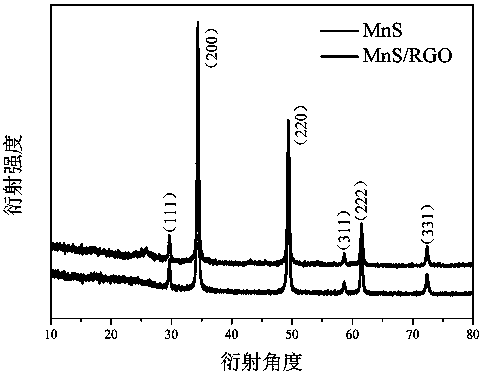

Method for preparing porous manganese sulfide and graphene composite material

A composite material, graphene technology, applied in electrochemical generators, electrical components, battery electrodes, etc., can solve the problems of poor cycle performance and rate performance, material volume collapse, capacity decay, etc., to improve rate performance, improve conductivity. efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. The steps of preparing porous manganese sulfide and graphene composite material are as follows:

[0027] Measure 10 ml of graphene oxide (concentration: 10 mg / ml) into 150 ml of distilled water, and sonicate for 1 hour in an ultrasonic instrument with an ultrasonic power of 45W.

[0028] Then the 50% concentration manganese nitrate solution of weighing 3 g, 3 g L-cysteine, and 0.5 g urea are added in the above-mentioned graphite oxide solution respectively, and this mixed solution is placed on double-display constant temperature magnetic stirrer under magnetic force Stir for 0.5 h. Then the solution was transferred to a reaction kettle, placed in an oven and kept at 160°C for 24 hours.

[0029] After the reaction is finished, cool to room temperature, take out the reaction kettle and open it, wash it with water and ethanol three times respectively, then transfer the intermediate to a vacuum drying oven at 80 degrees for vacuum drying overnight, and then place the ob...

Embodiment 2

[0034] Measure 20 ml of graphene oxide (concentration: 10 mg / ml) into 200 ml of distilled water, and sonicate for 1 hour in an ultrasonic instrument with an ultrasonic power of 45W.

[0035] Then weigh the 50% concentration manganese nitrate solution of 3.58 g, 2.42 g L-cysteine, and 0.60 g urea are added in the above-mentioned graphite oxide solution respectively, and this mixed solution is placed on the double-display constant temperature magnetic stirrer under magnetic force Stir for 0.5 h. Then the solution was transferred to a reaction kettle, placed in an oven and kept at 160°C for 24 hours.

[0036] After the reaction is finished, cool to room temperature, take out the reaction kettle and open it, wash it with water and ethanol three times respectively, then transfer the intermediate to a vacuum drying oven at 80 degrees for vacuum drying overnight, and then place the obtained solid powder in a tube furnace , calcined at 500°C under nitrogen for 4 hours at a heating ra...

Embodiment 3

[0038] Measure 20 ml of graphene oxide (concentration: 5 mg / ml) into 100 ml of distilled water, and sonicate for 1 hour in an ultrasonic instrument with an ultrasonic power of 45 W.

[0039] Then weigh 3.62 g of 50% concentration of manganese nitrate solution, 2.62 g of thiourea, and 0.60 g of urea and add them to the above-mentioned graphite oxide solution respectively, and place the mixed solution on a dual-display constant temperature magnetic stirrer for 0.5 h under magnetic stirring. Then the solution was transferred to a reaction kettle, placed in an oven and kept at 160°C for 24 hours.

[0040] After the reaction is finished, cool to room temperature, take out the reaction kettle and open it, wash it with water and ethanol three times respectively, then transfer the intermediate to a vacuum drying oven at 80 degrees for vacuum drying overnight, and then place the obtained solid powder in a tube furnace , calcined at 300 degrees under nitrogen for 4 hours at a heating ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com