Electric desalting and dehydrating device, and electric desalting and dehydrating method

A technology of electric desalination and dehydration and electrode plate, applied in the field of electric desalination and dehydration, can solve the problems of poor electric desalination and dehydration, the extra space occupied by the reverse water injection pipe, etc., to achieve the effect of improving the effect, uniform flow and slow flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

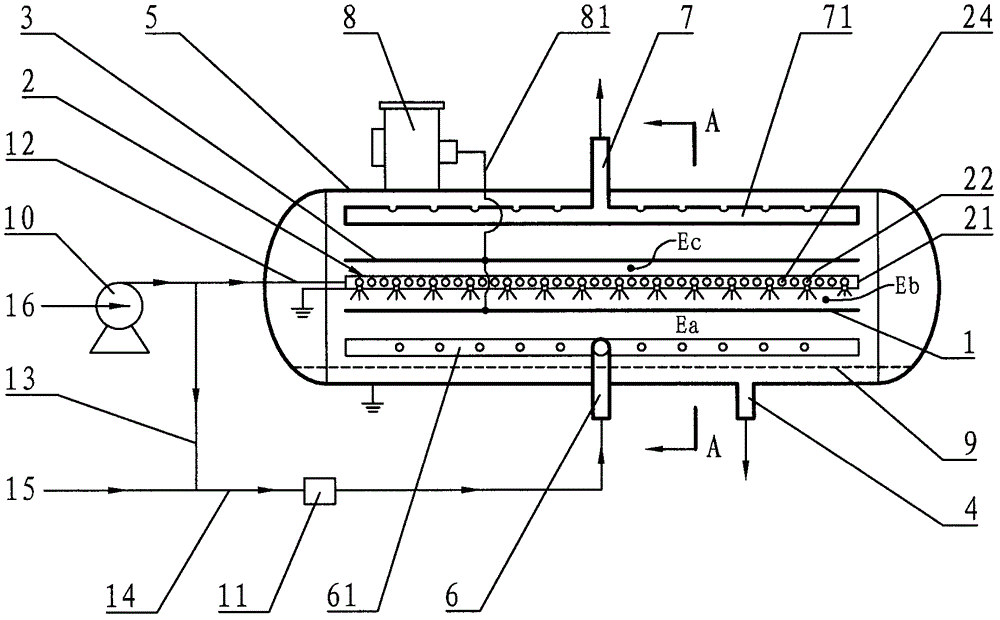

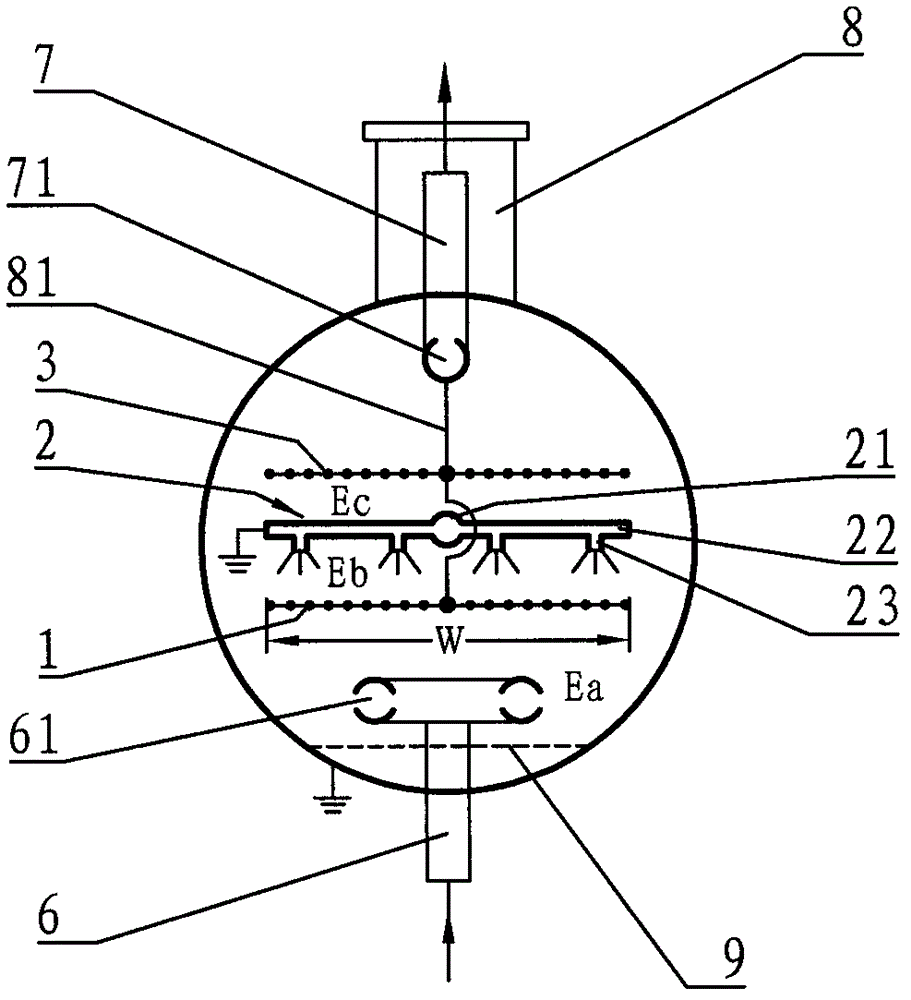

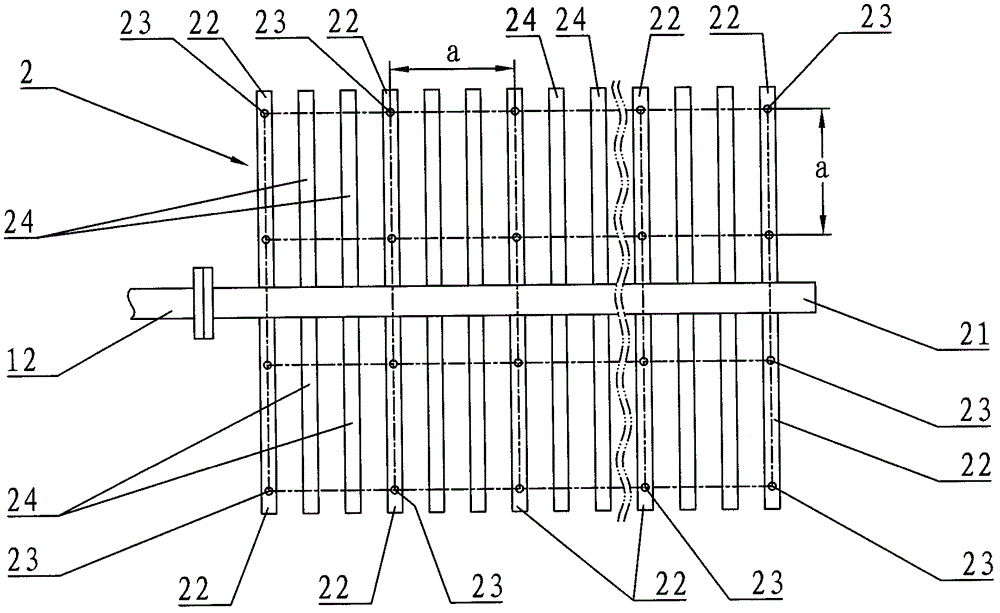

[0017] see figure 1 , figure 2 , Figure 5 with Image 6 , The electric desalination dehydrator of the present invention is provided with a horizontal tank body 5 and a transformer 8 . The bottom of the tank body 5 is provided with an inlet pipe 6 and a drain pipe 4, and the top of the tank body 5 is provided with an oil outlet pipe 7. Two or three layers of electrode plates are horizontally arranged in the tank body 5, and the electrode plates are horizontal electrode plates. The inlet pipe 6 and the oil outlet pipe 7 are usually arranged in the middle of the axial length of the tank body 5; The upper collector 71 is connected. The inlet of the inlet pipe 6 is connected with the oil inlet pipe 14, and the oil inlet pipe 14 is provided with a mixer 11 . Distributor 61 and collector 71 all can use various commonly used types, figure 1 , figure 2 , Figure 5 with Image 6 All shown are tubular. Mixer 11 can use various commonly used mixers, such as SL type, SK type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com