PA6 composite material and preparation method thereof

A composite material and mixture technology, applied in the field of PA6 composite material and its preparation, can solve the problems of low extrusion production capacity, poor mechanical properties, difficult processing and molding, etc., and achieve the effects of excellent mechanical properties and excellent thermal conductivity.

Active Publication Date: 2018-08-10

东莞市银禧光电材料科技股份有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For the thermally conductive PA6 currently on the market, thermally conductive fillers generally use aluminum oxide (Al2O3), boron nitride, aluminum nitride (AlN), magnesium oxide (MgO), silicon carbide whiskers, etc. Low coefficient, difficult processing and poor mechanical properties, high industrial cost, low extrusion production capacity and other problems, it requires very high fillers to meet the flame retardant V0 requirements, or additional bromine antimony or phosphorus nitrogen flame retardants The material meets V0, but bromine-antimony flame retardants will affect the electrical properties of the material. Although phosphorus-nitrogen flame retardants do not affect the electrical properties, they will precipitate under high temperature and high humidity conditions, affecting the luminous efficiency and appearance of the LED

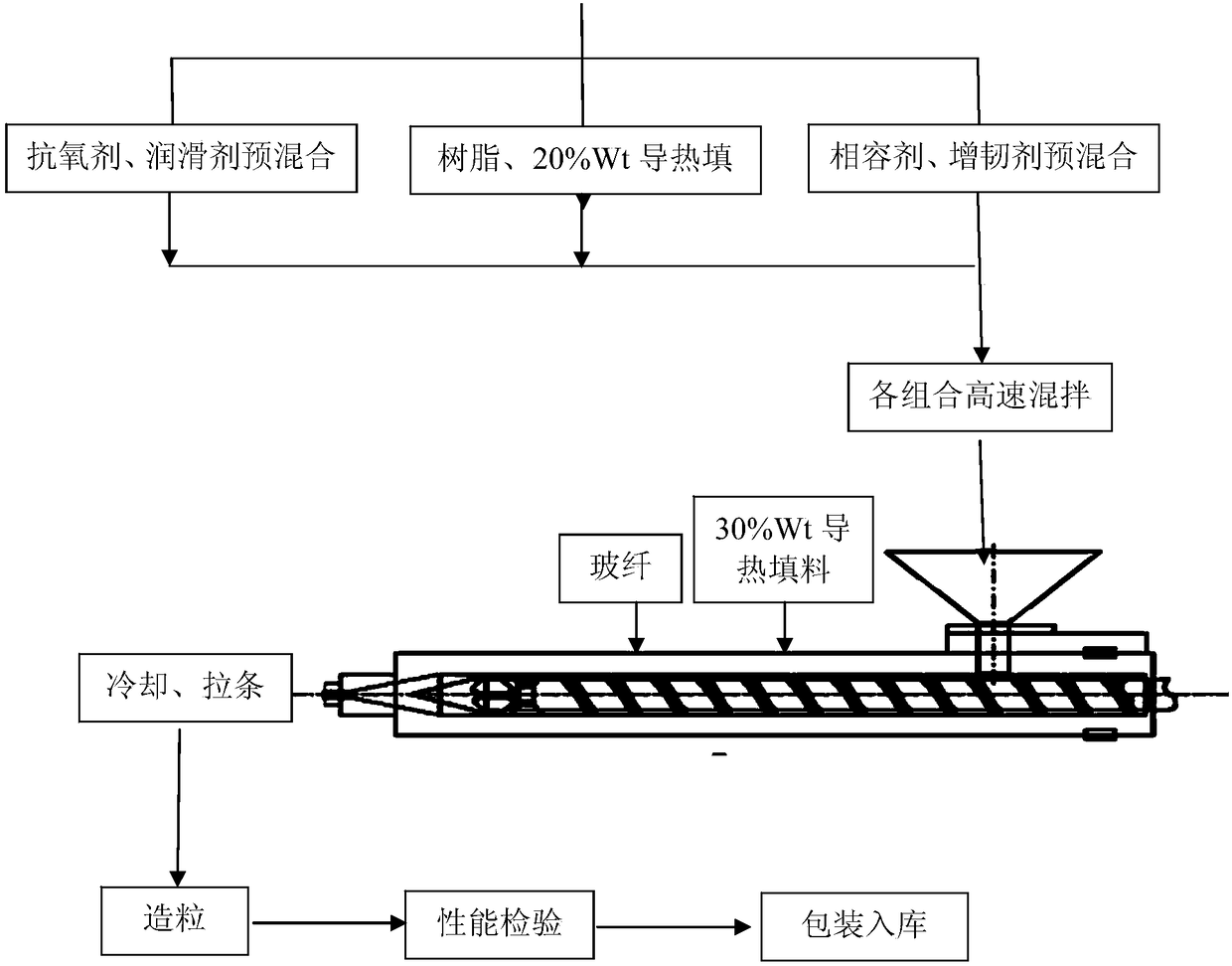

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-8

[0060] Examples 1-8 provide PA6 composite materials with different raw material ratios, and the mass fractions of the components in each example are shown in Table 2.

[0061] Table 2

[0062]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a PA6 composite material and a preparation method thereof. The PA6 composite material is prepared from the following ingredients in parts by mass: 33 to 37 percent of PA6 resin,8 to 13 percent of alkali-free glass fiber, 0 to 50 percent of magnesium oxide, 0 to 50 percent of magnesium hydrate and 0 to 5 percent of auxiliary agents, wherein the sum of the mass of the magnesium oxide and the magnesium hydrate does not exceed 60 percent of the total mass of the composite material. The composite material has excellent heat conduction performance, and simultaneously has excellent mechanical performance; the halogen-free flame-retardant effect can be achieved. The process of the preparation method is simple; the preparation method is suitable for industrial production.

Description

technical field [0001] The invention belongs to the field of composite materials, and relates to a PA6 composite material and a preparation method thereof. Background technique [0002] In recent years, due to the advancement of plastic modification technology, some plastic raw material factories have developed thermally conductive plastics with high thermal conductivity, and their thermal conductivity can reach 1w / mk to 30w / mk. Thereby opening up the way for plastic LED light cups. Like traditional light sources, LEDs also generate heat during operation, and their luminous efficiency is greatly affected by the outside world and itself. In fact, the heat generated on the chip cannot be removed in time. It restricts the design of many new products in the engineering field. Compared with traditional aluminum materials, polymer heat-conducting composite materials have the advantages of high insulation, corrosion resistance, light weight, high degree of machinability and design...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L77/02C08L51/06C08L83/04C08K13/04C08K7/14C08K3/22

CPCC08K3/22C08K7/14C08K2003/222C08K2003/2224C08L77/02C08L2201/02C08L2201/22C08L2205/03C08L51/06C08L83/04C08K13/04

Inventor 贡新浩李小辉傅轶

Owner 东莞市银禧光电材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com