Double-sided pressure-sensitive adhesive tape

An adhesive tape, double-sided technology, applied in the direction of adhesives, film/sheet adhesives, layered products, etc., can solve the problems of wrinkles, adhesion, insufficient curing speed of the printing layer, etc., to achieve difficult yellowing, simple and convenient Manufactured, easily tuned effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples. In the following description, "parts" are "parts by mass".

[0064]

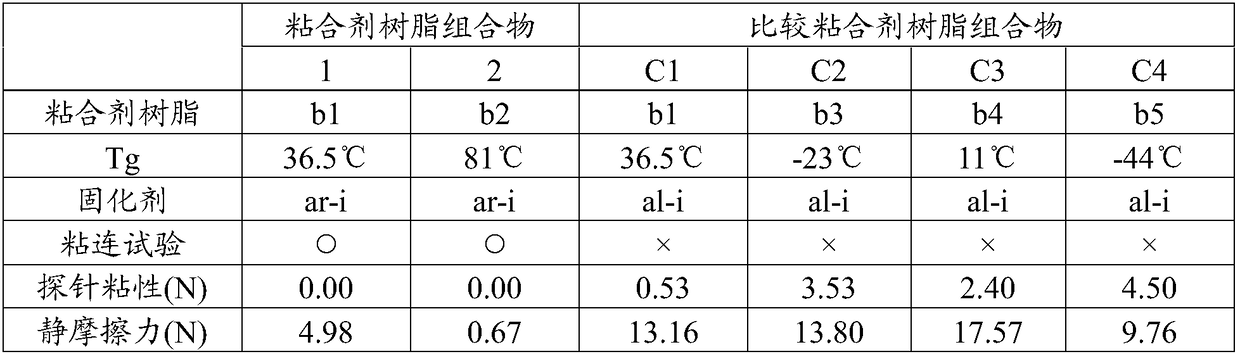

[0065] With respect to 100 parts of the binder resin shown in Tables 1 and 2, 13.0 parts of the curing agent were mixed to obtain binder resin compositions 1 to 3 and comparative binder resin compositions C1 to C7. Among the glass transition temperatures (Tg) described in the tables, the Tg of the binder resin b1 is a DSC measurement value, and the glass transition temperatures (Tg) of the binder resins b2 to b5 are values obtained from manufacturer information.

[0066] (adhesion test)

[0067] On one side of a transparent PET (polyethylene terephthalate) film having a thickness of 12 μm, the adhesive resin composition was laminated so as to have a thickness of 5 μm to obtain an adhesive coating film with a total thickness of 17 μm. The pressure-sensitive adhesive coating fil...

Embodiment 2

[0101] (Preparation of laminate base material B)

[0102] Except having used the transparent PET film of thickness 6 micrometers, it carried out similarly to the laminated base material A of Example 1, and produced the laminated base material B of total thickness 17 micrometers.

[0103] (Production of double-sided adhesive tape)

[0104] A double-sided adhesive tape with a total thickness of about 60 μm was produced in the same manner as in Example 1 except that the thickness of the adhesive layer was changed to 21 μm using the laminated base material B.

[0105]

[0106] (Preparation of black ink composition 2)

[0107] In addition to using the same aliphatic isocyanate-based curing agent (manufactured by Toyo Ink Co., Ltd., trade name LP Hardener) as the curing agent (al-i) in Comparative Adhesive Resin Composition C1, the black Ink composition 1 was carried out similarly, and black ink composition 2 was prepared.

[0108] (Preparation of laminate base material C)

[...

Embodiment 1 and Embodiment 2

[0121] Regarding Example 1, Example 2, and Comparative Example 1, the static friction force (transparent PET film of the laminated base material to the black printed layer of the laminated base material) was measured by a test method in accordance with JIS K 7125. Specifically, the laminated base material was fixed to the test bench so that the transparent PET film side faced upward. On the other hand, another laminated base material (size: 25 mm×25 mm) was fixed to a slide sheet weighing 200 g. Then, the slide sheet is quietly placed on the test bench in such a way that the transparent PET film surface of the laminate substrate fixed on the test bench is in contact with the black printing layer of the laminate substrate fixed on the slide sheet, at a speed of 300mm / The slide is moved in parallel for 1 minute, and the maximum stress (static friction force) initially obtained is measured. In addition, regarding Comparative Example 2, the static friction force of the white pri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| static friction | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com