Ionic liquid catalyst treating system

A technology of ionic liquid and treatment process, which is applied in the field of ionic liquid catalyst treatment system, and can solve the problems of high level of ionic liquid and toxic microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

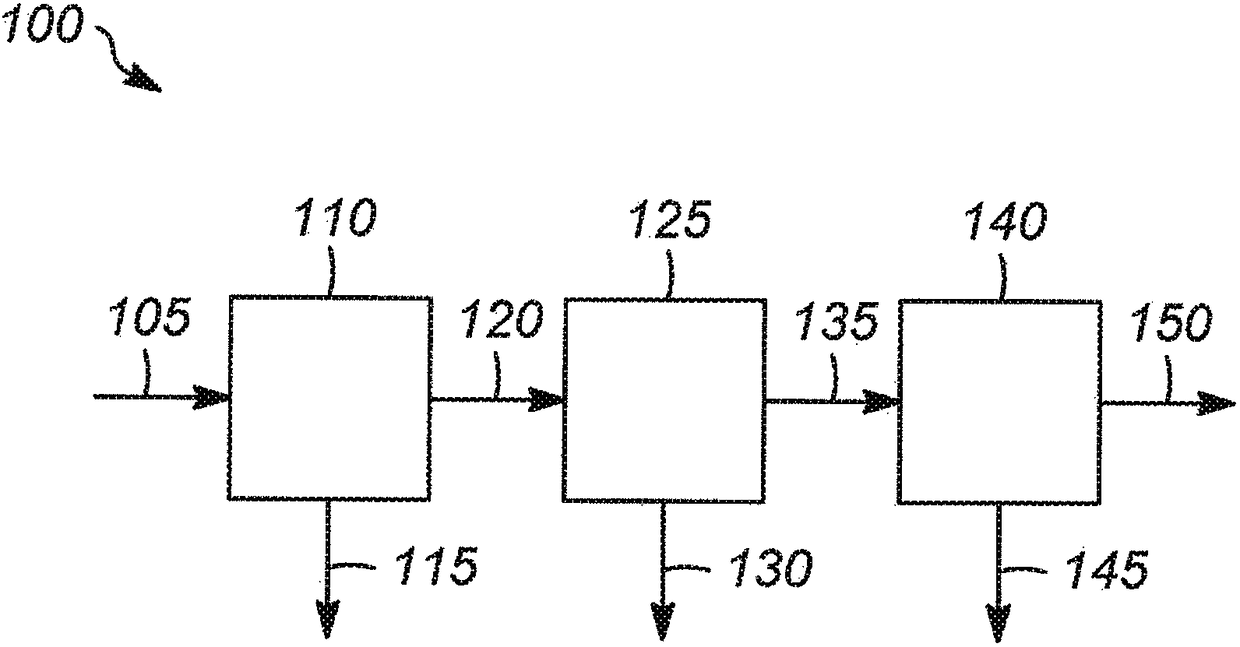

Image

Examples

Embodiment 1

[0038] Add 10.1 g of 1-butyl-3-methylimidazole hexafluorophosphate to 720 g of deionized (DI) water Ionic liquid (BMIM), a pH of 3 was obtained. The solution was then neutralized with 4.9 g of NaOH, forming a solid precipitate of mainly aluminum hydroxide and bringing the pH of the solution to 6. After removing the precipitate by filtration, the solution (containing 0.014 mg ionic liquid / mg solution) was tested for toxicity. The solution's half-maximal effect concentration (EC-50) was then determined for luminescence of Aliivibrio fischeribacteria to assess the toxicity of the solution. The assay EC-50 was achieved at a dilution of 5.7 mg solution / liter water. Therefore, the EC-50 of this ionic liquid is 80 ppB, which is much lower than the level achievable only by combining gravity settling with a coalescer.

Embodiment 2

[0040] To 770 g of deionized (DI) water was added 10.1 g of tributylpentyl Ionic liquid (TBPP) to obtain a pH value of 3. The solution was then neutralized with 4.3 g of NaOH, forming a solid precipitate of mainly aluminum hydroxide and bringing the pH of the solution to 6. After removing the precipitate by filtration, the toxicity of the solution (containing 0.013 mg ionic liquid / mg solution) was determined. The EC-50 of this solution was then determined for the luminescence of Vibrio fischeri bacteria to assess the toxicity of the solution. The assay EC-50 is achieved at a dilution of 1.2 mg solution / liter water. Therefore, the EC-50 of this ionic liquid is 16 ppB, which is much lower than the level achievable only by combining gravity settling with a coalescer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com