OLED display panel and manufacturing method thereof

A technology for display panels and manufacturing methods, applied in chemical instruments and methods, manufacturing tools, lamination auxiliary operations, etc., can solve the problems of expensive equipment, affecting the process, and burnt electrodes 230, so as to reduce the generation of particulate matter and protect burns Damage, the effect of ensuring the encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0079] see Figure 13 , the invention provides a method for manufacturing an OLED display panel, comprising the following steps:

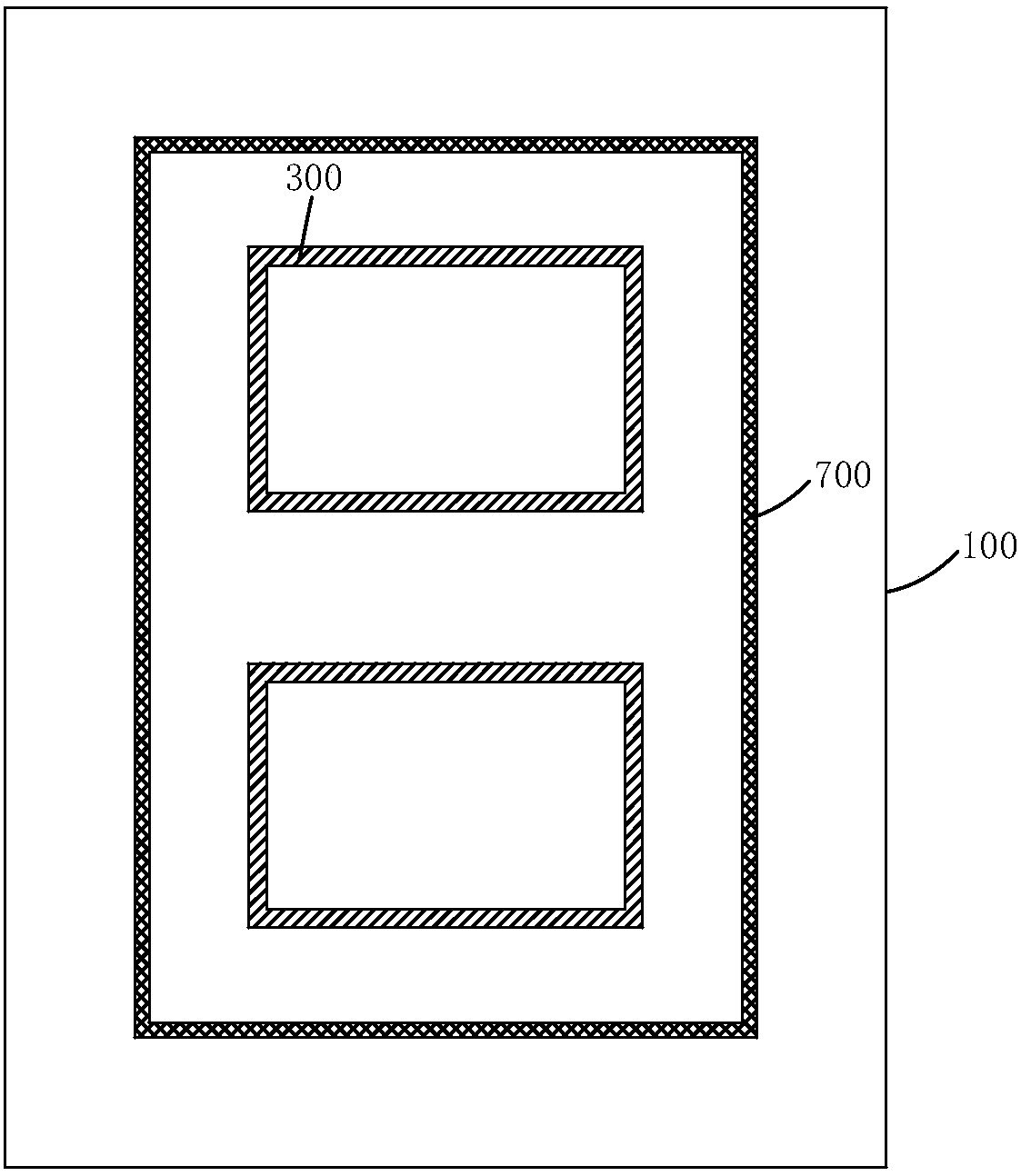

[0080] Step 1, such as Figure 14 to Figure 17 As shown, a package cover 10 is provided, and the package cover 10 includes a cover body 11 and a first light-shielding film 51 and a second light-shielding film 52 arranged on the cover body 11; One or more sealant coating areas 40, the sealant coating area 40 includes a thick sealant area 43 and a first thin sealant area 41 and a second thin sealant area 42 located on both sides of the thick sealant area 43 ; The first light-shielding film 51 and the second light-shielding film 52 are respectively arranged on both sides of the frame rubber thick area 43;

[0081] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com