Improved oilfield downhole electromagnetic flowmeter

An electromagnetic flowmeter, oil field well technology, applied in the field of downhole flow measurement in the oil field, can solve the problems of poor pressure resistance and easy damage, and achieve the effects of improved pressure resistance, shortened length and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

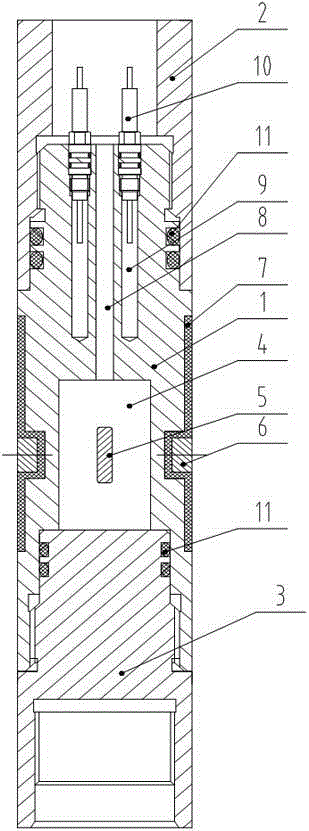

[0018] Such as figure 1 As shown, an improved oil field downhole electromagnetic flowmeter of the present invention includes a sleeve 1. One end of the sleeve 1 is a solid structure, and the other end is a hollow structure. The solid end of the sleeve 1 is connected with a circuit barrel 2, and the circuit The cylinder 2 is provided with electrical components such as excitation coil excitation, electrode plate measurement signal reception, amplification and processing circuits; the hollow end of the sleeve 1 is connected with a lower sealing joint 3, which is connected to the lower centralizer, and the sleeve 1 The hollow structure and the lower end sealing joint 3 form an excitation coil placement chamber 4, and an excitation coil skeleton 5 is arranged in the excitation coil placement chamber 4, and two inner coil skeletons 5 are arranged on the outer side of the sleeve 1 corresponding to the excitation coil skeleton 5. The storage tank for the concave electrode sheet 6, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com