Semiconductor device with voltage-withstanding structure and manufacturing method thereof

A voltage-resistant structure and semiconductor technology, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as poor voltage resistance performance, achieve the effects of reducing production costs, utilizing device area, and ensuring voltage resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

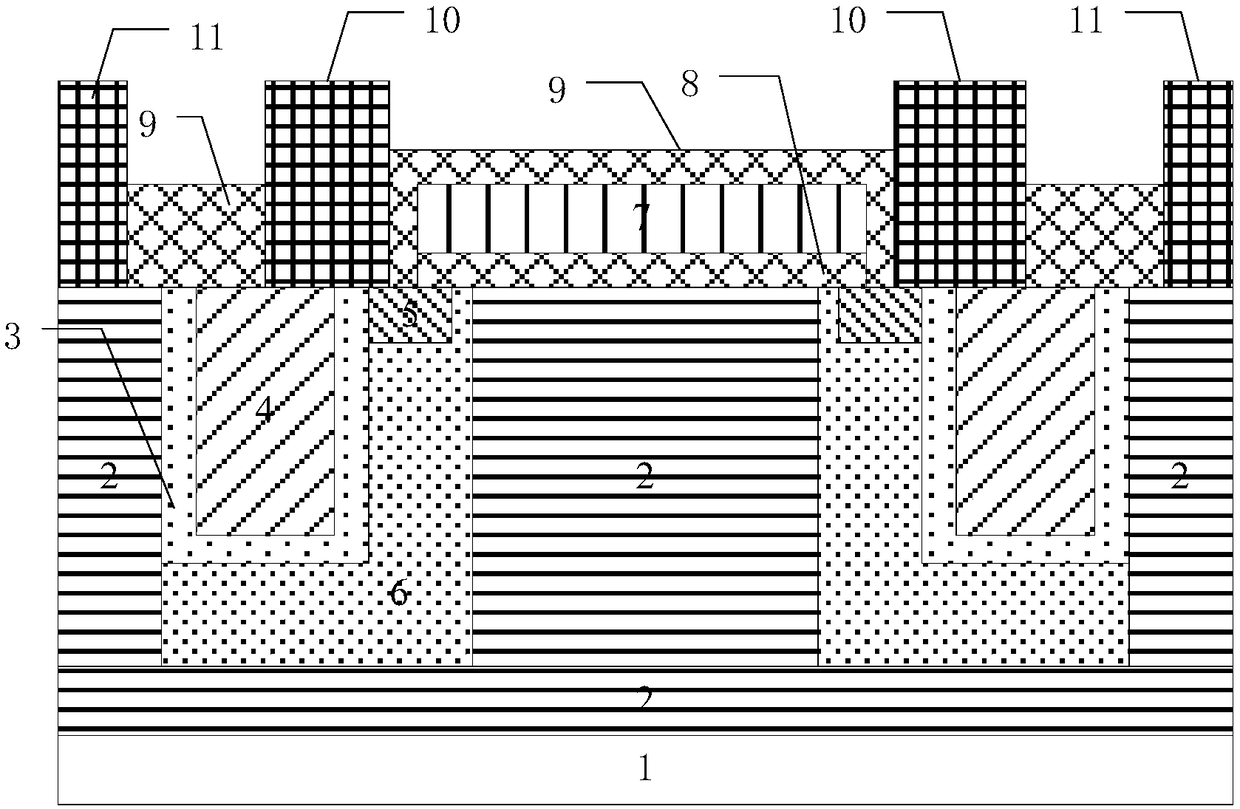

[0038] see figure 1, a cross-sectional view of a semiconductor device with a withstand voltage structure provided by an embodiment of the present invention. A semiconductor device with a voltage-resistant structure provided by an embodiment of the present invention includes: an N-type substrate 1, an N+ region 2, a P- body region 6, a voltage-resistant oxide layer 3, a polysilicon region 4, an N+ source region 5, a gate Extreme oxide layer 8, polysilicon gate 7, dielectric layer isolation 9, device source metal 10 and device drain metal 11. Wherein, the withstand voltage oxide layer and the polysilicon region constitute the withstand voltage structure of the semiconductor device. The N+ region is an electron drift region composed of a central region, a bottom region and a side region. The cross-section of the side area is "mouth", the cross-section of the central area is "one", located in the center of the side area, and the bottom area is square, located at the bottom of th...

Embodiment 2

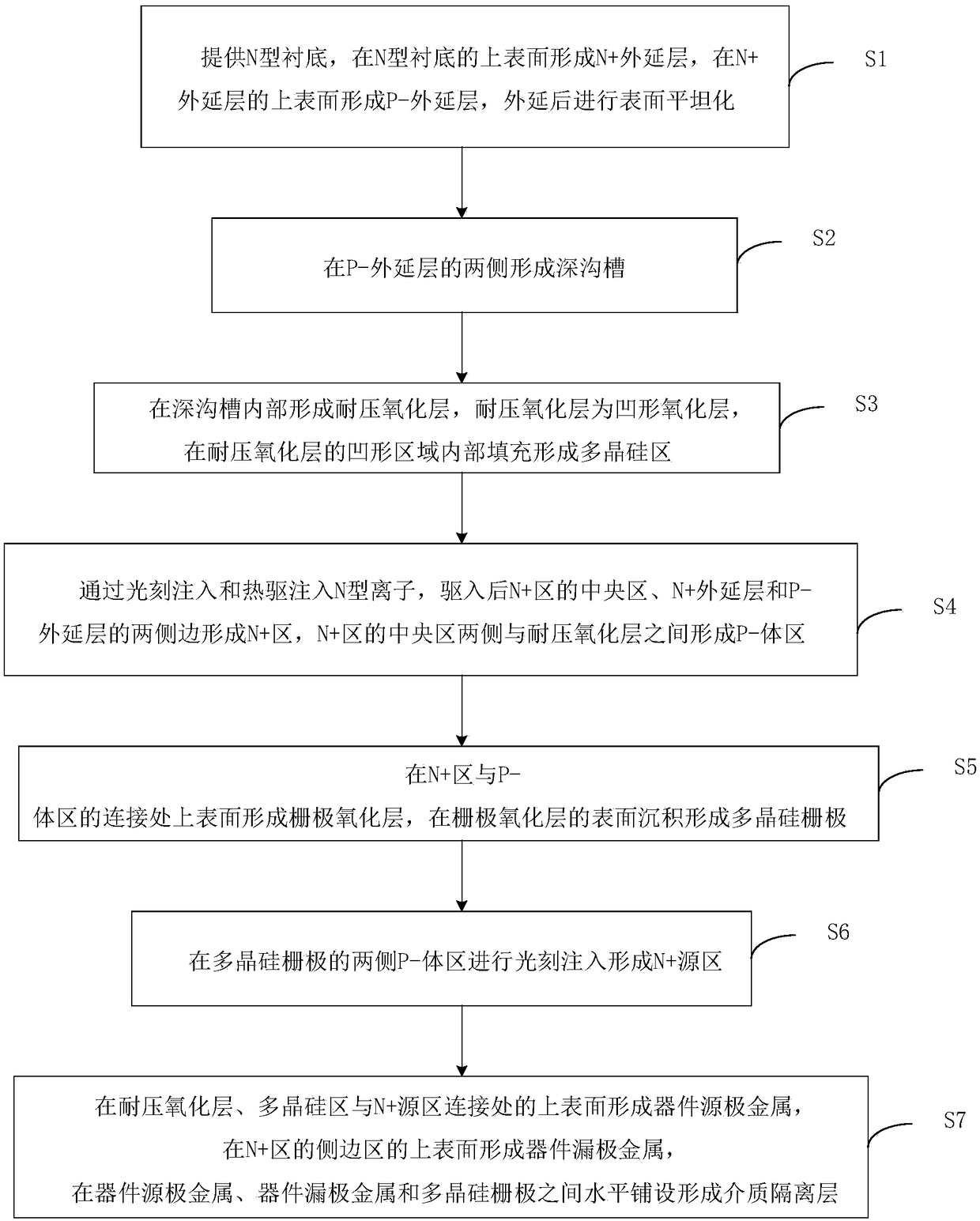

[0048] A method for manufacturing a semiconductor device with a withstand voltage structure provided by an embodiment of the present invention includes the following steps:

[0049] Step S1: providing an N-type substrate, forming an N+ epitaxial layer on the upper surface of the N-type substrate, forming a P- epitaxial layer on the upper surface of the N+ epitaxial layer, and performing surface planarization after epitaxy. see image 3 , a product schematic diagram of step S1 in the method for manufacturing a semiconductor device with a voltage-resistant structure provided in an embodiment of the present invention.

[0050] Step S2: forming deep trenches on both sides of the P- epitaxial layer. see Figure 4 , a product schematic diagram of step S2 in the method for manufacturing a semiconductor device with a voltage-resistant structure provided in an embodiment of the present invention.

[0051] Step S3: forming a voltage-resistant oxide layer inside the deep trench, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com