A kind of high-strength silicon calcium phosphate bioceramic material and preparation method thereof

A bioceramic material, silicon calcium phosphate technology, applied in tissue regeneration, prosthesis, medical science, etc., can solve the problems of excellent mechanical properties and biological activity that are difficult to obtain by the preparation method, so as to solve the problem of difficult sintering and improve biological Activity and degradability, the effect of excellent biological performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention provides a kind of preparation method of high-strength silicon calcium phosphate bioceramic material in the first aspect, described method comprises the following steps:

[0032] (1) uniformly mixing zinc oxide powder, calcium silicon phosphate powder and binder to obtain a mixture, and then molding the mixture to obtain a ceramic green body; and

[0033] (2) Sintering the ceramic green body obtained in step (1) (normal pressure sintering) to prepare a high-strength calcium silicon phosphate bioceramic material.

[0034] In the present invention, the normal pressure sintering process is adopted, which is simple and controllable. Biologically safe and non-toxic zinc oxide is used as the sintering aid, and silicon calcium phosphate is the main phase. Press sintering to prepare high-strength silicon calcium phosphate bioceramic materials; the present invention reduces the sintering temperature by adopting zinc oxide as a sintering aid, and through low...

Embodiment 1

[0052] First weigh 0.5g of hexagonal zinc oxide powder and 49.5g of silicon calcium phosphate powder, add 50g of deionized water, add 5.0g of polyvinyl alcohol aqueous solution with a solution concentration of 10wt%, and planetary ball mill for 3 hours to obtain a uniformly dispersed mixture , and then dried at 60°C for 12 hours, sieved to obtain a mixture with uniform particle size; then the obtained mixture was sequentially subjected to dry pressing (dry pressing molding pressure 50MPa, holding time 5min) and cold isostatic pressing (The pressure of cold isostatic pressing is 200MPa, and the pressure holding time is 5min). The length, width and height are 3×4×40mm. 2°C / min heating rate to 500°C for 2 hours to remove the binder, and then 2°C / min heating rate to 1300°C (final sintering temperature) for 2 hours to obtain a zinc oxide addition of 1wt% High-strength calcium silicon phosphate bioceramic material.

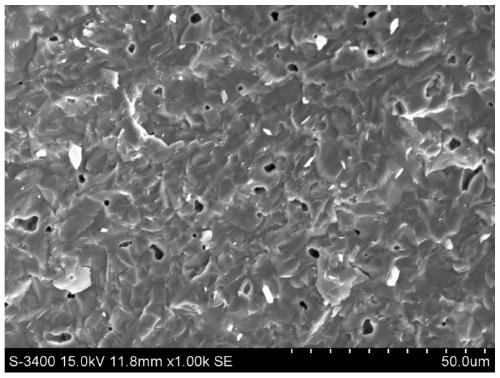

[0053] The high-strength calcium silicophosphate bioceramic mater...

Embodiment 2

[0056] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0057] The consumption of hexagonal zinc oxide powder is 1.5g, and the consumption of calcium silicon phosphate powder is 48.5g, and the high-strength calcium silicon phosphate bioceramic material that the addition of zinc oxide is obtained is 3wt%; Other difference is as shown in table 1 .

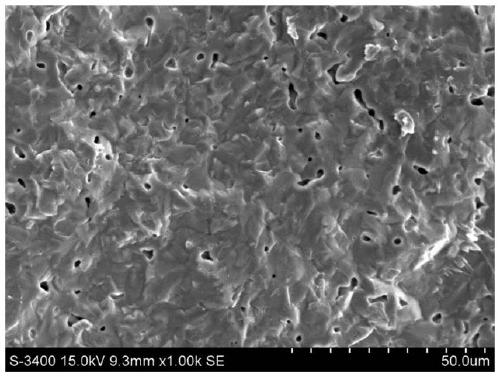

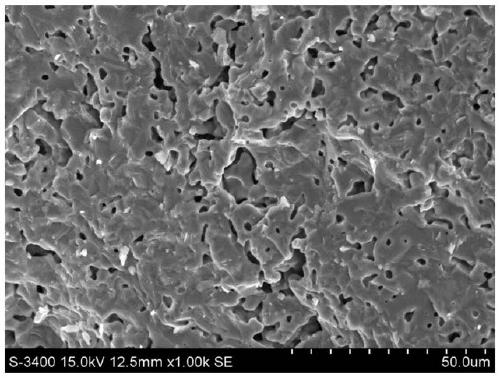

[0058] The cross-sectional morphology of the high-strength calcium silicophosphate bioceramic material prepared in this embodiment is as follows: figure 2 shown. comprehensive figure 2 As can be seen from Table 1, with the increase of zinc oxide addition, the densification degree of the high-strength calcium silicophosphate bioceramic material increases, and the content of zehnite and residual zinc oxide both increase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com