A carbazole-based conjugated microporous polymer microsphere wrapped with quantum dots and its preparation method, a quantum dot film and its application

A technology of conjugated micropores and quantum dots, applied in chemical instruments and methods, instruments, luminescent materials, etc., can solve the problems of low blue light utilization efficiency, low blue light purity and low utilization efficiency of quantum dots, and reduce the actual usage. , Excellent optical performance, the effect of improving utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

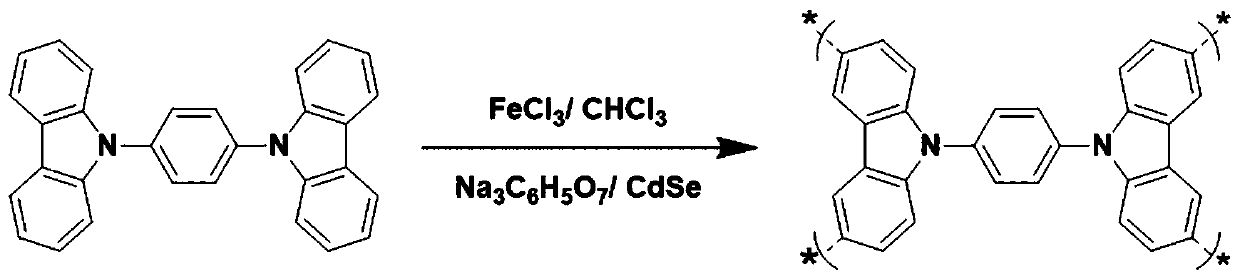

[0053] The preparation method of the carbazole-based conjugated microporous polymer microspheres wrapped with quantum dots provided by the present invention comprises the following steps:

[0054] (1) Preparation of carbazole-based conjugated microporous polymer microspheres coated with quantum dots Add appropriate amount of ferric chloride powder to the ethanol solution dissolved with sodium citrate and cadmium selenide quantum dots, and then add Chloroform solution dissolved with carbazole-based monomer, last at room temperature for 24 hours;

[0055] (2) After filtering, washing and Soxhlet extraction, the carbazole-based conjugated microporous polymer microspheres wrapped with quantum dots are obtained.

[0056] The present invention also provides a preparation method of a quantum dot film: stirring the carbazole-based conjugated microporous polymer microspheres wrapped with the quantum dots and the acrylate UV curing glue to evenly form the coating solution of the quantum...

Embodiment 1

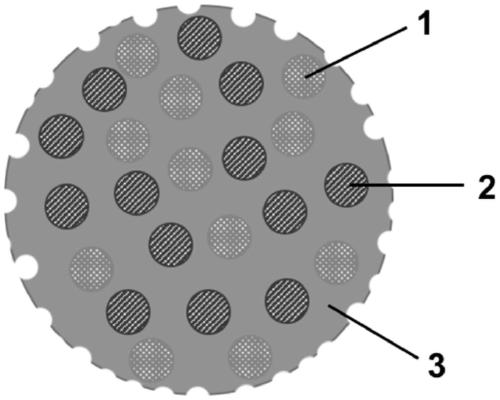

[0087] The invention provides a carbazole-based conjugated microporous polymer microsphere wrapped with quantum dots, and the quantum dots are distributed in the carbazole-based conjugated microporous polymer microsphere.

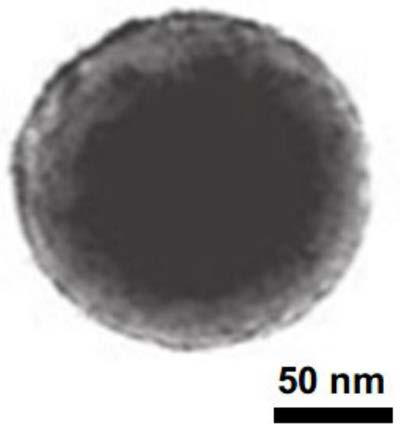

[0088] After replacing the nitrogen gas in the 250mL three-neck flask, quickly weigh and add 2g FeCl 3 and 30 mL of chloroform. Then add 20mL ethanol solution with 0.5g red cadmium selenide, 0.5g green cadmium selenide and 1g sodium citrate, and slowly add 50mL chloroform with 1g 1,4-bis(9-carbazole)benzene dropwise with a syringe solution, start stirring. React at room temperature for 24 hours, then add 300 mL of methanol and stir for 1 hour, filter with suction and rinse with methanol, concentrated hydrochloric acid and deionized water once, and finally extract with methanol and tetrahydrofuran for 24 hours to obtain a crude product. Finally, 1.97 g of yellow powder was obtained by vacuum drying at 60° C. for 12 hours, which were carbazole-based conjuga...

Embodiment 2

[0091] The carbazole-based conjugated microporous polymer microspheres wrapped with quantum dots as provided in Example 1.

[0092] After replacing the nitrogen gas in the 250mL three-neck flask, quickly weigh and add 2g FeCl 3 and 30 mL of chloroform. Then add 20mL ethanol solution containing 0.5g red cadmium selenide, 0.5g green cadmium selenide and 0.1g sodium citrate, and slowly add 50mL of 1g 1,4-bis(9-carbazole)benzene Chloroform solution, start stirring. React at room temperature for 24 hours, then add 300 mL of methanol and stir for 1 hour, filter with suction and rinse with methanol, concentrated hydrochloric acid and deionized water once, and finally extract with methanol and tetrahydrofuran for 24 hours to obtain a crude product. Finally, 1.67 g of yellow powder was obtained by vacuum drying at 60° C. for 12 hours, which were carbazole-based conjugated microporous polymer microspheres wrapped with quantum dots.

[0093] The performance test results of the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com