Lithium ion battery core and preparation method thereof, and lithium ion battery

A technology of lithium-ion batteries and batteries, which is applied in the manufacture of electrolyte batteries, secondary batteries, battery pack components, etc. It can solve problems such as poor bonding and diaphragm clogging, and achieve improved bonding and enhanced bonding effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

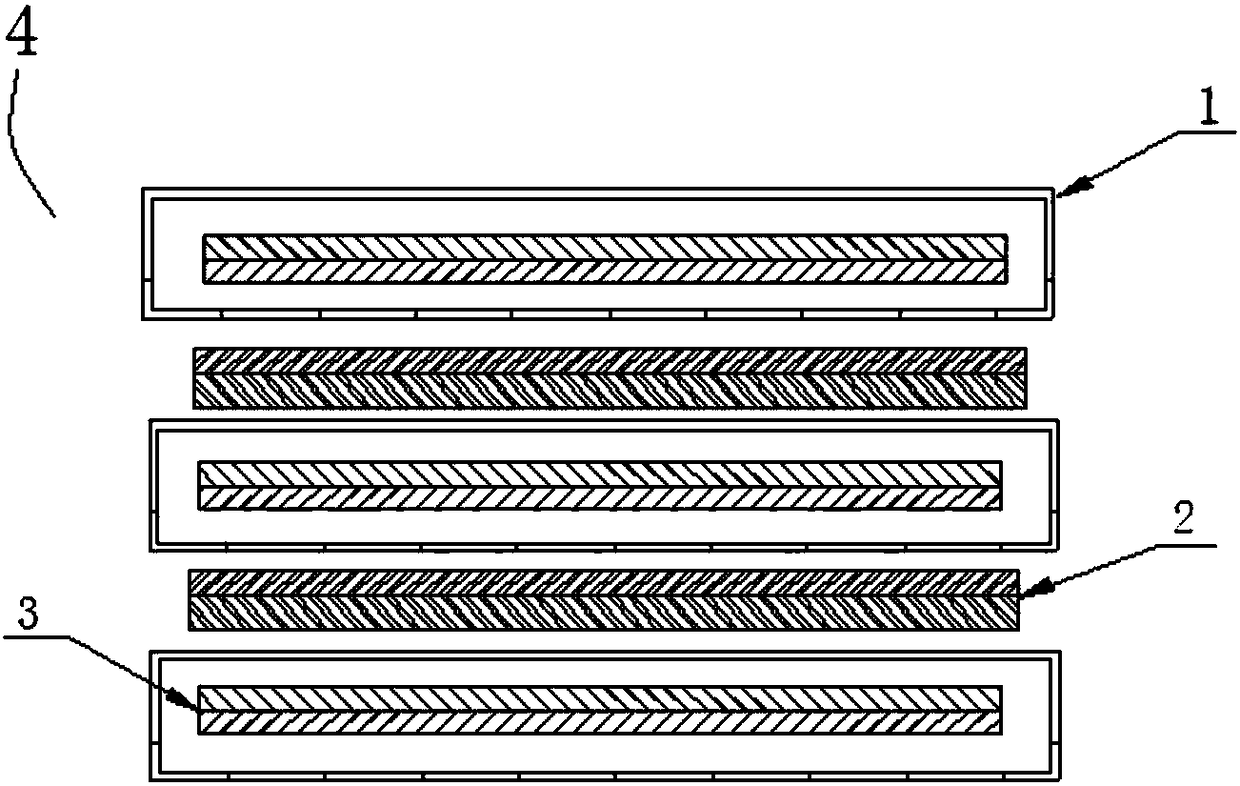

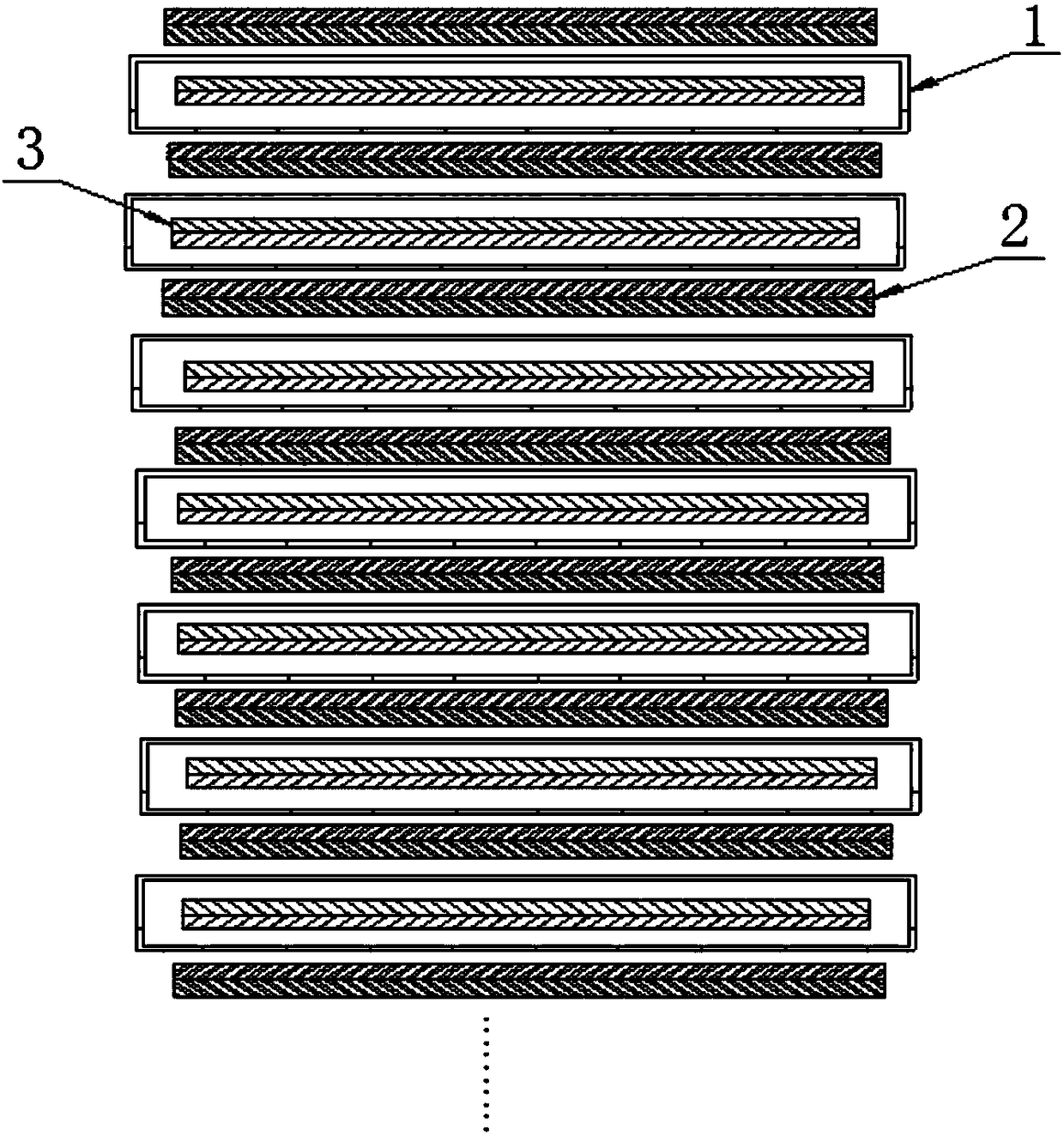

[0030] The lithium-ion battery cell of the present embodiment has a structural schematic diagram as Figure 1 ~ Figure 3 As shown, it includes a first thin cell unit 4 and a second thin cell unit 5 that are stacked in sequence. The first thin cell unit 4 includes a separator bag 1 with a positive electrode sheet 3 and a negative electrode sheet 2 stacked on top of each other. The number of bags 1 is 3, the number of negative electrode sheets is 2, the structure of the second thin cell unit 5 can refer to the first thin cell unit 4, the difference is that the number of diaphragm bags 1 is 2, and the number of negative electrode sheets 2 Quantity is 3 pcs. The membrane bag 1 is made of a membrane including a polyolefin film and polyvinylidene fluoride adhesive layers provided on both surfaces of the polyolefin film. The thickness of the polyolefin film was 20 μm, and the thickness of the polyvinylidene fluoride adhesive layer was 1 μm. The lithium-ion battery cell is specifica...

Embodiment 2

[0035] The preparation method of the lithium-ion battery cell of the present embodiment, such as Figure 1 ~ Figure 3 shown, including the following steps:

[0036] 1) Refer to Example 1 to make the first thin cell unit and the second thin cell unit. The hot pressing conditions of the first thin cell unit and the second thin cell unit are the same, both at 90°C and 0.2MPa Hold down for 20s;

[0037] 2) After the first thin cell unit and the second thin cell unit are stacked in sequence, they are kept at 90° C. and 0.3 MPa for 60 seconds to obtain the lithium-ion battery cell.

[0038] In step 1), the diaphragm used in the diaphragm bag includes a polyolefin film and polyvinylidene fluoride adhesive layers arranged on both sides of the polyolefin film. The thickness of the polyolefin film was 20 μm, and the thickness of the polyvinylidene fluoride adhesive layer was 2 μm.

Embodiment 3

[0040] The preparation method of the lithium-ion battery cell of the present embodiment, such as Figure 1 ~ Figure 3 shown, including the following steps:

[0041] 1) Refer to Example 1 to make the first thin cell unit and the second thin cell unit, the hot pressing conditions of the first thin cell unit and the second thin cell unit are the same, both at 85°C and 0.1MPa Hold down for 10s;

[0042]2) After stacking the first thin cell unit and the second thin cell unit in sequence, they are kept at 90° C. and 0.3 MPa for 20 seconds to obtain the lithium-ion battery cell.

[0043] In step 1), the diaphragm used in the diaphragm bag includes a polyolefin film, and one side surface of the polyolefin film is provided with a ceramic particle layer and a polymethyl methacrylate adhesive layer sequentially from the inside to the outside, and the other side surface is It is also coated with a polymethyl methacrylate adhesive layer. The thickness of the polyolefin film is 20 μm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com