Preparation method, product and application of double-layer water gel with salt-temperature dual response

A double-response, hydrogel technology, applied in the field of double-layer hydrogel products, achieves the effect of low cost, simple operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

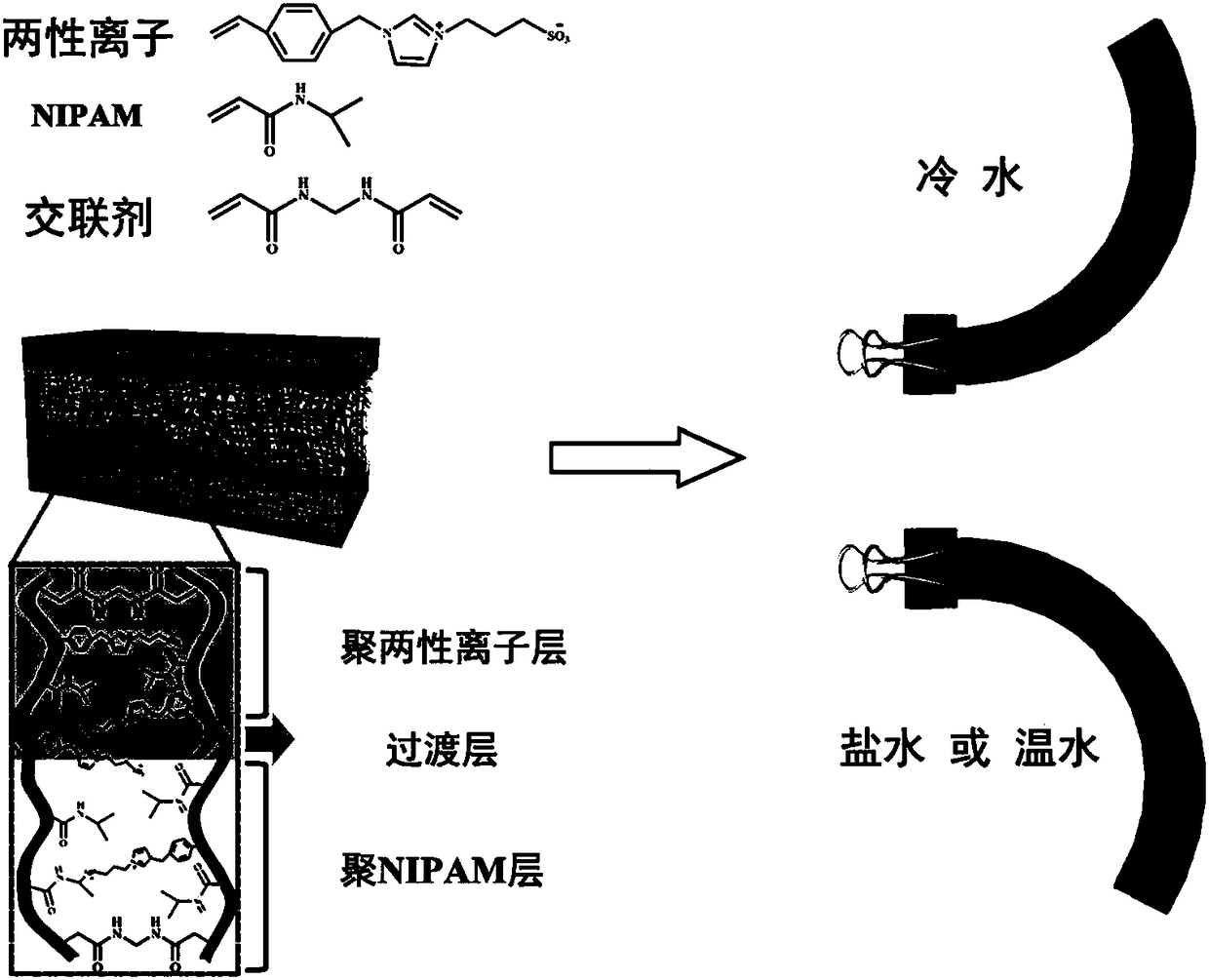

Method used

Image

Examples

Embodiment 1

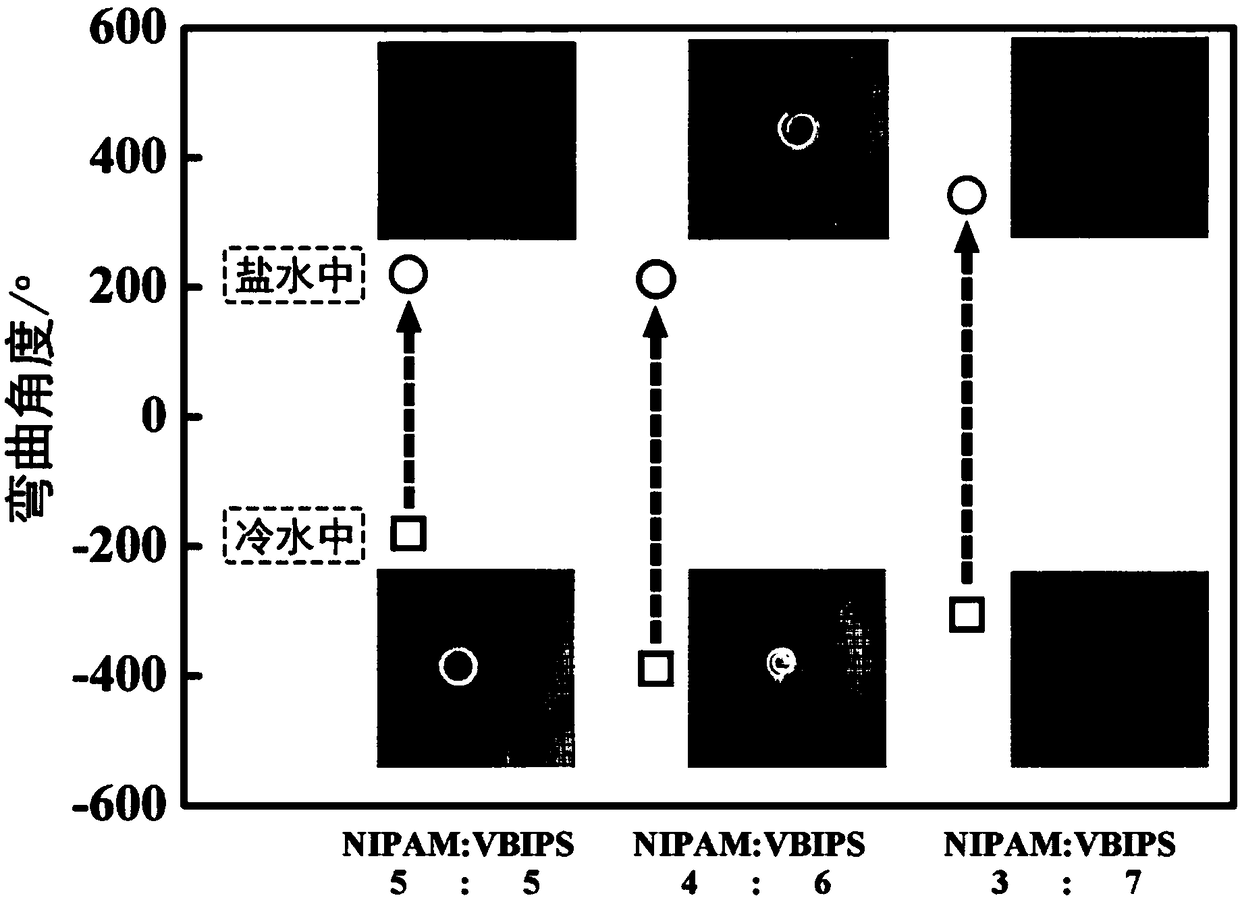

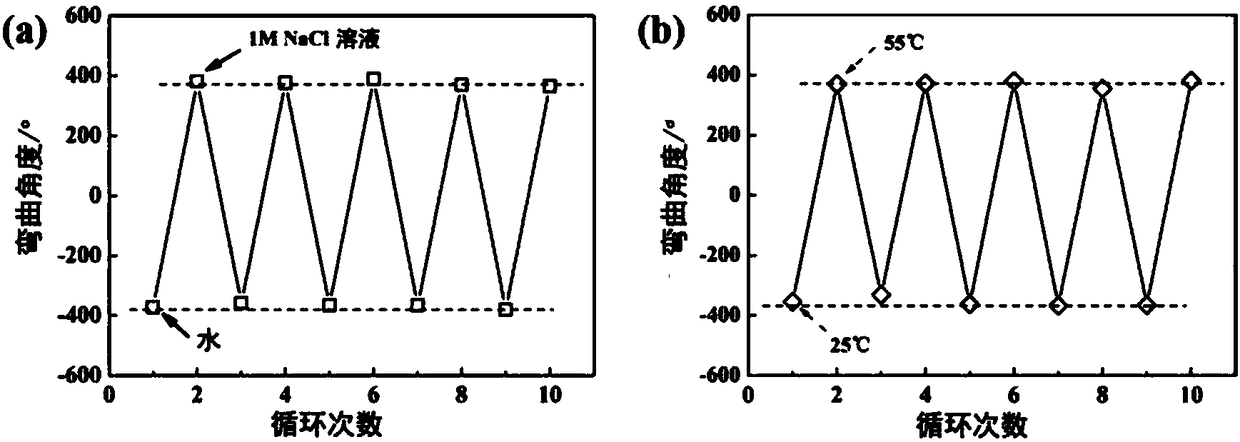

[0049] Dissolve 0.3g functional monomer N-isopropylacrylamide (NIPAM) and 0.3g formula II-12 monomer n=3 (VBIPS) in 2.0g deionized water, then add 0.002g photoinitiator 2-hydroxy -4'-(2-hydroxyethoxy)-2-methylpropiophenone (photoinitiator 2959), 0.002g crosslinker N,N-methylene bisacrylamide (MBAA), 0.006g free radical initiator Agent ammonium persulfate (APS) and 30 μL catalyst N,N,N′,N′-tetramethylethylenediamine (TEMED). After fully dissolving, nitrogen gas was blown for 20 minutes to obtain the reaction solution, and then the reaction solution was injected into the abrasive tool with a syringe. The abrasive tool was composed of two layers of quartz glass and a PTFE separator with a thickness of 0.5 mm. The reaction system was exposed to UV light with a wavelength of 365 nm for 2 hours at room temperature to obtain a polyNIPAM / VBIPS bilayer hydrogel. Soak the prepared polyNIPAM / VBIPS double-layer hydrogel in cold water at 25°C for 400s, and the double-layer hydrogel quickl...

Embodiment 2

[0052] Dissolve 0.24g functional monomer N-isopropylacrylamide (NIPAM) and 0.36g VBIPS in 2.0g deionized water, then add 0.0026g photoinitiator 2959, 0.002g crosslinking agent (MBAA), 0.0048g free base initiator (APS) and 25 μL catalyst (TEMED). After fully dissolving, nitrogen gas was blown for 20 minutes, and then the reaction liquid was injected into the abrasive tool with a syringe. The abrasive tool was composed of two layers of quartz glass and a 0.5mm thick PTFE separator. The reaction system was exposed to UV light with a wavelength of 365 nm for 2 hours at room temperature to obtain a polyNIPAM / VBIPS bilayer hydrogel. Soak the prepared polyNIPAM / VBIPS double-layer hydrogel in cold water at 25°C for 400s, and the double-layer hydrogel quickly bends toward the side of the polyVBIPS layer; turn the double-layer hydrogel from cold water to soak in 1mol / L After being immersed in NaCl solution for 400s, the double-layer hydrogel turned to the side of the polyNIPAM layer an...

Embodiment 3

[0055] Dissolve 0.18g functional monomer N-isopropylacrylamide (NIPAM) and 0.42g VBIPS in 2.0g deionized water, then add 0.003g photoinitiator 2959, 0.002g crosslinking agent (MBAA), 0.0036g free base initiator (APS) and 20 μL catalyst (TEMED). After fully dissolving, nitrogen gas was blown for 20 minutes, and then the reaction liquid was injected into the abrasive tool with a syringe. The abrasive tool was composed of two layers of quartz glass and a 0.5mm thick PTFE separator. The reaction system was exposed to UV light with a wavelength of 365 nm for 2 hours at room temperature to obtain a polyNIPAM / VBIPS bilayer hydrogel. Soak the prepared polyNIPAM / VBIPS double-layer hydrogel in cold water at 25°C for 400s, and the double-layer hydrogel quickly bends toward the side of the polyVBIPS layer; turn the double-layer hydrogel from cold water to soak in 1mol / L After being immersed in NaCl solution for 400s, the double-layer hydrogel turned to the side of the polyNIPAM layer and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com