High-efficiency filter apparatus and method for mixture

A filter device and high-efficiency filtration technology, which is applied in the field of analytical chemistry, can solve problems such as insufficient filtration separation, low filtration efficiency, and influence on experimental accuracy, and achieve the effects of fast filtration speed, high stability, and large rinsing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

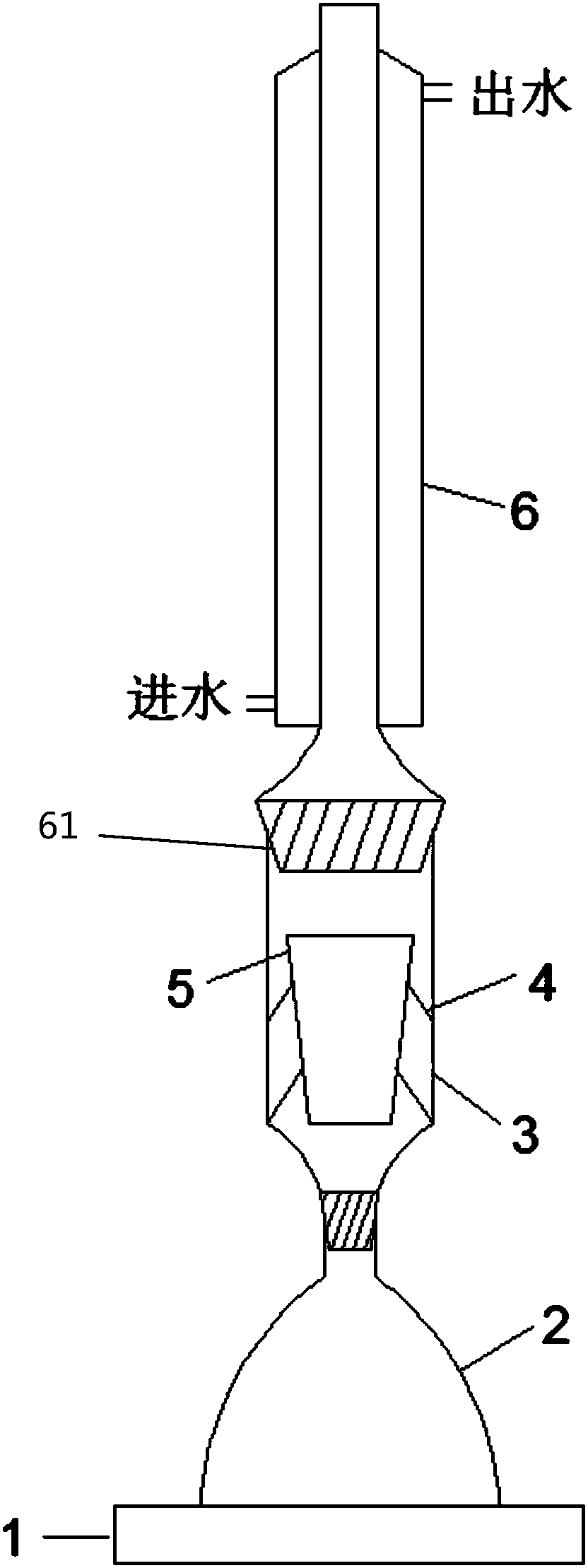

[0053] In this embodiment, the mixture high-efficiency filtration device and filtration method described in the present invention are used to filter 1 g of rubber powder modified asphalt

[0054] Step 1: Put 1g of rubber powder modified asphalt in filter cartridge 5, and put 60ml of trichlorethylene into container 2;

[0055] Step 2: Turn on the temperature-adjustable electric furnace 1 until the temperature reaches the boiling point of trichlorethylene, after the trichlorethylene in the container 2 is vaporized, enter the inner tube of the condenser 6 through the extractor 3;

[0056] Step 3: The vaporized trichlorethylene is condensed into a liquid in the inner tube of the condensation pipe 6, and then dripped into the filter cartridge 5 in the extractor 3, and the rubber powder modified asphalt in the filter cartridge 5 is leached and dissolved There is the trichlorethylene of the soluble component in the rubber powder modified asphalt dripping in the container 2 by filter ...

Embodiment 2

[0060] In this embodiment, 1 g of rubber powder modified asphalt is filtered by using the mixture high-efficiency filtration device and filtration method described in the present invention. Tetrahydrofuran is selected as the filtering solvent. Because tetrahydrofuran solvent is highly toxic and volatile, it is generally only used for quick cleaning and dissolving asphalt, and is rarely used for filtering asphalt. In this embodiment, since the filtration is carried out in a closed environment, the harm caused by its volatility can be effectively avoided, and the characteristic of rapidly dissolving asphalt can be fully utilized. The specific steps are as follows:

[0061] Step 1: Put 1g of rubber powder modified asphalt in filter cartridge 5, and put 60ml of tetrahydrofuran into container 2;

[0062] Step 2: Turn on the temperature-adjustable electric furnace 1 until the temperature reaches the boiling point of tetrahydrofuran, vaporize the tetrahydrofuran in the container 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com