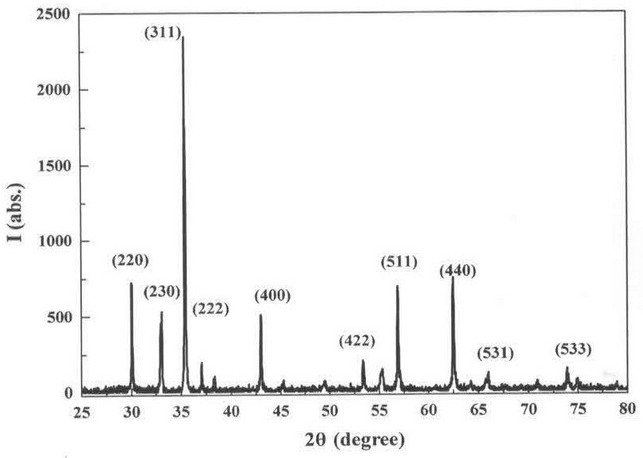

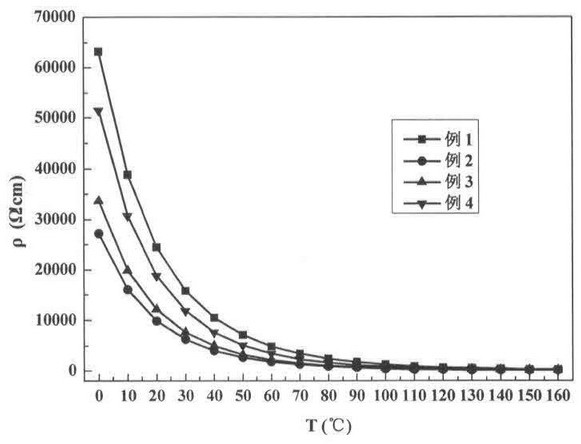

A niobium-doped manganese-nickel-based negative temperature coefficient thermistor and its preparation method

A technology of negative temperature coefficient and thermistor, applied in the direction of resistors with negative temperature coefficient, resistors, non-adjustable metal resistors, etc. Uniformity, limited uniformity and stability and other issues, to achieve the effect of stable structure, low sintering temperature and simple material composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation by solid phase method:

[0024] a. Press the raw material according to Mn 2.25 Ni 0.74 Nb 0.01 O formula ingredients, where x = 0.01, weighed MnO 2 19.5g, Ni 2 o 3 6.12g and Nb 2 o 5 0.13g, put it into a 500mL polytetrafluoroethylene ball mill jar, then add 50 agate balls with a diameter of 50mm into the ball mill jar, place the ball mill jar on a planetary ball mill, and grind for 8 hours;

[0025] b. Dry the ground product obtained in step a in an oven at a temperature of 100°C for 24 hours, take it out, place it in an agate grinder, and grind it manually until it becomes powdery;

[0026] c. Put the powder obtained in step b in an alumina crucible pre-fired at a temperature of 1200°C, pre-fire at a temperature of 800°C for 1 hour, and then hand-grind for 2 hours after sintering to obtain a heat-sensitive powder material ;

[0027] d. Press the powder obtained in step c into a green body, and sinter at a temperature of 1200° C. for 2 hours to obt...

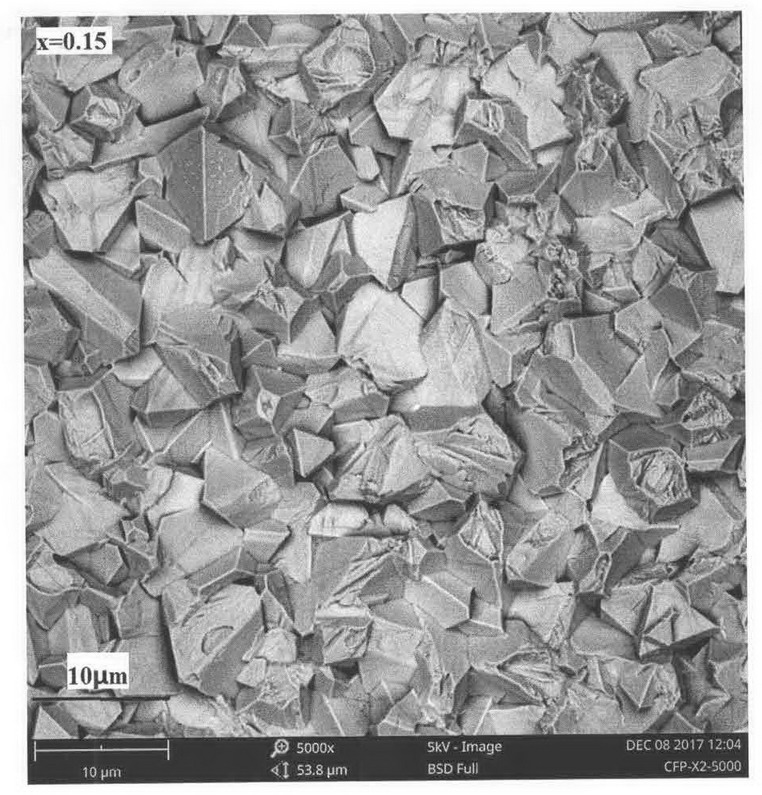

Embodiment 2

[0031] Preparation by solid phase method:

[0032] a. Press the raw material according to Mn 2.25 Ni 0.6 Nb 0.15 O formula ingredients, wherein x=0.15-0.35, weigh MnO 2 35g, Ni 2 o 3 20g and Nb 2 o 5 2.3g, put it into a 500mL polytetrafluoroethylene ball mill jar, then add 150 agate balls with a diameter of 50mm into the ball mill jar, place the ball mill jar on a planetary ball mill, and grind for 8 hours;

[0033] b. Dry the ground product obtained in step a in an oven at a temperature of 100°C for 24 hours, take it out, place it in an agate grinder, and grind it manually until it becomes powdery;

[0034] c. Put the powder obtained in step b in an alumina crucible pre-fired at a temperature of 1200°C, pre-fire at a temperature of 800°C for 1 hour, and then hand-grind for 2 hours after sintering to obtain a heat-sensitive powder material ;

[0035] d. Press the powder obtained in step c into a green body, and sinter at a temperature of 1200° C. for 2 hours to obtai...

Embodiment 3

[0039] Preparation by solid phase method:

[0040] a. Press the raw material according to Mn 2.25 Ni 0.5 Nb 0.25 O formula ingredient, wherein x=0.25, weighs MnSO 4 40g, Ni 2 (SO 4 ) 3 5.5g and Nb 2 (SO 4 ) 5 4.0g, put into a 500mL polytetrafluoroethylene ball mill jar, then add 150 agate balls with a diameter of 50mm in the ball mill jar, place the ball mill jar on a planetary ball mill, and grind for 8 hours;

[0041] b. Dry the ground product obtained in step a in an oven at a temperature of 100°C for 24 hours, take it out, place it in an agate grinder, and grind it manually until it becomes powdery;

[0042] c. Put the powder obtained in step b in an alumina crucible pre-fired at a temperature of 1200°C, pre-fire at a temperature of 800°C for 1 hour, and then hand-grind for 2 hours after sintering to obtain a heat-sensitive powder material ;

[0043] d. Press the powder obtained in step c into a green body, and sinter at a temperature of 1200° C. for 2 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com