The antioxidant is a compound of antioxidant 1010 and dilauryl alcohol ester, and the weight ratio of the two is 1:1. The lubricant is zinc stearate.

[0080] The special resin for the outer layer of the temperature-resistant and oil-resistant detonator of this embodiment includes the following components in parts by weight:

[0081] High-density polyethylene: 70 parts; acrylate rubber: 30 parts; linear low-density polyethylene: 30 parts; compatibilizer: 10 parts; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com