High-strength steel material having excellent low-temperature strain aging impact properties and method for manufacturing same

A technology of strain aging and impact characteristics, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of increased cold deformation, reduced use ambient temperature, reduced toughness and toughness, and achieved excellent low temperature strain aging impact characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0079] Hereinafter, the present disclosure will be specifically described through the following examples. However, it should be noted that the following embodiments are only for describing the present disclosure in detail by way of illustration, and are not intended to limit the scope of rights of the present disclosure. The reason is that the scope of rights of the present disclosure is determined by the subject matter described in the claims and reasonably inferred therefrom.

[0080] (Example)

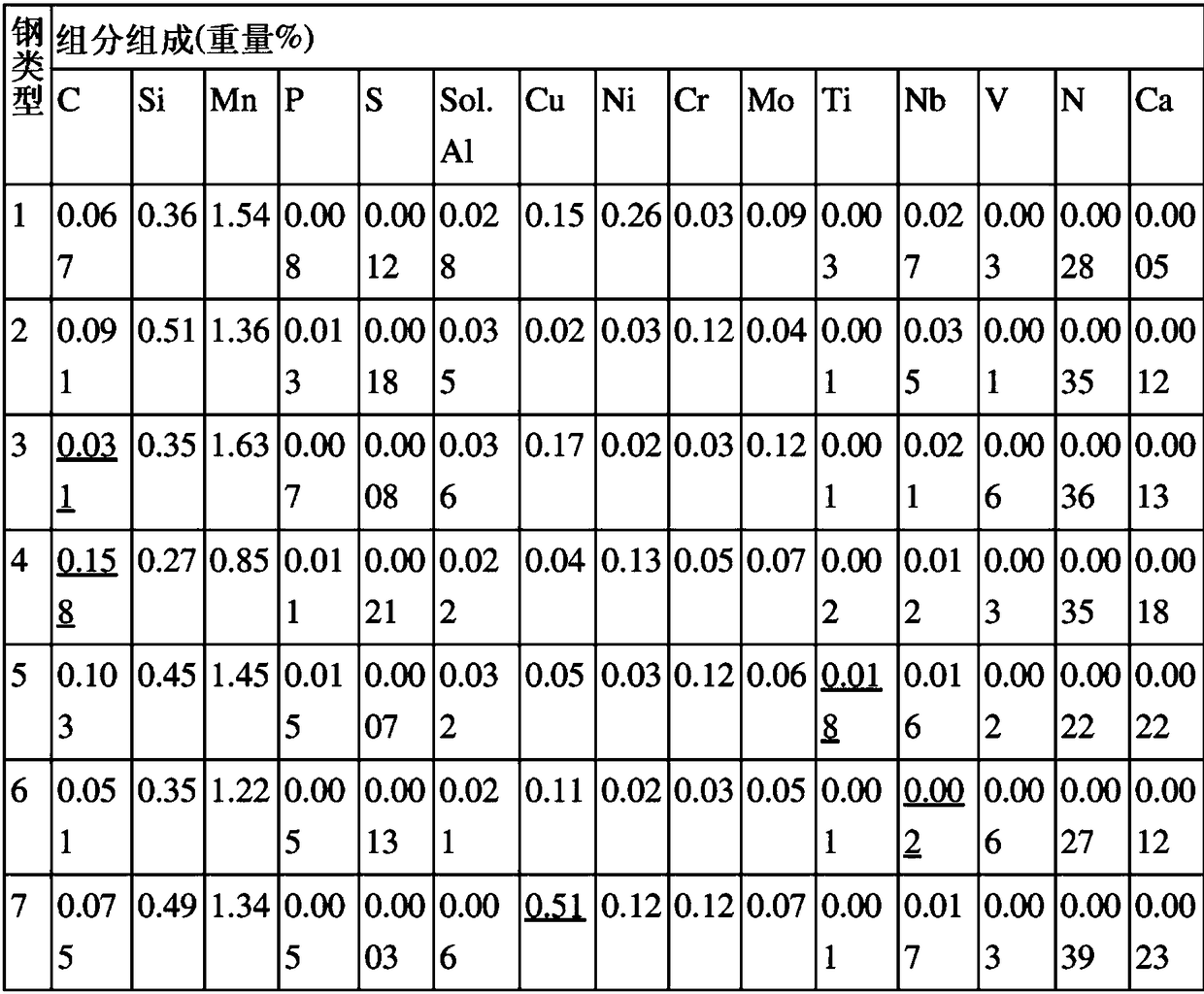

[0081] Steel slabs having the composition shown in Table 1 below were subjected to reheating, hot rolling, and normalizing heat treatment under the conditions shown in Table 2 below, thereby producing hot-rolled steel sheets having a final thickness of 6 mm or more.

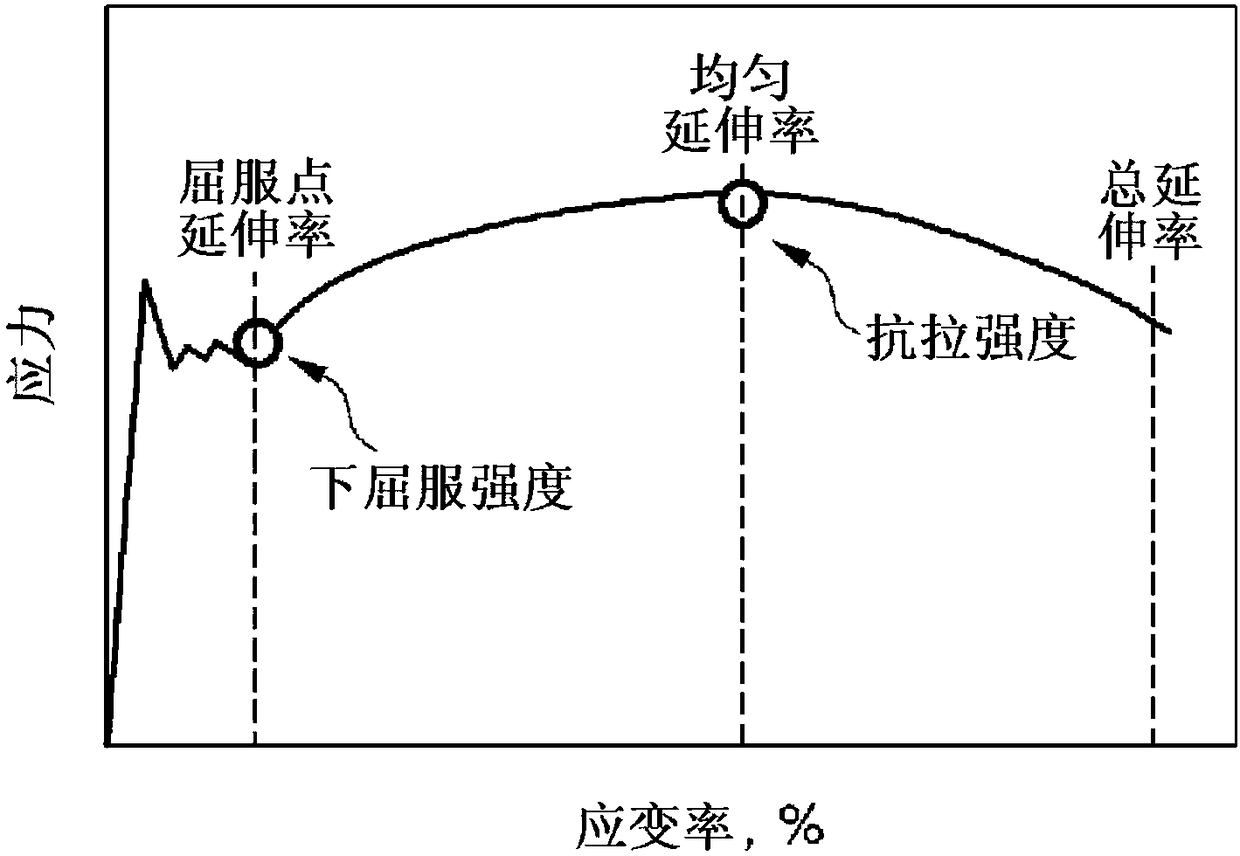

[0082] The microstructural fraction, size and carbonitride fraction of each fabricated hot-rolled steel sheet were measured. In addition, the Charpy impact transition temperature, which can represent the strength (te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com