Preparation method of oligosaccharide for promoting proliferation of intestinal probiotics

A technology for intestinal probiotics and oligosaccharides, which is applied in the preparation of oligosaccharides and sugar derivatives, chemical instruments and methods, etc., to achieve the effects of simple production process, expanding the number of users and application fields, and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

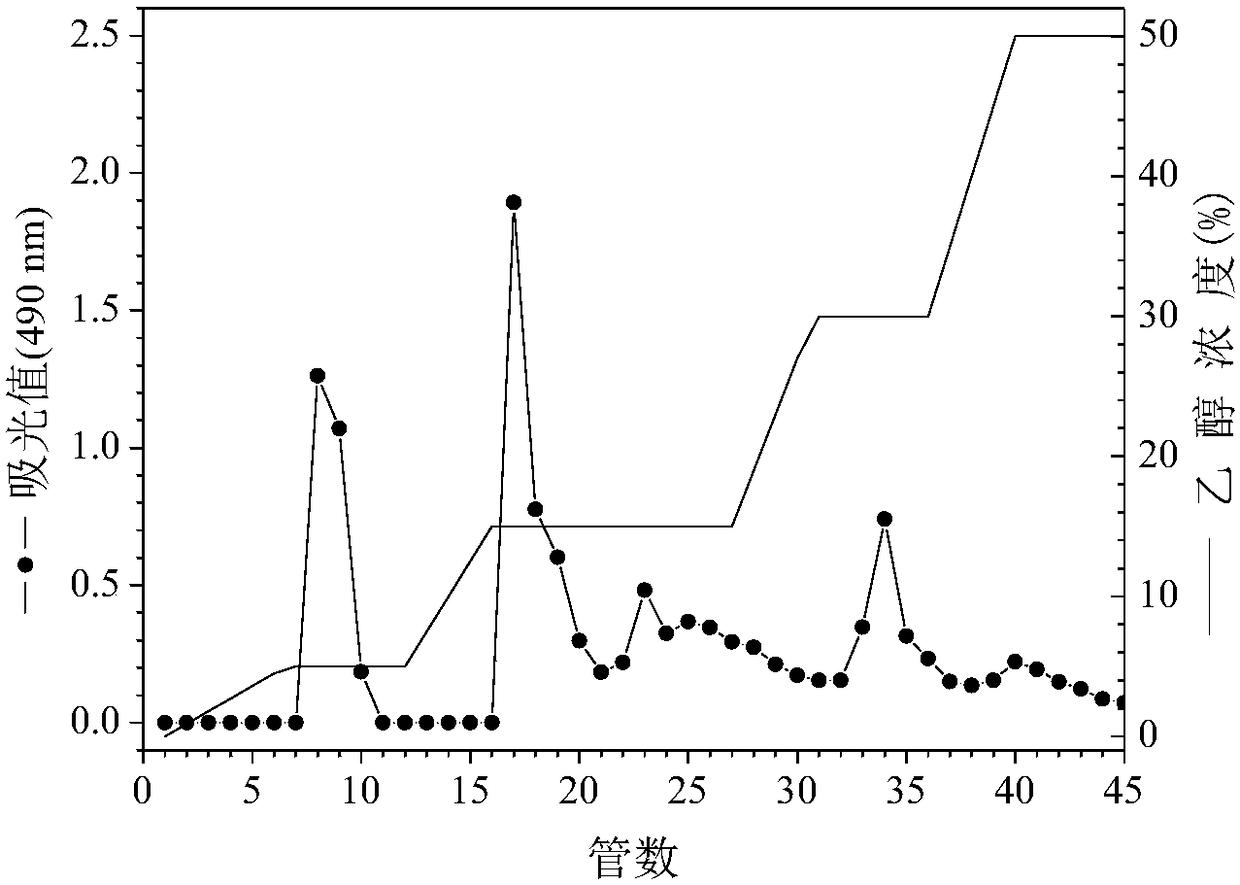

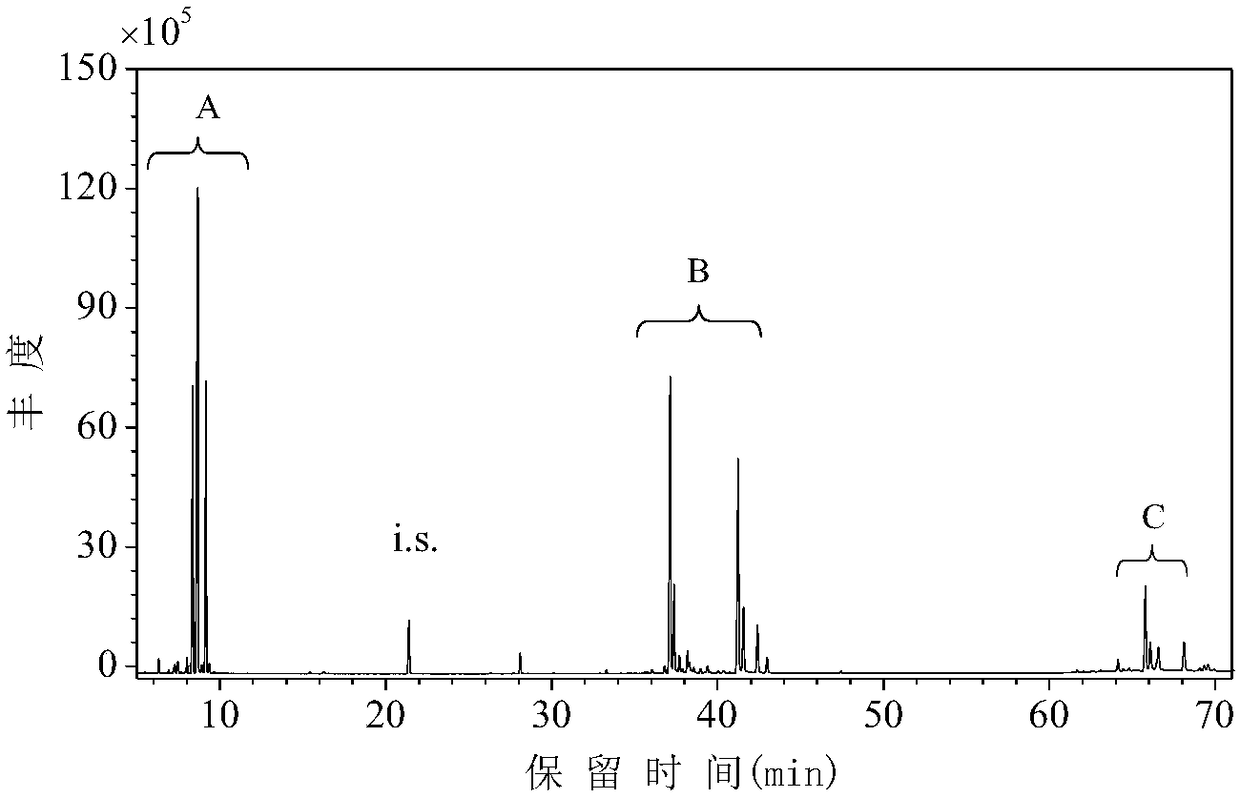

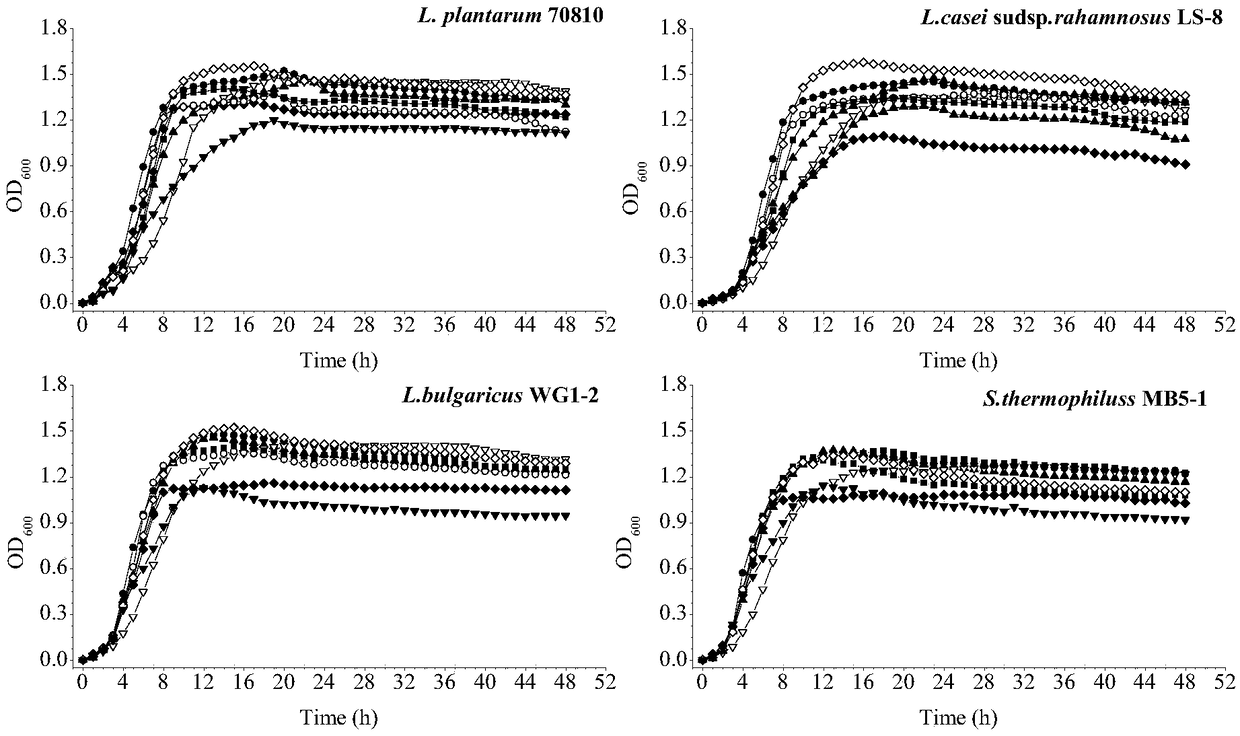

[0043] Put lactose and melibiose receptors in a screw bottle at a ratio of 1:2, add 50mmol / L phosphate buffer solution with pH 6.5 to adjust the total sugar concentration to 40%, and process under high pressure (121°C, 103Kpa, 20min) , let it completely dissolve, cool naturally to the reaction temperature of 40°C, and keep warm in a water bath for 30 minutes; weigh an appropriate amount of β-galactosidase and add it to the above reaction system to make it reach a final concentration of (10U / mL) and place it on a constant temperature water bath shaker ( 150r / min) for the reaction; after 14 hours of reaction, the boiling water bath was used to inactivate the enzyme for 5 minutes to terminate the reaction; the above reaction product was classified and purified by activated carbon-diatomaceous earth adsorption chromatography to remove monosaccharides and disaccharides, and the purified product was diluted After freeze-drying, a novel functional oligosaccharide is obtained.

[0044...

Embodiment 2

[0048] Put lactose and cellobiose receptors in a screw bottle at a ratio of 1:3, add a 50mmol / L phosphate buffer solution with pH 7.0 to adjust the total sugar concentration to 50%, and process under high pressure (121°C, 103Kpa, 20min) , to make it completely dissolved, then cool naturally to the reaction temperature of 44°C, and keep it warm in a water bath for 30 minutes; weigh an appropriate amount of β-galactosidase and add it to the above reaction system to make it reach a final concentration of (15U / mL) and place it in a constant temperature water bath shaker ( 200r / min) for the reaction; after 12 hours of reaction, the boiling water bath was used to inactivate the enzyme for 5 minutes to terminate the reaction; the above reaction product was classified and purified by activated carbon-diatomaceous earth adsorption chromatography to remove monosaccharides and disaccharides, and the purified product was diluted After freeze-drying, a novel functional oligosaccharide is ob...

Embodiment 3

[0053] Put the lactose and trehalose receptors in a screw bottle at a ratio of 1:4, add a 50mmol / L phosphate buffer solution with pH 7.5 to adjust the total sugar concentration to 60%, and perform high pressure treatment (121°C, 103Kpa, 20min), Let it completely dissolve and cool naturally to the reaction temperature of 42°C, and keep it warm in a water bath for 30 minutes; weigh an appropriate amount of β-galactosidase and add it to the above reaction system to make it reach a final concentration of (20U / mL) and place it in a constant temperature water bath shaker (250r After 10 hours of reaction, the boiling water bath was used to kill the enzyme for 5 minutes to terminate the reaction; the above reaction product was classified and purified by activated carbon-diatomaceous earth adsorption chromatography to remove monosaccharides and disaccharides, and the purified product was diluted Freeze-dry to obtain novel functional oligosaccharides.

[0054] The yield of oligosacchari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com