Grooved gate short circuit anode SOI LIGBT

A technology of slot grid and anode, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of large conduction voltage drop, low anode hole injection efficiency, and influence on the uniformity of device current distribution, etc., to reduce the conduction voltage The effect of reducing, eliminating the voltage foldback phenomenon, and eliminating the voltage foldback effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

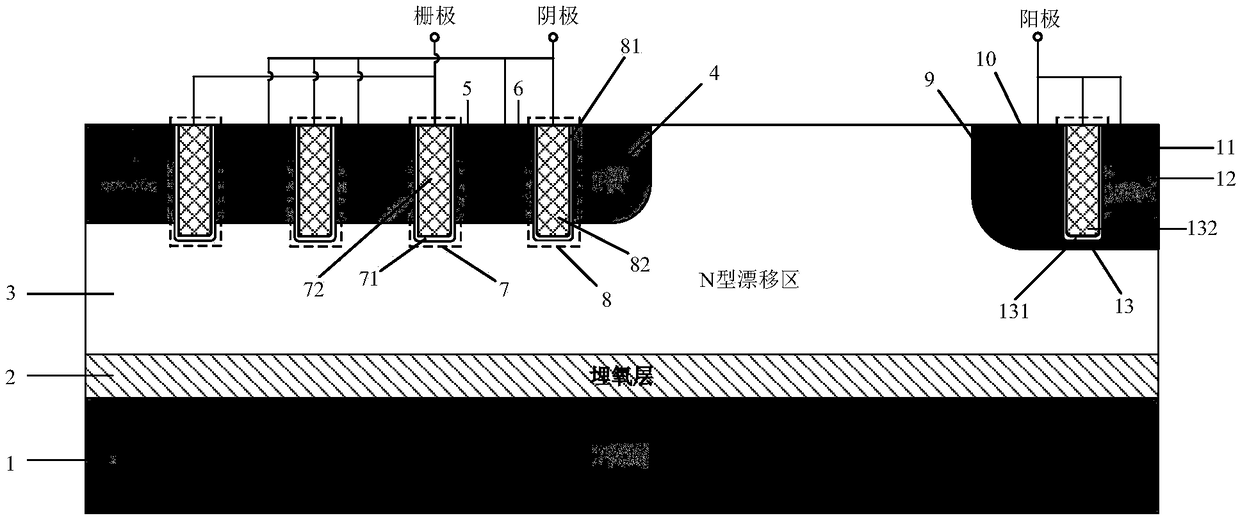

[0019] Such as figure 1 As shown, the SOI LIGBT of this example includes a P substrate 1, a buried oxide layer 2, and a top semiconductor layer stacked sequentially from bottom to top; the top semiconductor layer has an N-type drift region 3, and an N-type drift region 3 One side has a P well region 4, and the other side is an anode structure; the upper surface of the P well region 4 has an N+ cathode region 5 and a P+ body contact region 6, and the lead end of the P+ body contact region 6 is a cathode; In the well region 4, there are groove grids 7 and cathode grooves 8 that penetrate the P well region 4 from the surface and extend from the bottom to the N-type semiconductor drift region 3, and the groove grids 7 are in contact with the N+ cathode region 5, and the cathode grooves 8 In contact with the P+ body contact region 6, the slot grid 7 and the cathode slot 8 respectively have a first insulating dielectric layer 71 and a second insulating dielectric layer 81 located on...

Embodiment 2

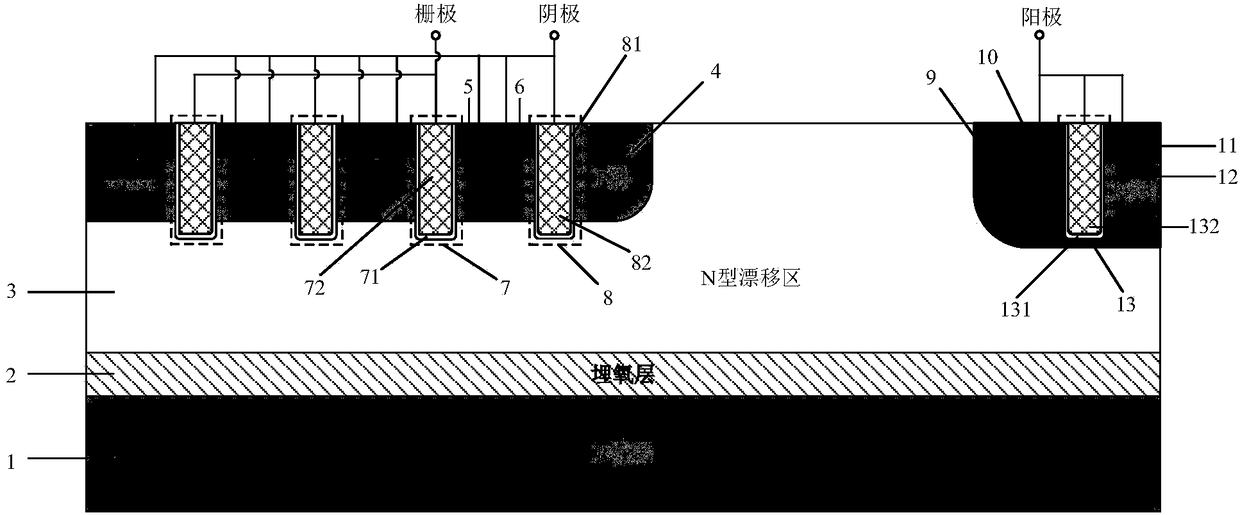

[0023] Such as figure 2 As shown, compared with Embodiment 1, there are multiple slot gates 7 and cathode slots 8 in this example, which are alternately arranged along the lateral direction of the device. Multiple trench gates increase the channel density of the device and reduce the conduction voltage drop.

Embodiment 3

[0025] Such as image 3 As shown, compared with Embodiment 2, the N+ cathode region 5 is connected to the cathode in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com